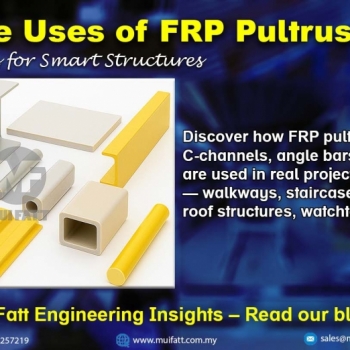

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Rust Problems? Discover Why FRP Roofing Is the Superior Choice

09 May 2025

- Key Takeaways

- The Pain Point: Struggling with Rusted Roof Panels in Harsh Environments?

- Introducing FRP Roofing: A Smart Alternative

- How FRP Roofing Is Made: Pultrusion Explained

- Roofing Material Comparison: FRP vs Metal vs PVC

- Why FRP Roofing Outperforms Metal Roofing in Harsh Environments

- Understanding Your Needs: Is FRP Roofing Right for You?

- Get Rust-Free Protection Today with Our FRP Roofing Solutions!

- Frequently Asked Questions (FAQs)

Key Takeaways

-

Metal roof panels corrode rapidly in harsh environments such as animal farms and chemical plants.

-

FRP roofing offers superior corrosion resistance, durability, and long-term savings.

-

A wide range of FRP roofing profiles are available to match common metal shapes.

-

FRP roofing is cut-to-length for easier, cleaner installation.

-

Ideal for agricultural, industrial, and coastal applications — with real-world results.

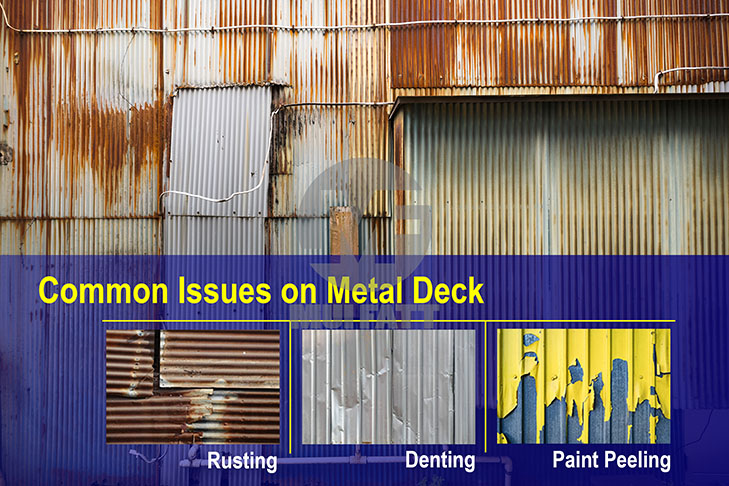

The Pain Point: Struggling with Rusted Roof Panels in Harsh Environments?

If you're operating in a chemical plant, coastal facility, wastewater treatment plant, or animal farm, metal roofing corrosion is not just a nuisance — it’s a serious operational risk.

-

Rapid Corrosion: Traditional metal roof panels corrode quickly when exposed to chemical vapors, salt spray, ammonia, or organic acids.

-

High Maintenance Costs: Frequent roof repairs, repainting, and full replacements create a constant financial burden.

-

Operational Downtime: Leaks and structural roof failures can disrupt production or jeopardize animal welfare in farms — causing profit loss.

-

Facility and Product Risks: Water ingress from corroded roofs risks product contamination, machinery damage, and livestock health issues.

Livestock animal farming is highly vulnerable. Facilities like Long-Term Corrosion Protection: FRP Roofing for Pig Farms and Corrosion-Free FRP Solutions for New Chicken Farms have already moved to FRP roofing to solve these critical challenges.

Introducing FRP Roofing: A Smart Alternative

Fiberglass-reinforced plastic (FRP) Roofing offers a permanent solution to harsh corrosion problems, making it ideal for agricultural, industrial, and coastal applications.

-

Profile Variety: We offer a wide range of FRP roofing profiles to match many commonly used metal roof shapes, ensuring smoother replacements or extensions.

-

Cut-to-Length Production: Panels are precisely cut during pultrusion to match your building’s required length, saving time and reducing on-site adjustments.

-

Built to Resist: FRP stays strong under chemical exposure, ammonia gases, organic acids, salt spray, and extreme weather.

Just like in our Cut-to-Length FRP Roofing Supplied for Chemical Plant in Kuantan, these features help streamline your roofing upgrade.

How FRP Roofing Is Made: Pultrusion Explained

Our FRP roofing panels are manufactured through the pultrusion process, guaranteeing uniformity, strength, and resilience.

Pultrusion Process Overview:

-

Continuous fiberglass reinforcement strands are pulled through a resin impregnation system.

-

The material is shaped through heated dies into precise roofing profiles.

-

Resin cures under controlled heat — producing a rigid, high-strength composite panel.

-

Finished roofing panels are cut to your required lengths.

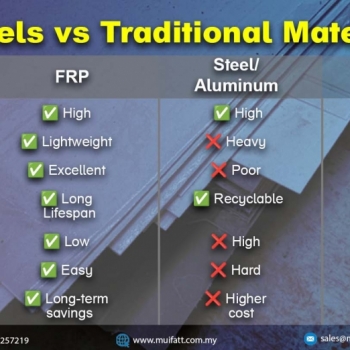

Roofing Material Comparison: FRP vs Metal vs PVC

| Features | FRP Roofing | Metal Roofing | PVC Roofing |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor (prone to rust, ammonia corrosion) | Moderate (chemical-sensitive) |

| Durability | High | Moderate | Moderate |

| Maintenance | Minimal | Frequent | Occasional |

| Customization | Cut-to-size, Profile match | Limited options | Limited options |

| Weight | Lightweight | Heavy | Lightweight |

| UV Resistance | High | Coating needed | Low |

| Cost Efficiency (Long-term) | High savings | Costly maintenance | Shorter lifespan |

Why FRP Roofing Outperforms Metal Roofing in Harsh Environments

FRP roofing is engineered to thrive where metal fails:

-

No Rust or Corrosion: FRP remains unaffected by ammonia, acids, saltwater, and chemical vapors.

-

Superior Longevity: Even in livestock farms, fertilizer facilities, and coastal plants, FRP delivers decades of reliable service.

-

Minimal Downtime: No leaks, fewer repairs — operations stay smooth.

-

True Investment Value: Slightly higher upfront cost, but massive savings in maintenance, replacements, and downtime costs.

In animal farming, especially, FRP roofing helps ensure better livestock comfort, safer environments, and operational efficiency.

Understanding Your Needs: Is FRP Roofing Right for You?

FRP roofing could be the right investment if:

-

You operate in corrosive environments such as animal farms, fertilizer plants, or coastal areas.

-

You face frequent roof leaks or corrosion repairs disrupting your work or livestock health.

-

You want to replace metal roofs without modifying your structural design — our profile range matches many common metal types.

-

You seek a durable, low-maintenance roofing solution with a long lifespan and excellent chemical resistance.

Our extensive project experience — from pig farms to chemical plants — proves the real-world performance of FRP.

Get Rust-Free Protection Today with Our FRP Roofing Solutions!

Tired of battling rust and endless roof repairs? Future-proof your facility with our customizable, corrosion-proof FRP Roofing Panels — built for the harshest agricultural, industrial, and coastal environments. Explore Our FRP Roofing Products or contact us now via WhatsApp or email at sales@muifatt.com.my for a Free Consultation!

Let us help you design a roofing solution that meets your real-world needs — and protects your future growth.

Frequently Asked Questions (FAQs)

Can FRP roofing match my existing metal roof profile?

We offer a variety of FRP roof profiles designed to match many standard metal roofing shapes used in Malaysia, enabling easy replacements and extensions without structural redesign.

How long does FRP roofing typically last in highly corrosive environments?

With proper installation, FRP roofing can last for a long time, potentially several decades, even in extreme chemical, salt, or ammonia-rich atmospheres.

How does FRP roofing weight compare to metal?

FRP roofing is lightweight yet strong, reducing structural load and allowing faster, safer installation compared to heavy metal sheets.

Is FRP roofing suitable for animal farming, such as pig farms and chicken farms?

Absolutely. FRP’s resistance to ammonia gas and organic acids makes it perfect for agricultural buildings, livestock farms, and poultry houses.

#FRProofing #rustfreeroofing #roofingforcorrosiveindustries #FRPvsmetalroofing #FRPpultrusionroofing #FRProofingMalaysia #industrialroofreplacement #pultrudedFRProofpanels

Disclaimer:-

The content on this site is for general information and entertainment purposes and does not constitute legal counsel. We strive to keep our information as accurate as possible. However, we make no warranties about the completeness, accuracy, reliability, suitability, or availability with respect to the information contained on this page. You should rely on this information at your own risk. This website may include links to other third-party sites. These links are provided as a convenience to you as a reader, user, or browser only. We make no representation, warranty, or guarantee, nor do we endorse or take responsibility for any of the content of such sites.

Stay in touch with us if you’re interested in hearing from us promptly.

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

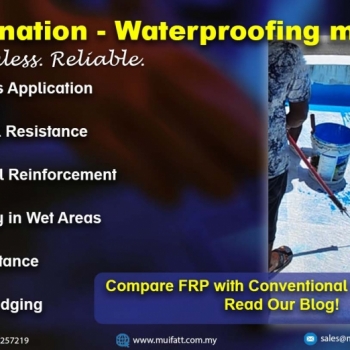

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

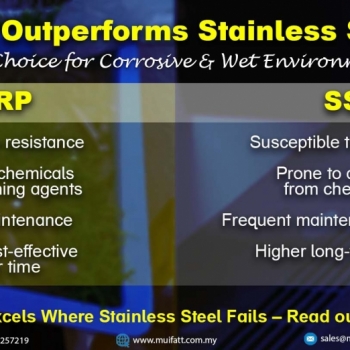

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.