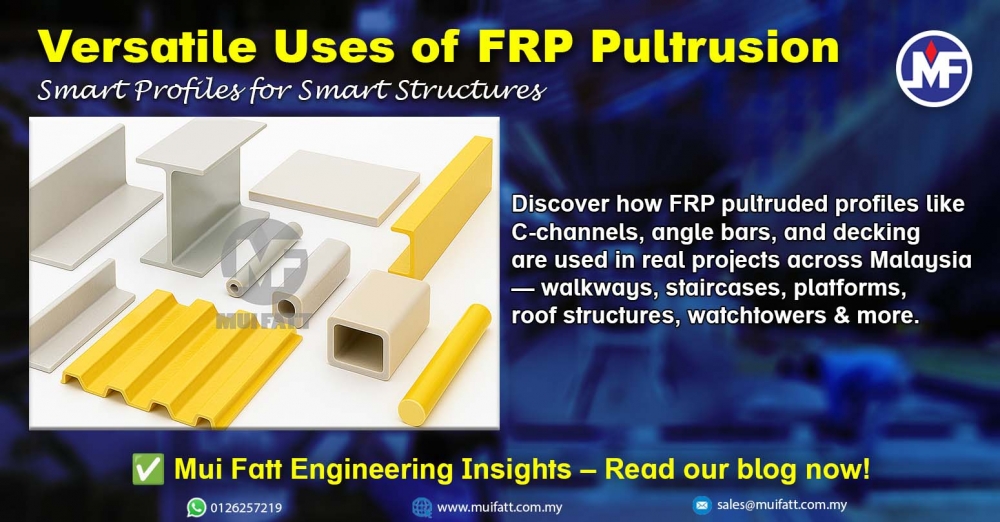

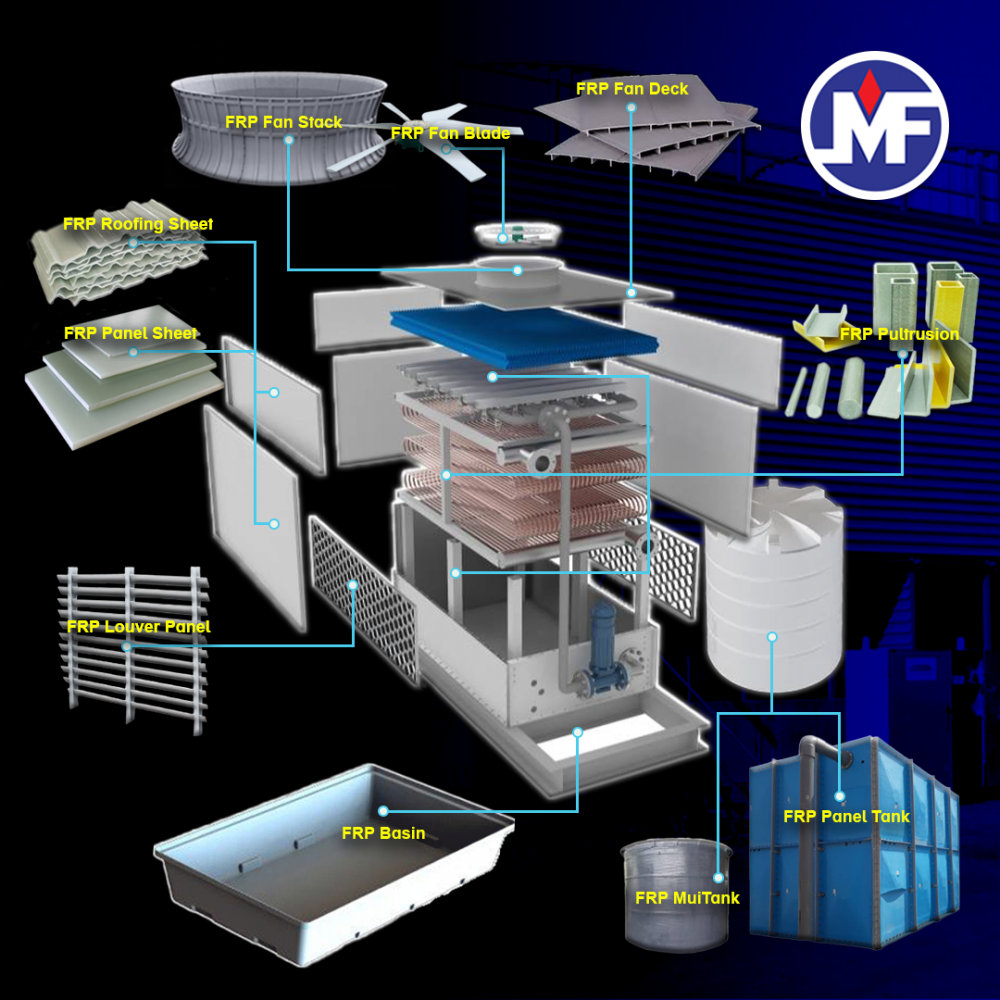

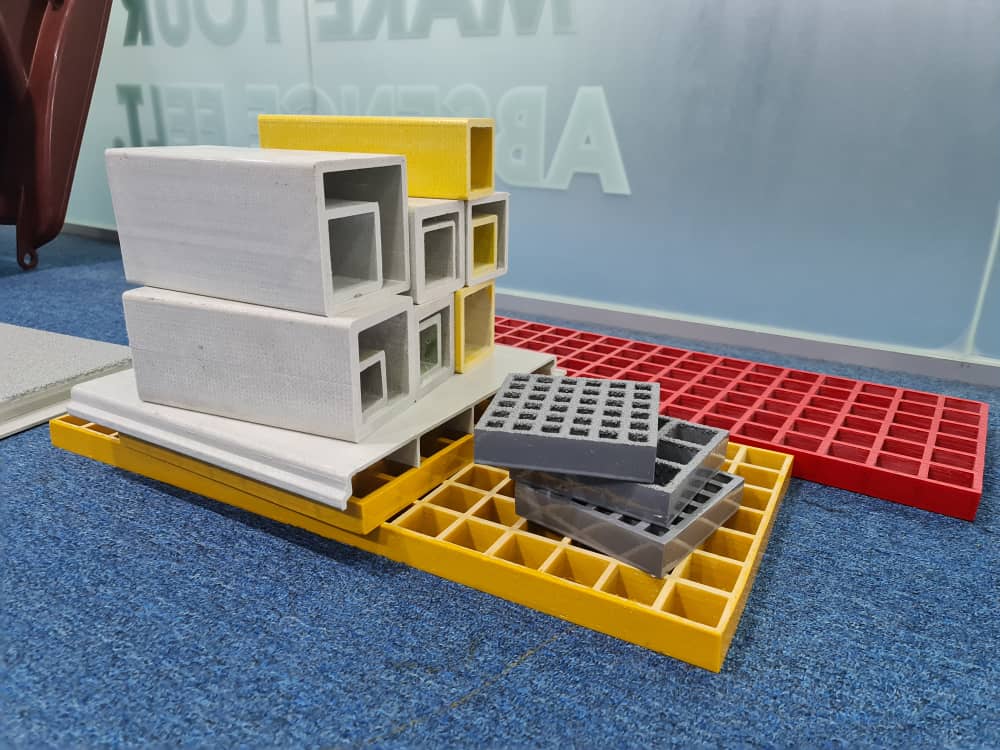

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Discover Insights on FRP & Industrial Solutions

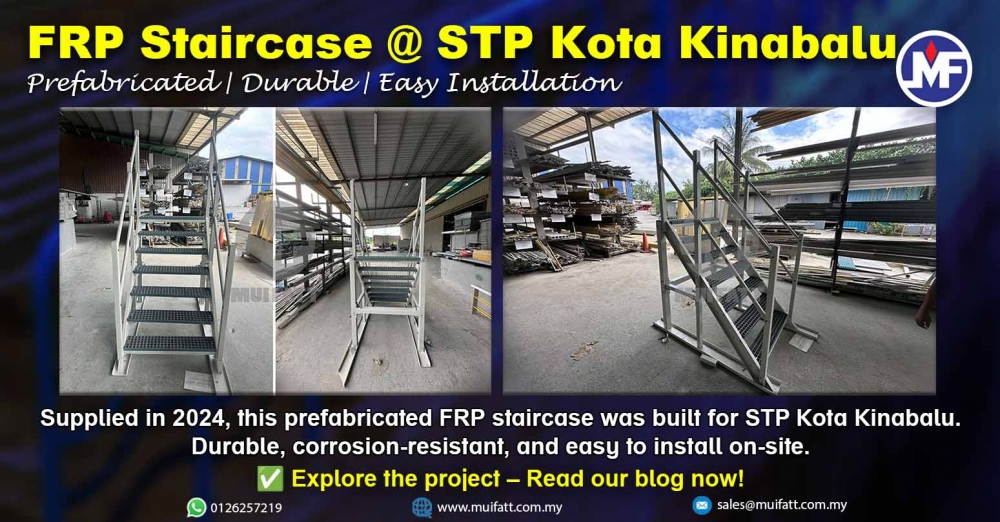

In 2024, we successfully supplied a fully assembled FRP staircase to a sewage treatment plant (STP) in Kota Kinabalu via sea freight. Constructed using high-strength FRP pultruded profiles and molded grating, this custom-built solution provides long-term durability, corrosion resistance, and ease of installation—making it ideal for harsh wastewater environments.

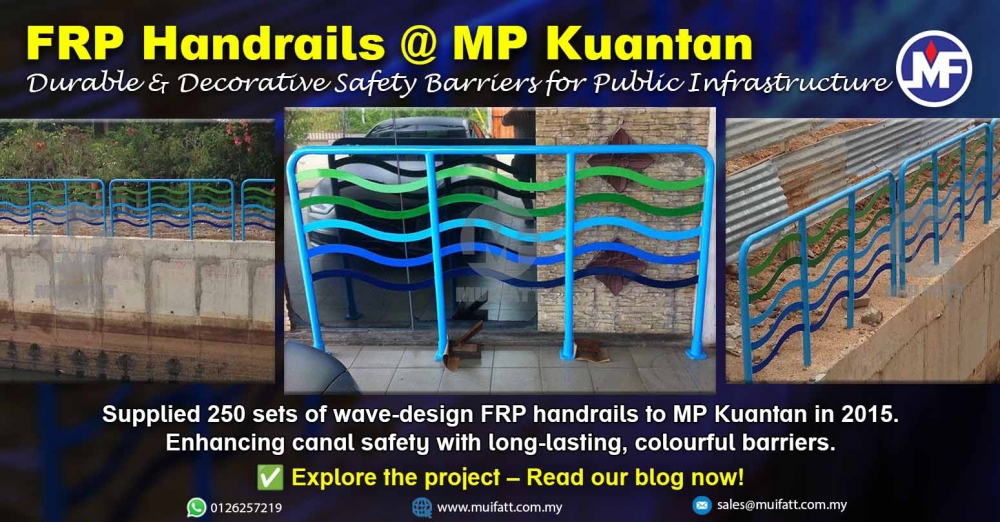

In September 2015, Mui Fatt supplied approximately 250 sets of wave-designed FRP pultruded handrails to Majlis Perbandaran Kuantan via Kerjaya Kibar Sdn Bhd. Installed at various canal-side locations, these handrails were chosen for their superior durability, corrosion resistance, and maintenance-free performance in outdoor environments. This project reflects our commitment to safety, functionality, and urban aesthetics using long-lasting FRP solutions.

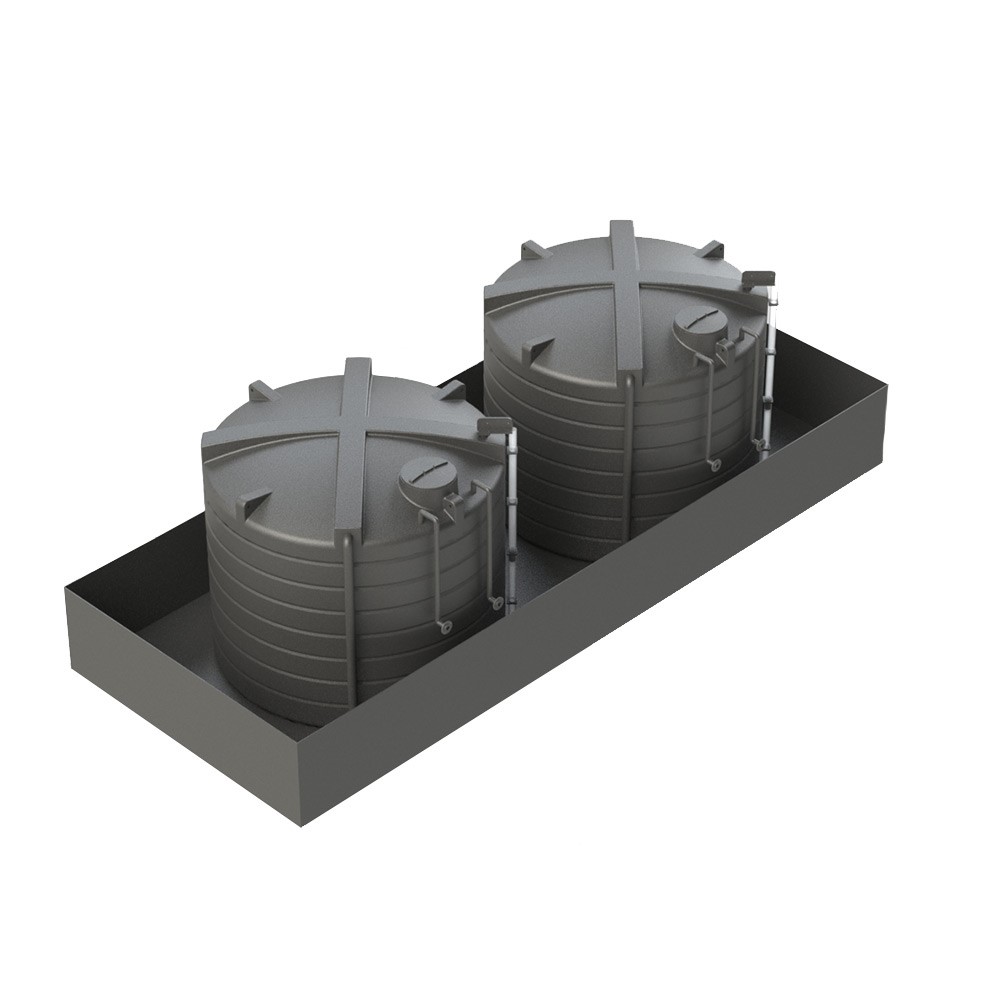

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

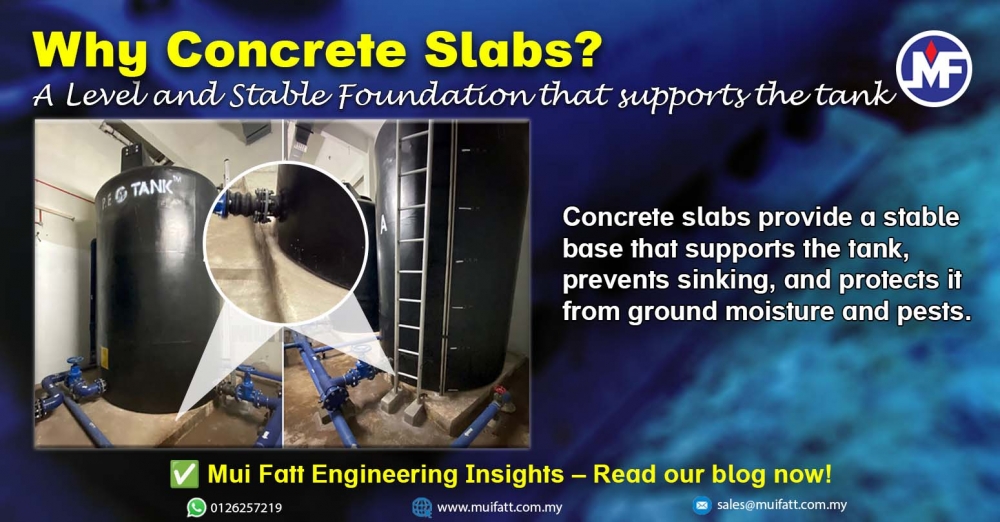

Understand the key differences between concrete slabs used for water tanks and septic tanks. Learn about their functions, compliance standards, structural needs, and when to use each, so you can make the right decision for a safe and long-lasting installation.

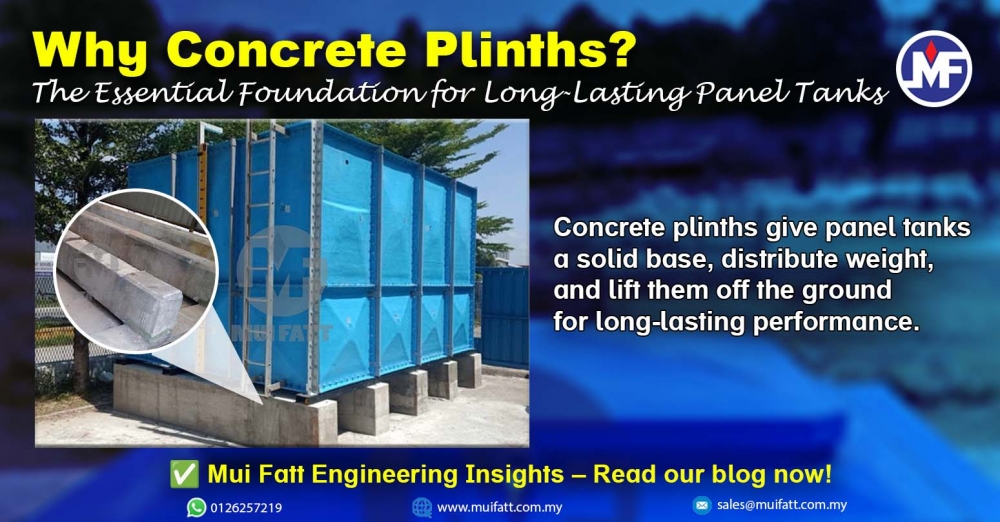

Compare concrete plinths and slabs to understand their roles in water, septic, and sectional tank installations. Learn key differences in design, application, and compliance.

Concrete slabs provide stability and safety for water and septic tanks. This blog explains why they are essential, whether they are mandatory, and how they impact installation and maintenance.

Explore the essential role of concrete plinths and C-channels in sectional panel tanks. Learn why they’re standard, how they enhance stability and maintenance, and how Malaysia’s regulations influence their use.

The Klinik Kesihatan 2 Sendayan project aimed to provide a reliable, space-efficient water storage solution. Our GRP sectional panel tank, pre-installed and ready for use, ensures minimal site disruption and quick commissioning. This project underlines Mui Fatt’s ability to tailor GRP solutions to client specifications, fulfilling both size constraints and capacity requirements.

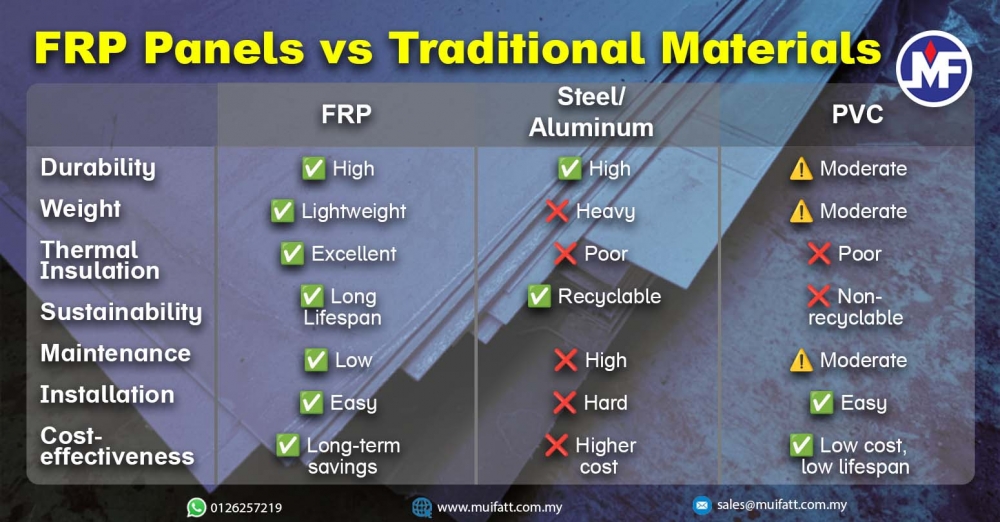

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

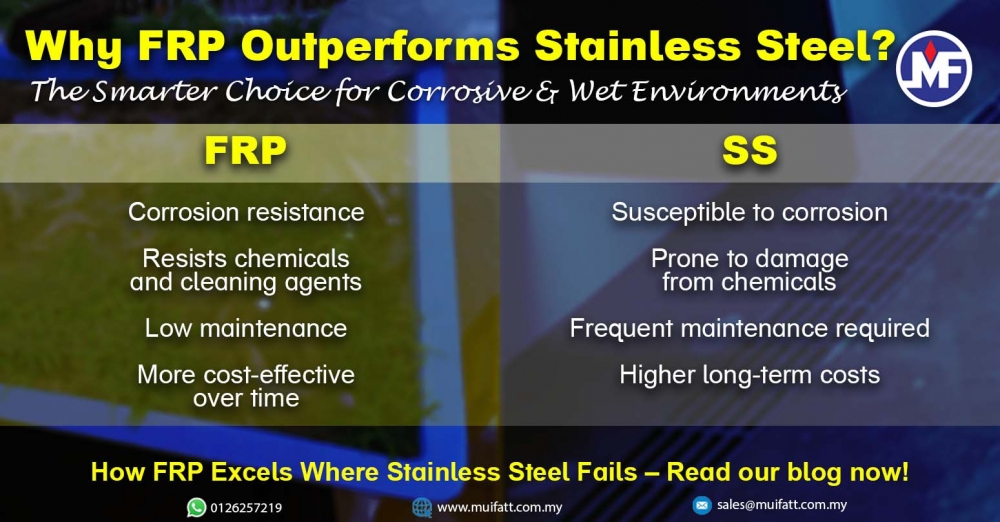

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

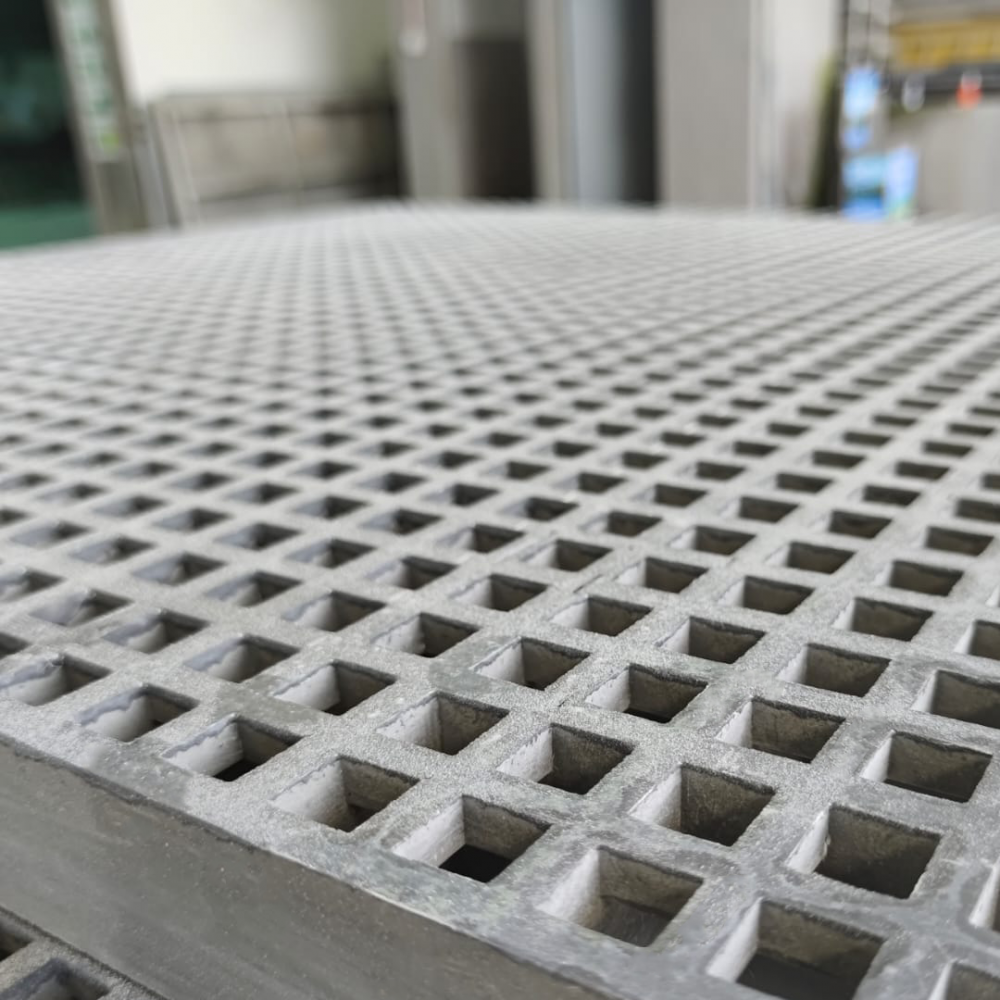

In 2024, Mui Fatt supplied approximately 200m² of MG25-100 grey FRP molded gratings for toilet drain systems at RNR Simpang Pulai and RNR Gurun. This was a major restroom renovation under the PLUS Highway upgrade initiative. Our gratings provided a durable, anti-slip, and corrosion-resistant solution for enhanced public hygiene and long-term service performance.

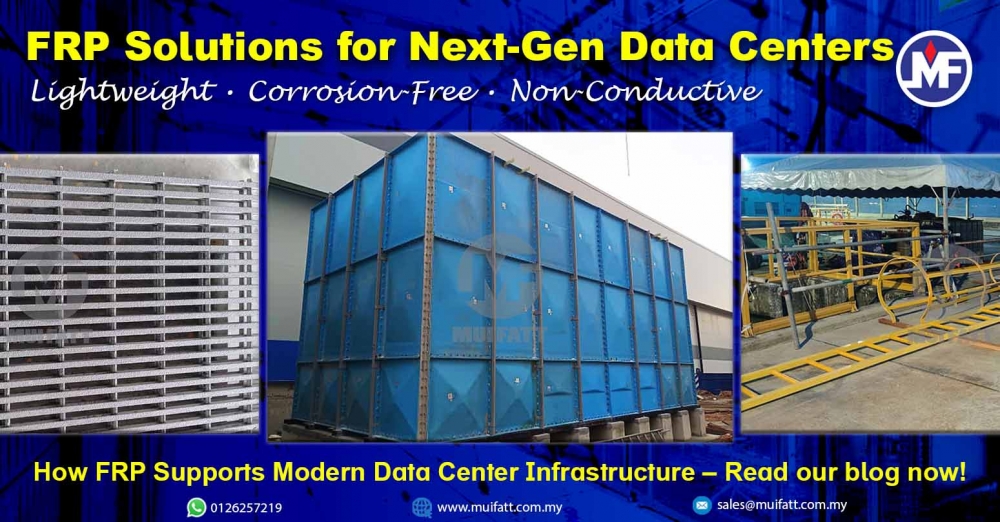

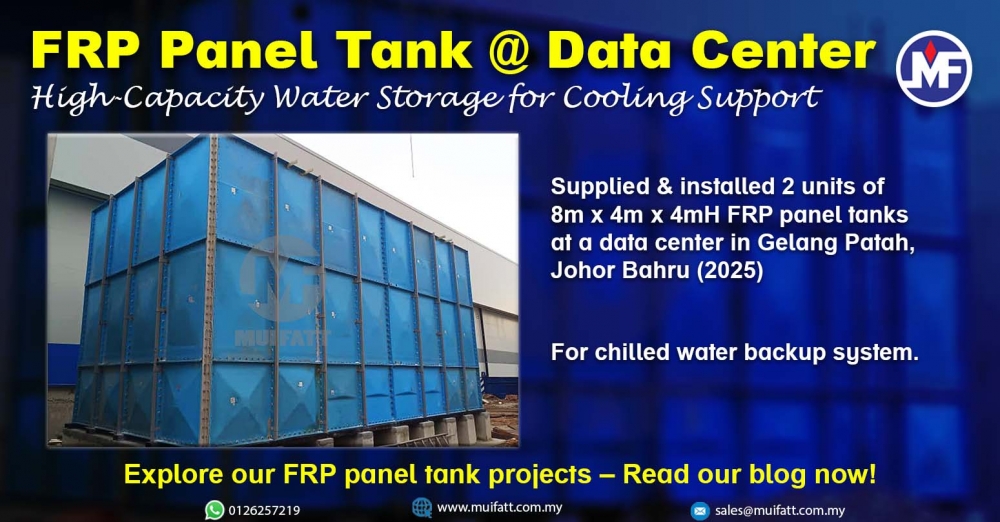

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

In 2025, Mui Fatt successfully supplied two units of FRP sectional panel water tanks, each measuring 8m x 4m x 4mH, for a high-performance data center located in Gelang Patah, Johor Bahru. Delivered via contractor Timesfly International, these tanks ensure safe, large-volume water storage with corrosion-resistant performance tailored for critical facilities like data centers.

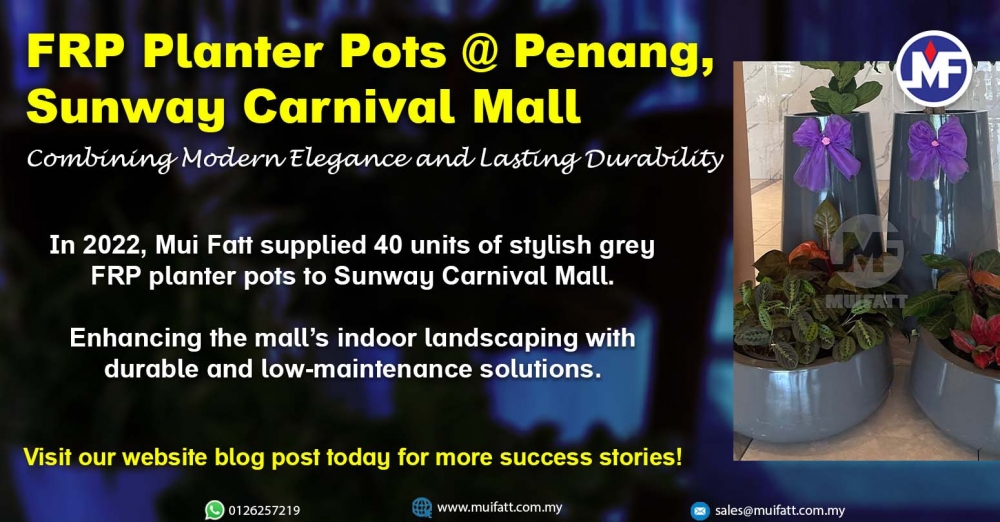

In 2022, Mui Fatt supplied 40 different sizes of grey FRP planter pots to Sunway Carnival Mall for indoor landscaping. This continued collaboration demonstrates Sunway's trust in our FRP products for enhancing their spaces. Read on to learn how our solution met their landscaping goals and the benefits of choosing FRP for mall projects.

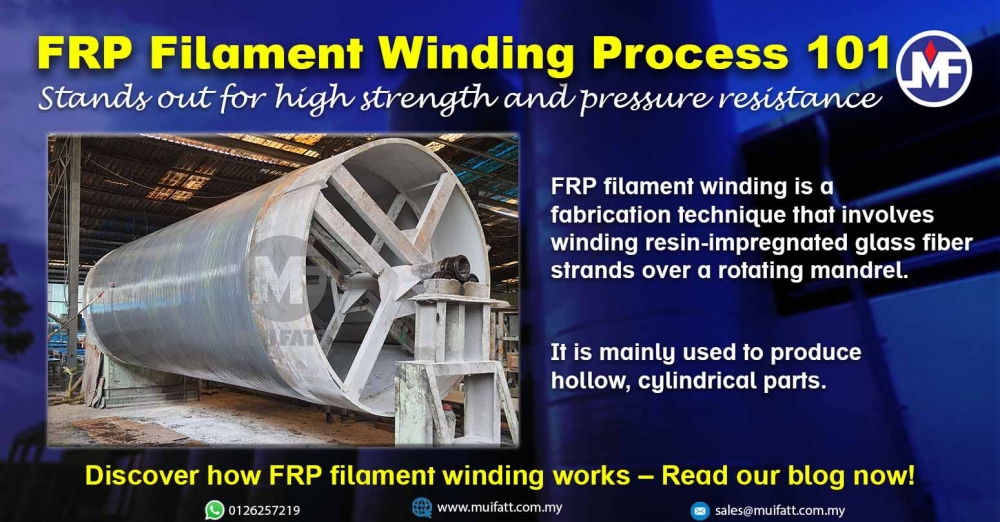

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.

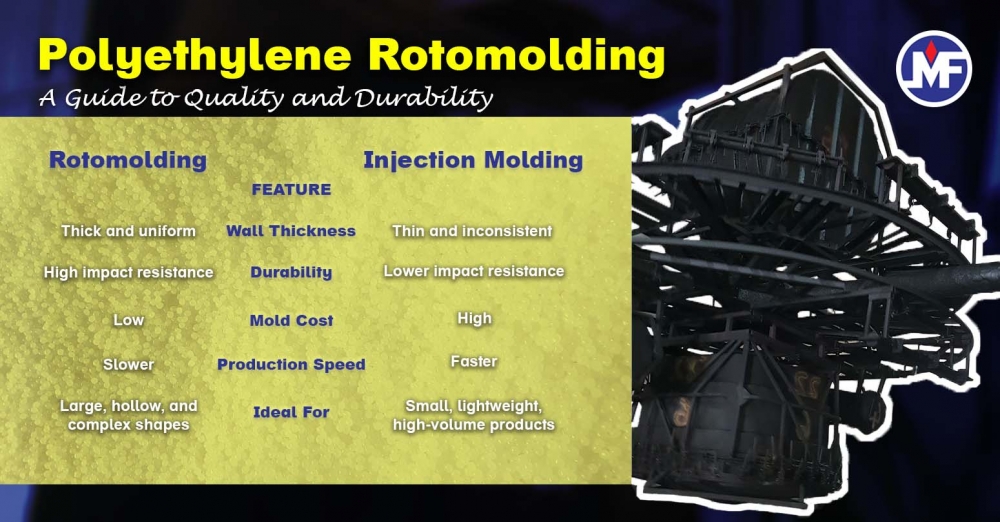

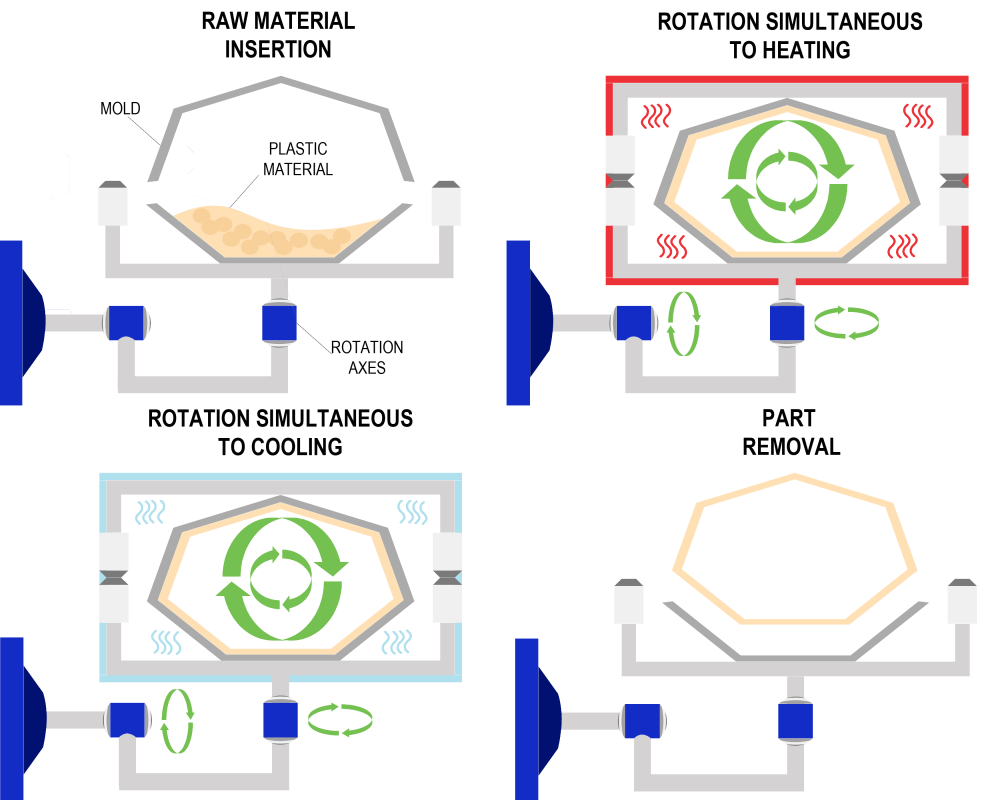

This article explains the polyethylene rotomolding process, compares it with other methods, and helps you decide the best manufacturing approach for your PE product needs.

Working inside FRP or PE tanks, like panel tanks, septic tanks, or SSTS, may involve confined space hazards. Understand why compliance with DOSH regulations is essential for your project’s safety and success.

Tired of dealing with rusted roof panels? Learn how FRP roofing offers a corrosion-free, custom-fit solution — and why it outperforms metal for industrial environments.

Mui Fatt has been the trusted supplier of FRP tanks for Magsoft’s wastewater treatment systems since 2022. These tanks are engineered to resist harsh chemicals and built to meet the unique layout and specifications of each treatment plant.

In 2024, Mui Fatt successfully fabricated and delivered 20 large-size fiberglass-reinforced plastic (FRP) signage boards for use as plantation entrance stands. Designed for high durability, weather resistance, and customization, these signage boards can be adapted for factory and plant usage across industries.

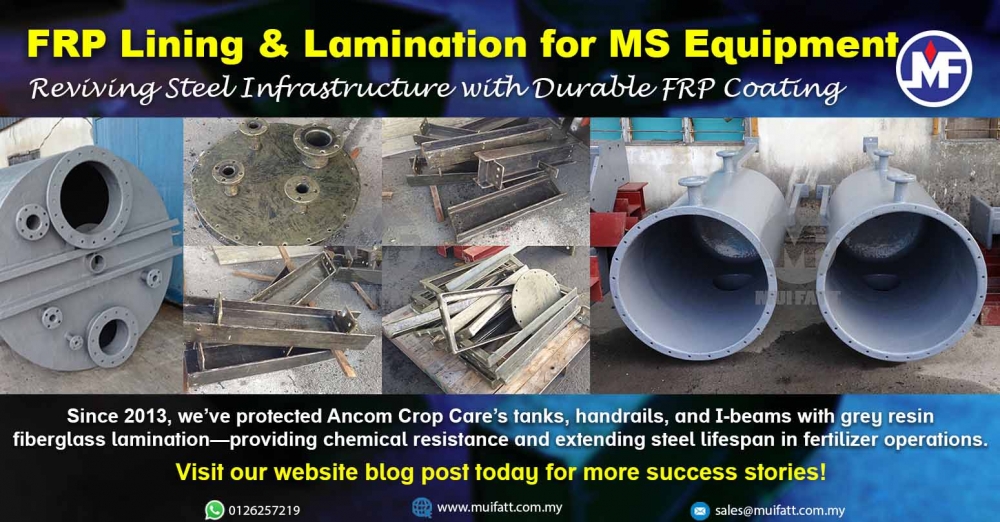

Since 2013, Mui Fatt has delivered long-term corrosion protection for Ancom Crop Care’s fertilizer factory. Our grey-colored FRP lining has been applied to various mild steel structures, such as handrails, I-beams, and chemical tanks, to enhance durability in chemically aggressive environments.

Since 2013, Yinpolin Agriculture Sdn Bhd—a company now known as Hextar Fert Sdn Bhd—has entrusted us with the long-term supply and application of FRP lamination on mild steel structures throughout their chemical fertilizer manufacturing plant. This ongoing collaboration involves laminating handrails, I-beams, and chemical storage tanks using a clear resin coating reinforced with fiberglass mat, effectively protecting these steel components from aggressive corrosion caused by daily chemical exposure. Our fiberglass lining solutions have significantly enhanced the lifespan, structural safety, and operational efficiency of their facility, reinforcing our position as a reliable partner in industrial-grade corrosion protection.

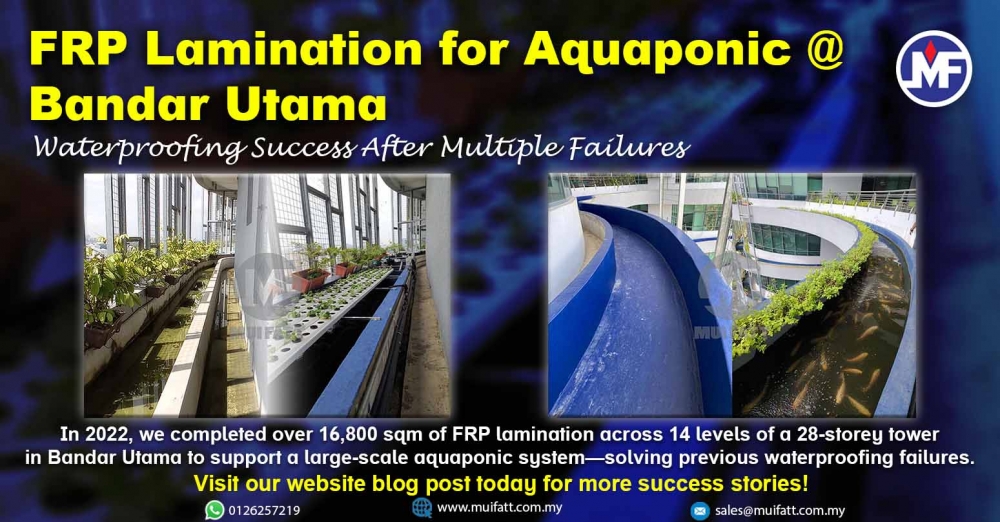

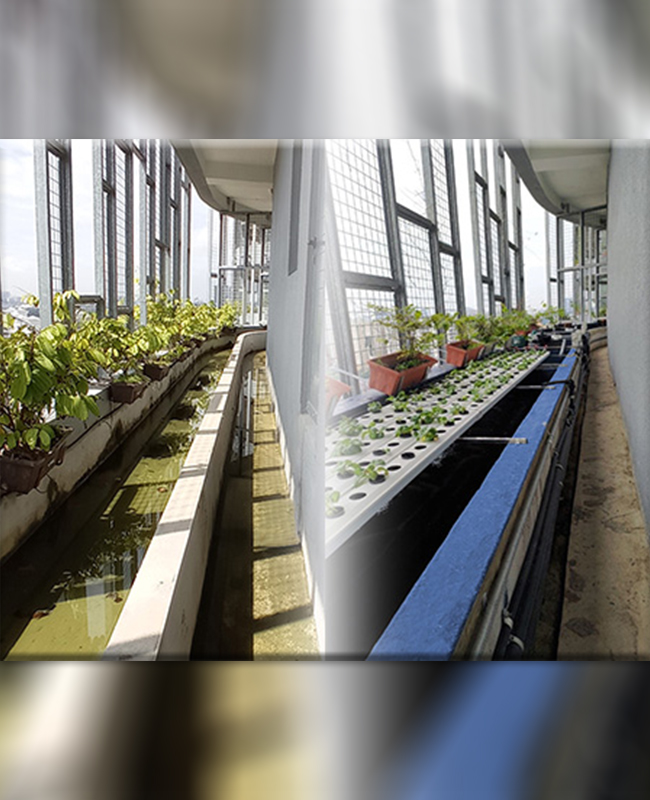

In 2022, Mui Fatt delivered a full-scale FRP lamination solution across 14 levels of a 28-storey building in Bandar Utama to support a commercial aquaponic system. Covering over 16,800 sqm, the project was completed within 3 months and successfully resolved persistent waterproofing issues that had previously failed using other methods. This project underscores the reliability of our FRP solutions in demanding, high-rise environments.

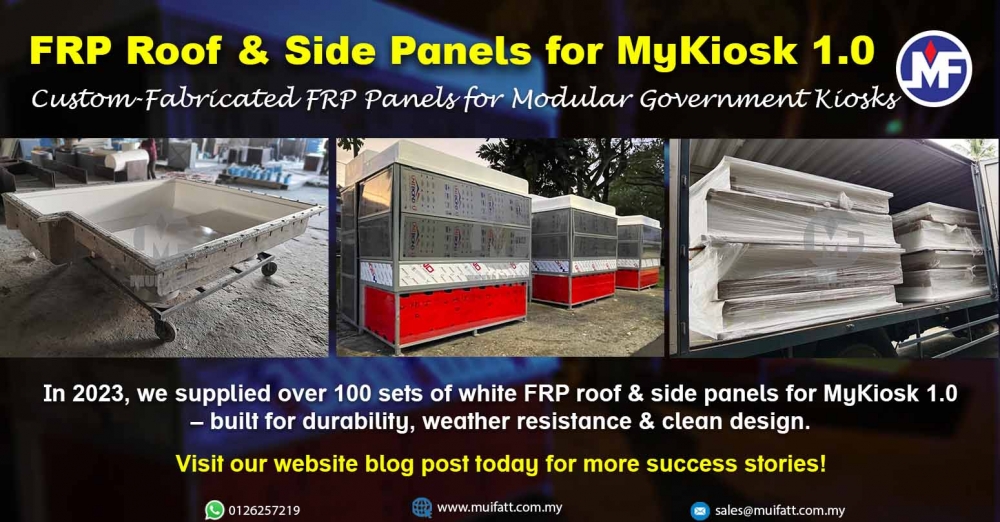

In August 2023, we successfully fabricated and delivered over 100 sets of FRP top roof and side panels to a third-party assembler of MyKiosk structures. These kiosks were distributed to various local district councils across Malaysia, showcasing the versatility and strength of FRP in public infrastructure.

In early 2025, Mui Fatt supplied a range of FRP custom-made seating and planter boxes to Tasek Central Shopping Mall for the newly designed outdoor landscaping at Tuta Courtyard. Fabricated using the hand lay-up method with a textured concrete-look finish, these pieces offer aesthetic appeal and long-term durability for the mall’s public space.

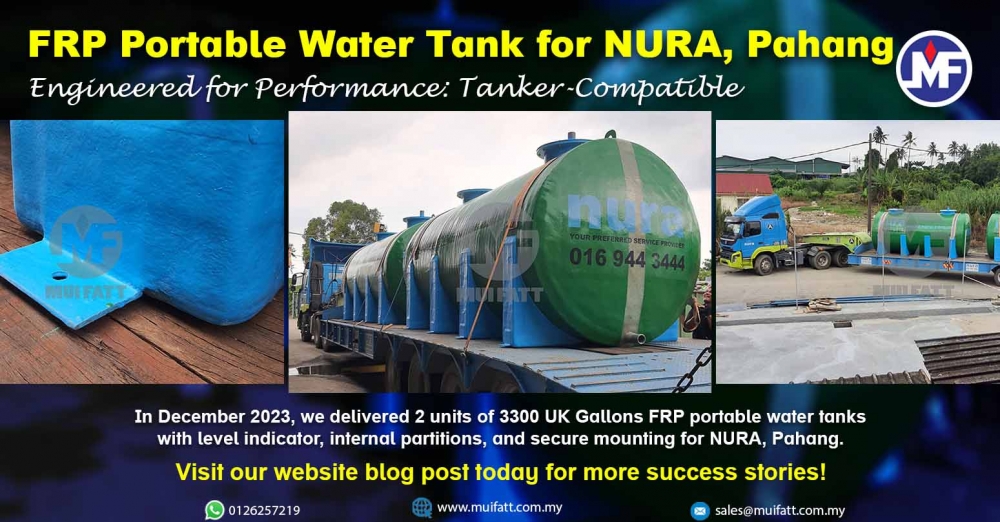

In December 2023, Mui Fatt successfully delivered 2 units of 3300 UK Gallons FRP Portable Water Tanks for NURA. The tanks were manufactured via filament winding, featuring transparent water level indicators, internal partitions, and secure mounts for mobile use. Custom-designed for water tanker compatibility, these units fulfill strict project specifications.

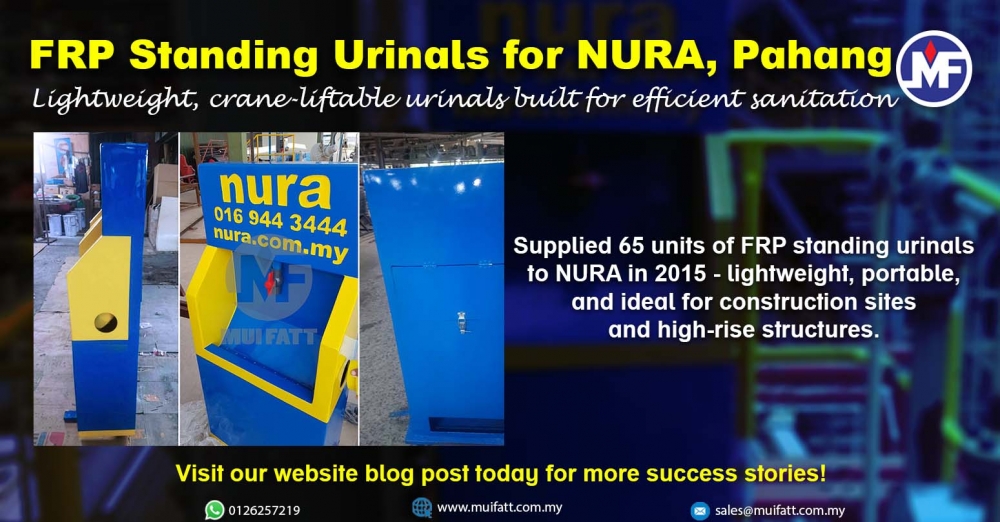

In 2015, Mui Fatt proudly supplied 65 units of FRP high-rise standing urinals to NURA. These units were specifically engineered for temporary construction sites and high-rise structures, providing a hygienic and time-saving sanitation solution for workers. The durable fiberglass construction, combined with portability and cost-efficiency, made it an ideal choice for challenging site conditions.

In 2012, Mui Fatt proudly supplied 50 units of custom-designed FRP kiddie carts for Aeon Shopping Mall. Engineered for durability and child-friendly use, these vibrant red trolleys were modeled after cartoon-themed trains and featured integrated seating for young shoppers. With a sturdy FRP body and steel basket, the carts enhanced both safety and shopping convenience for families—demonstrating how functional design can also bring joy and engagement to retail experiences.

Mui Fatt proudly supplied large quantities of FRP fish trays to a renowned local hypermarket chain in Malaysia. Designed to enhance the presentation and preservation of seafood, our trays offer high durability, ease of cleaning, and compliance with food safety standards—making them an essential asset in modern supermarket seafood sections.

In 2024, Mui Fatt successfully delivered 500 units of custom-made PE logbooms to multiple lakes in Cameron Highlands. These floating barriers were manufactured via roto molding, injected with PU foam for buoyancy, and deployed as visual warnings for restricted or hazardous zones.

Mui Fatt Group is hiring! We’re looking for a Mandarin-speaking Technical Sales Support Specialist to assist with product sales, technical queries, and PRC client communications.

In January 2025, Mui Fatt proudly sponsored three units of PE Water Tanks (Model BM300/350) to Sekolah Menengah Kebangsaan Pulau Indah. These tanks will be installed as part of the school’s rainwater harvesting system to promote water conservation, supporting both the school’s sustainability initiative and Klang’s 2030 low-carbon development goals.

In early 2025, Mui Fatt proudly contributed to the interior landscaping of one of Malaysia’s most prestigious retail destinations — The Exchange TRX Mall. A total of 42 units of FRP planter pots in sleek black and white finishes were supplied to enhance the mall’s visual appeal and greenery integration. The modern, high-gloss fiberglass design complemented the mall’s sophisticated architecture while offering long-lasting durability, low maintenance, and moisture resistance — ideal for bustling indoor commercial spaces.

In October 2020, Majlis Perbandaran Pasir Gudang initiated a project to enhance accessibility and environmental integration in key wetland and lake areas in Johor. Mui Fatt was proud to supply durable, corrosion-resistant FRP pultruded grating and FRP yellow handrails for the construction of elevated mangrove boardwalk walkways at Tasek Perdana, Dahlia, and Sungai Buloh.

In 2015, as part of Malaysia’s effort to expand rural telecommunications, Mui Fatt supplied three sets of FRP customized hand layup camouflage panels for TELCO towers in remote locations. Designed to visually blend with natural surroundings while maintaining full RF transparency, our fiberglass panels provided a sustainable, non-intrusive solution to infrastructure development in ecologically sensitive areas.

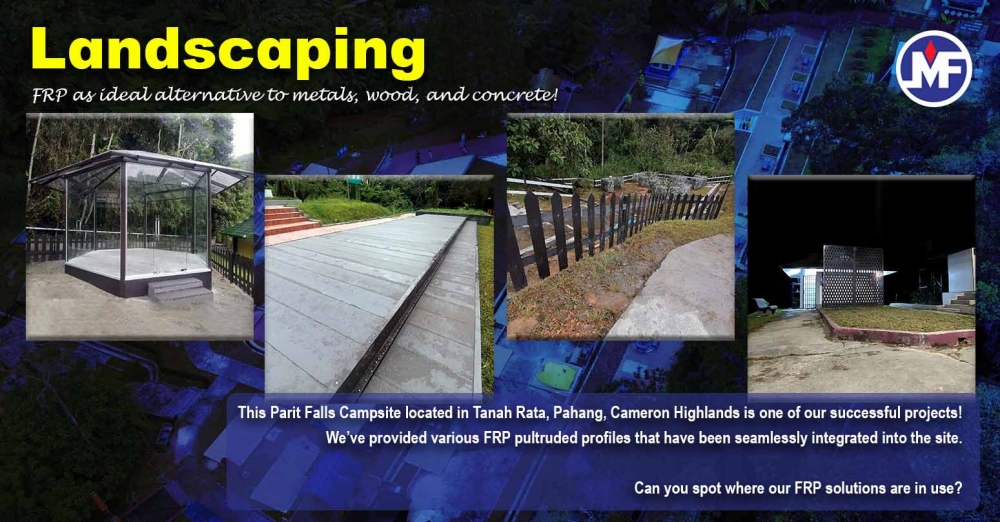

Parit Falls Campsite, a scenic retreat in Tanah Rata, Cameron Highlands, needed robust yet aesthetically pleasing structures that could endure the region’s humid climate. Mui Fatt supplied high-quality FRP pultruded profiles and OEM trellises, which were skillfully assembled into gazebos, fencing, an event deck, and trellises. These structures enhanced the landscape, providing durability, low maintenance, and a modern aesthetic.

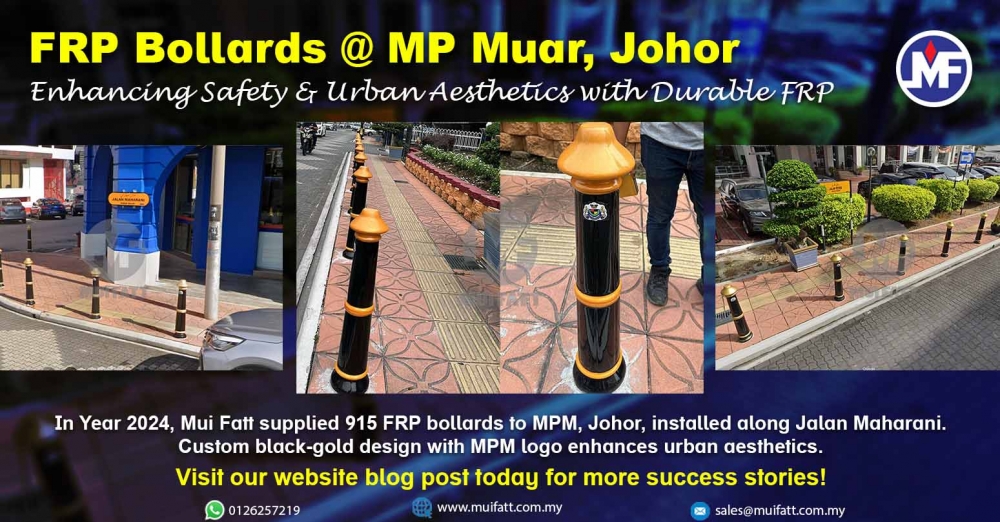

In 2024, Mui Fatt supplied 915 custom FRP bollards to Majlis Perbandaran Muar (MPM), Johor, enhancing urban aesthetics and pedestrian safety along Jalan Maharani and Jalan Petrie. Designed in black and gold with the MPM logo, these durable, corrosion-resistant bollards offer a long-lasting alternative to traditional metal options, reinforcing Muar’s identity as Bandar Diraja.

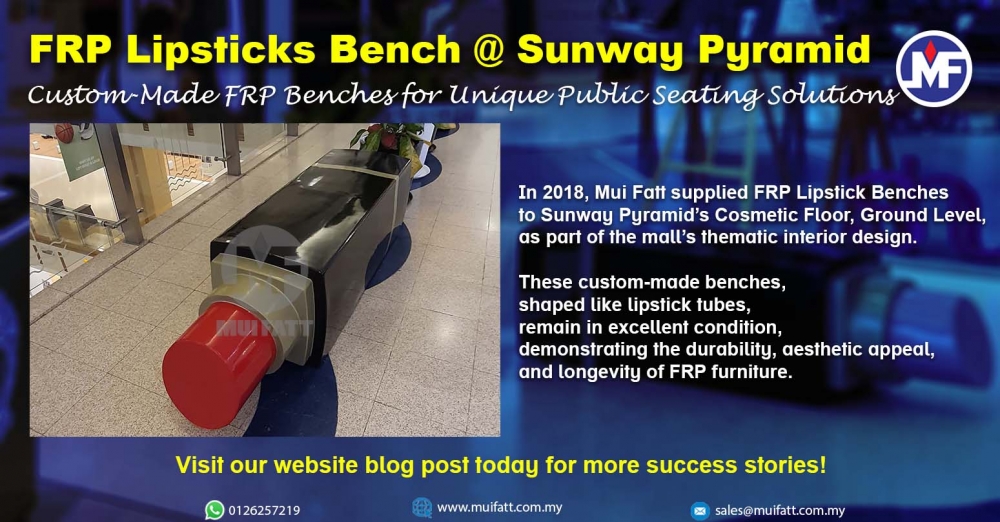

In 2018, Mui Fatt supplied 6-8 FRP Lipstick Benches to Sunway Pyramid’s Cosmetic Floor, Ground Level, as part of the mall’s thematic interior design. These custom-made benches, shaped like lipstick tubes, remain in excellent condition, demonstrating the durability, aesthetic appeal, and longevity of FRP furniture.

In April 2023, we supplied custom-length FRP roofing sheets, including a remarkable 46-ft continuous sheet, for a chemical manufacturing plant in Kuantan. Primarily in Riviera Blue, with translucent sheets for natural lighting, the shipment was delivered in a single trip using a 46-ft flat loader. This project enhanced the facility’s durability, corrosion resistance, and light optimization.

In November 2015, Mui Fatt supplied high-quality FRP planter pots and FRP benches to Vista Alam Serviced Apartment, Shah Alam, enhancing the condominium's common areas with long-lasting and aesthetically pleasing outdoor furniture. The project featured sand-gritted earth-colored and two-tone blue FRP pots in various sizes, along with uniquely designed number-shaped and rectangular FRP benches. These weather-resistant and low-maintenance solutions provided functional and decorative enhancements to the living environment.

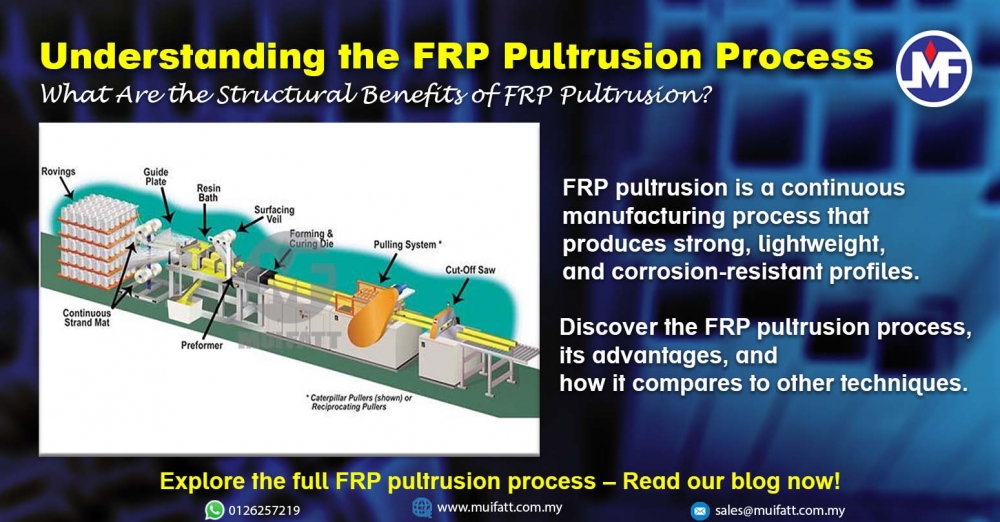

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

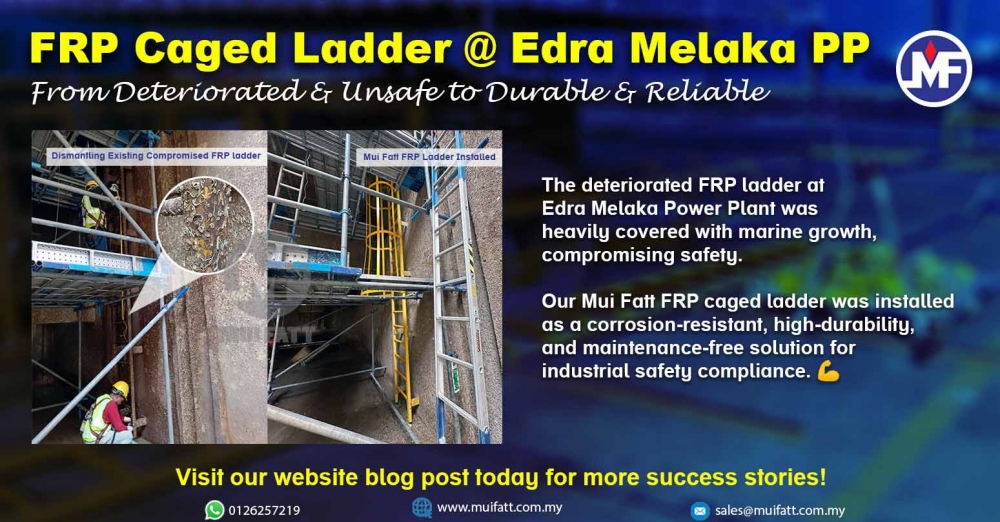

In 2024, we supplied and installed 19 FRP caged ladder units at Edra Melaka Power Plant (EMPP) in Alor Gajah, Melaka. The 6-meter-high ladders were installed in the seawater storage area to replace existing FRP ladders that had accumulated clam attachment byssal threads, which compromised their safety and durability. Our team of 10 workers completed the installation within three weeks, ensuring a seamless transition and an opportunity for skill enhancement.

In 2023, Mui Fatt successfully supplied nearly 1000 FRP planter pots to Majlis Perbandaran Jasin (MPJ), Melaka. These fiberglass planters were delivered in two phases—first, for decorative purposes at MPJ’s office front yard with LED-integrated translucent pots, and second, to enhance various locations throughout the city, including road dividers, roundabouts, and public facilities. Our weather-resistant and long-lasting FRP planter pots contribute to urban beautification while ensuring durability against harsh environmental conditions.

Mui Fatt proudly supplied 49 custom FRP planter pots in gold, black, and white to Sunway Pyramid for the Oasis Opening in November 2024. These stylish and durable planters enhance the indoor landscape with a modern touch while offering long-lasting performance. We appreciate Sunway Pyramid’s continued trust in our FRP products.

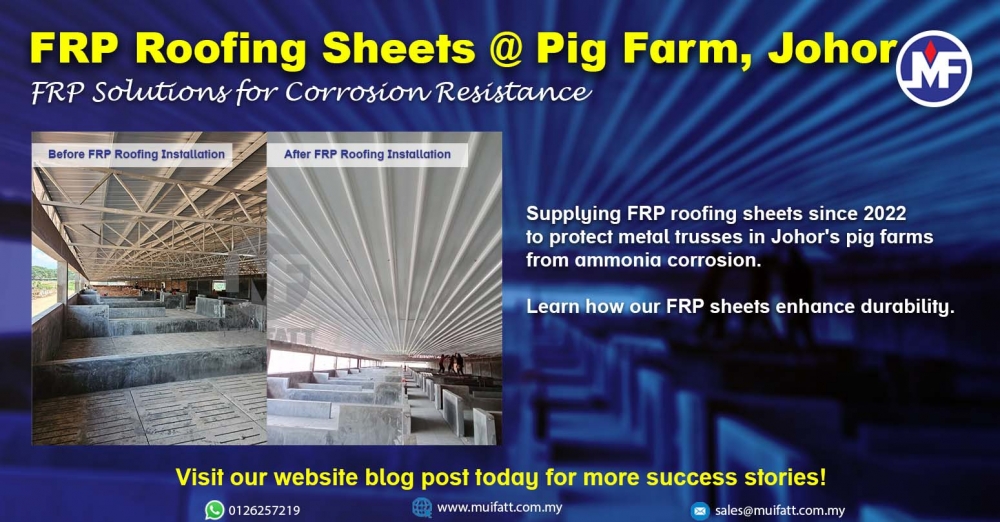

Since 2022, we have been supplying FRP roofing sheets to one of Malaysia’s largest pig farming companies in Johor. Ammonia from pig excrement accelerates metal corrosion, leading to structural damage over time. Our FRP roofing sheets act as a protective shield, preventing direct exposure to metal trusses and ensuring long-term durability. With repeated orders for expansion projects, our solution has proven its effectiveness in harsh farming conditions.

In preparation for the 2010 FIFA World Cup, Sasol refurbished its gas stations across South Africa to enhance the township's image. As part of this large-scale upgrade, we collaborated with Hexagon PCA to manufacture and deliver a few hundred sets of customized FRP products, including FRP litterbins, FRP Speedpoint kiosks, and FRP column cladding. These high-quality, durable FRP solutions met Sasol’s strict specifications and stringent QC requirements, ensuring long-lasting performance in outdoor environments.

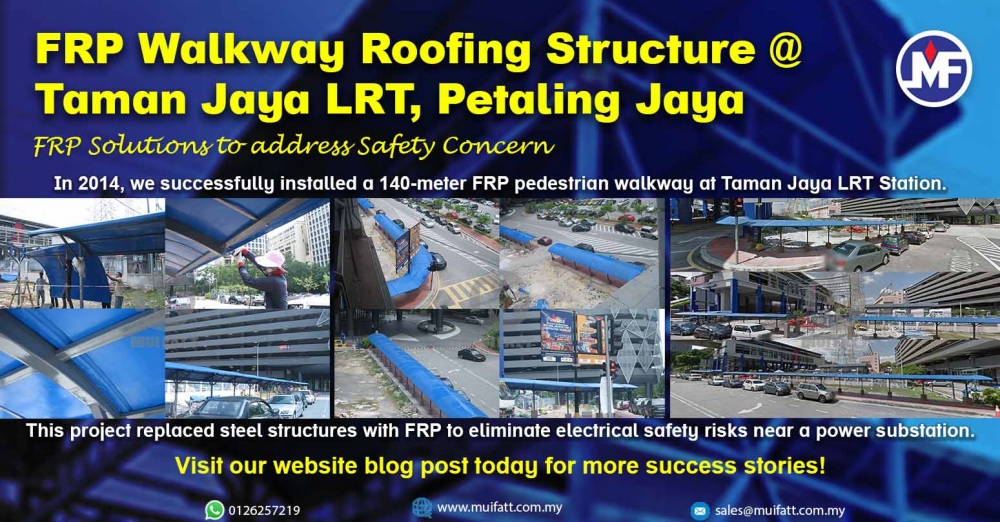

In 2014, we successfully installed a 140-meter FRP pedestrian walkway at Taman Jaya LRT Station. This project replaced steel structures with FRP to eliminate electrical safety risks near a power substation. The walkway ensures long-term durability, low maintenance, and excellent weather resistance. Learn how FRP solutions improve public infrastructure.

Our 33,080 UK gallon FRP closed top tanks, designed with exceptional durability and corrosion resistance, were successfully delivered to Ramly Food Processing’s newly developed factory. These customized tanks ensure efficient water storage to support their large-scale operations, demonstrating our capability to meet specific industrial requirements.

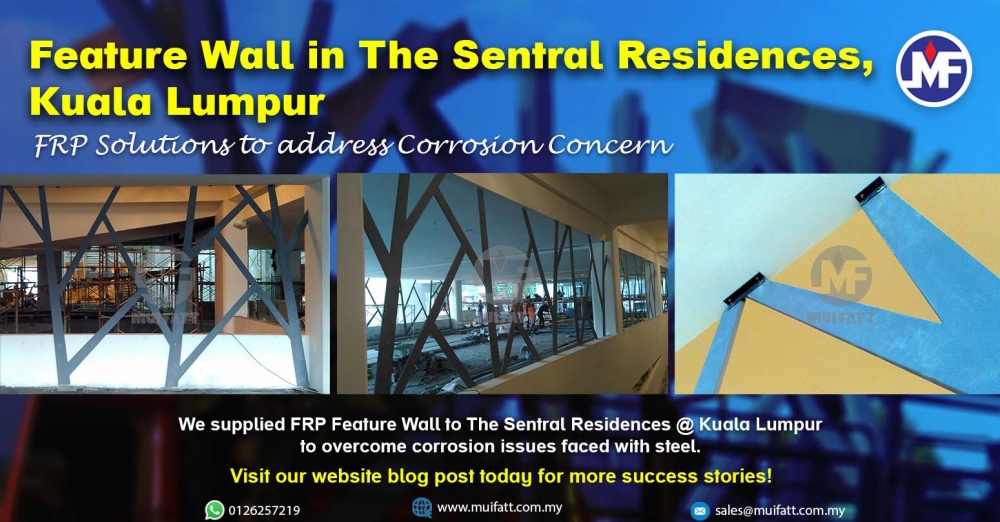

In 2016, Mui Fatt supplied FRP hand-layup flat bars for a featured wall at The Sentral Residences' carpark in KL Sentral, covering 20% of the overall feature wall area. The FRP material was chosen to mitigate corrosion issues, offering long-lasting durability compared to conventional steel. Post-installation, an onsite coating spray was applied to create a seamless finish.

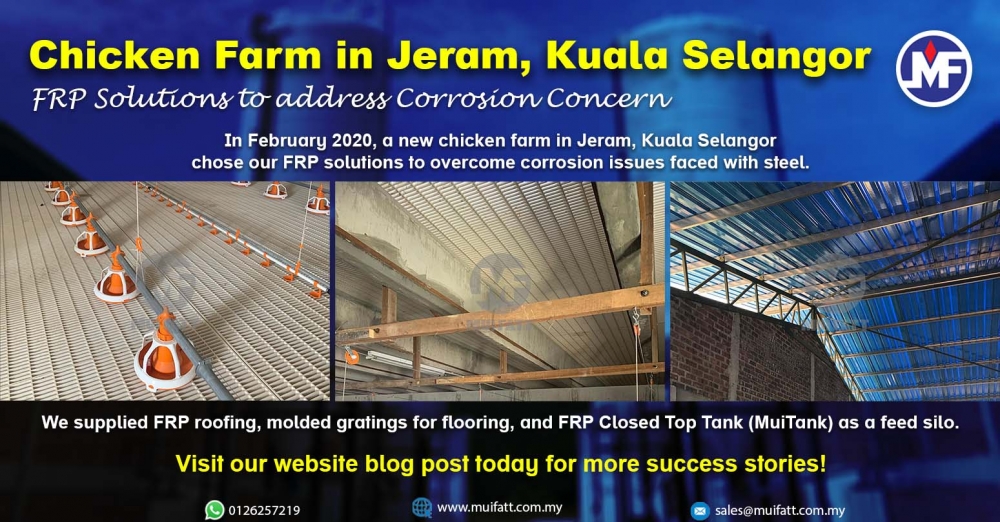

In February 2020, a new chicken farming plant was established in Jeram, Kuala Selangor. Learning from corrosion issues at their existing farms, the customer approached us for FRP solutions as a durable alternative to steel. We supplied FRP roofing, FRP molded gratings for flooring, and 10-meter high FRP Closed Top Tanks (MuiTank) as a feed silo. These FRP solutions offered superior corrosion resistance, ensuring longevity and hygiene for the new setup.

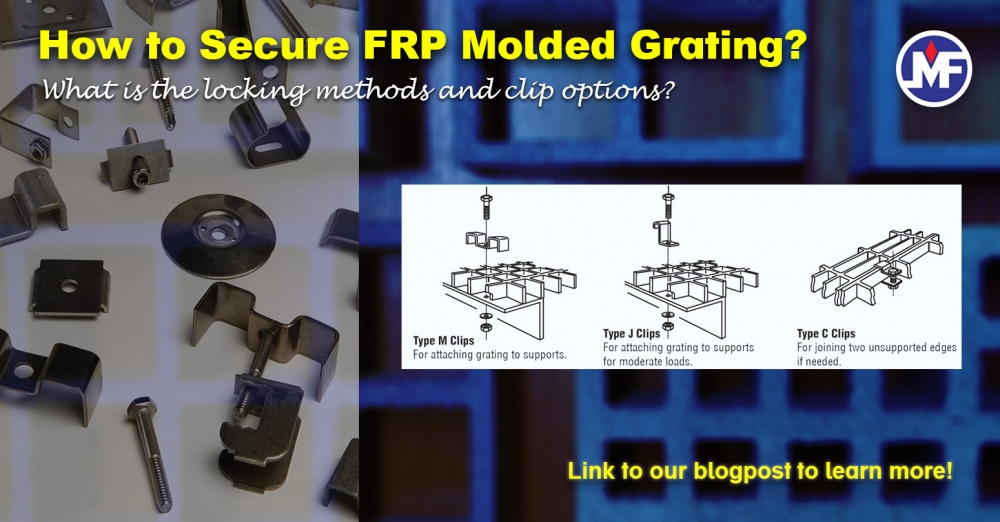

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

Choosing between an individual septic tank with filter media and a mechanical septic tank with an air blower depends on efficiency, cost, and maintenance. This article breaks down their key differences to help you select the right wastewater treatment solution.

Unlike traditional septic systems, mechanical septic tanks use air blowers to accelerate wastewater treatment. This article explores how air blowers enhance aeration, promote bacterial breakdown, and ensure a more effective sewage treatment system in Malaysia.

Filter media plays a critical role in solid-liquid separation and biological treatment in individual septic tanks. This article explores the importance, types, and benefits of filter media in wastewater treatment, helping you make an informed decision when selecting a septic system in Malaysia.

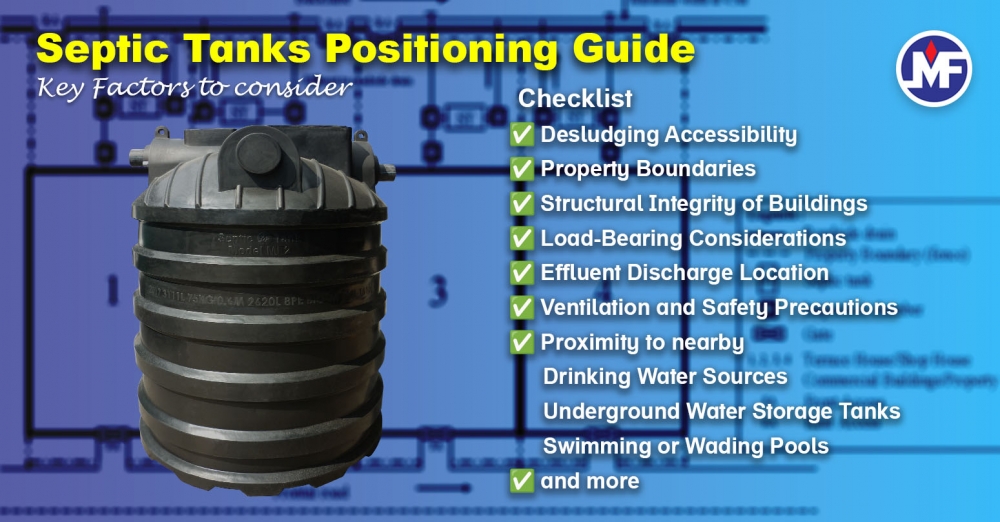

Proper septic tank placement is crucial for efficient wastewater treatment. Learn why septic tanks should not be placed inside a house, how their location impacts wastewater disposal, and how to determine the best site for installation.

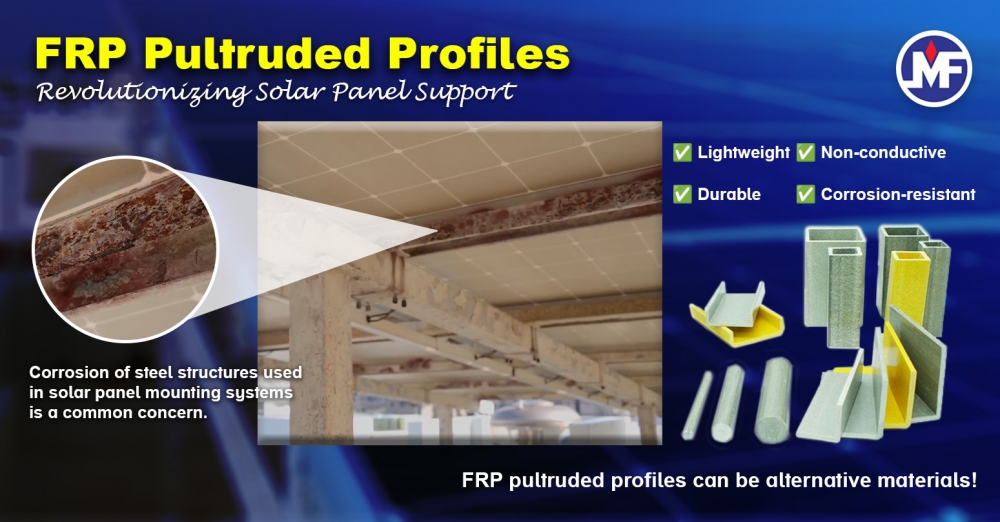

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

Discover the manufacturing marvel of rotomolding! Learn why this process ensures durable planter pots and other polyethylene products with exceptional quality.

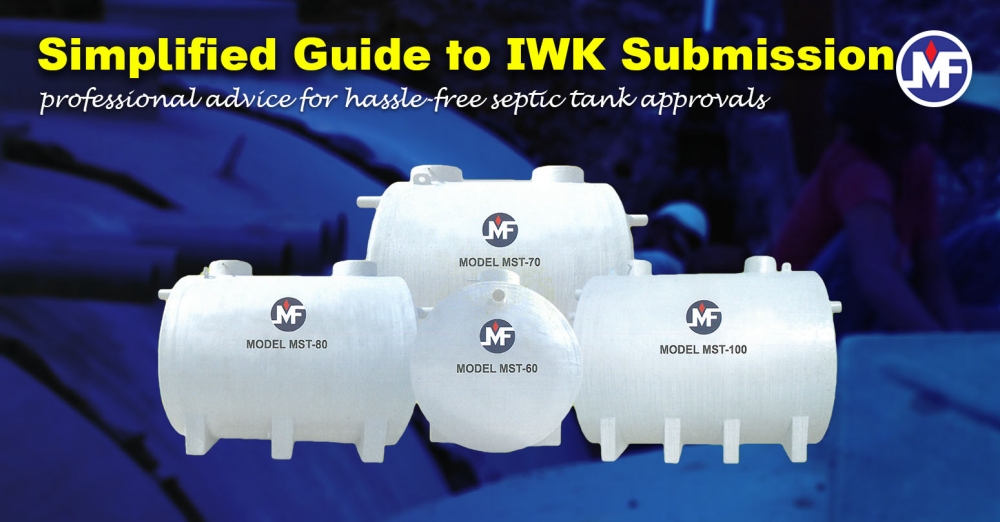

Navigating the IWK submission process can be challenging. Discover our simplified steps and professional advice for hassle-free septic tank approvals.

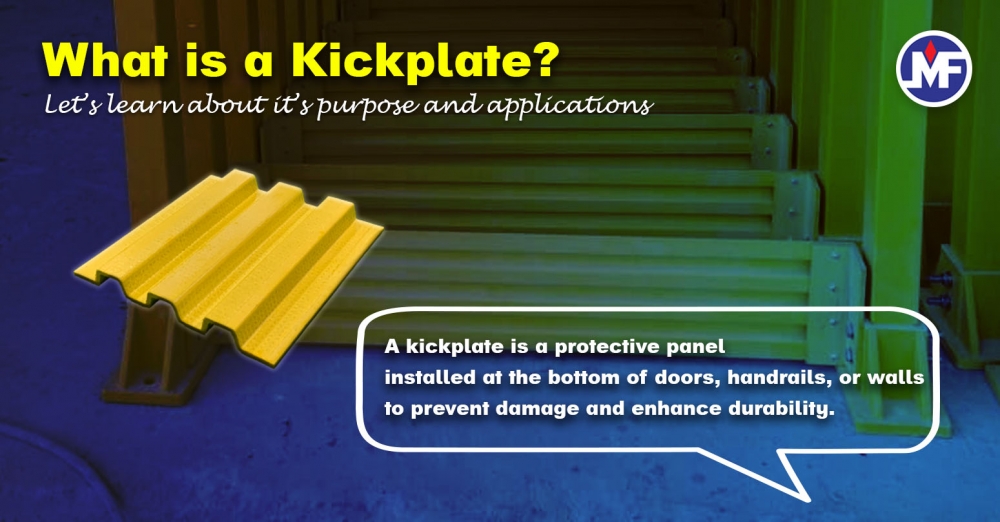

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

Understand the regulations and guidelines for water and septic tanks in Borneo, plus compliance with SPAN, IWK, and SIRIM standards in Malaysia.

Flooding in Malaysia is increasingly common. Explore how plastic flood barriers could be a game-changer.

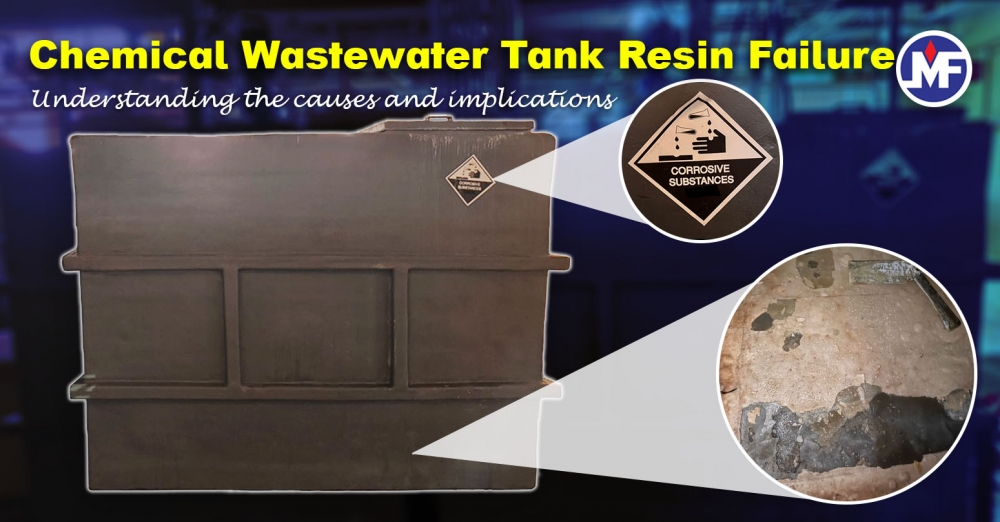

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

Discover what Population Equivalent (PE) is and its importance for septic systems, with an easy-to-follow guide for end-users, potential issues of choosing the wrong capacity, and expert tips from Mui Fatt.

We’re looking for an Admin Clerk/Assistant to support operations at Mui Fatt. Be part of a dynamic and innovative family business!

A step-by-step guide on water tank considerations, including material, size, application, and more. Learn how to pick the perfect tank for your needs.

Understand the recyclability of polyethylene, its minimal environmental impact, and why we prioritize safety in manufacturing eco-friendly PE products.

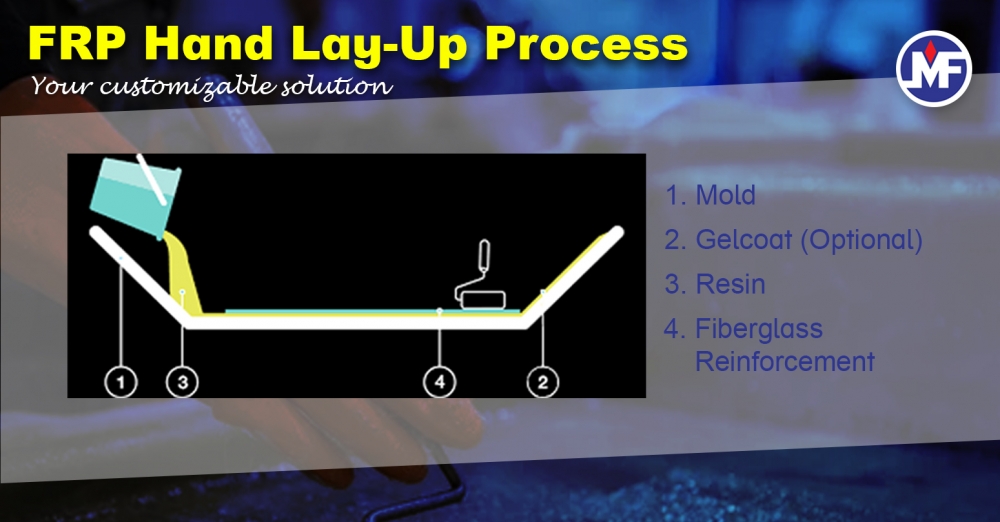

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

Mui Fatt celebrated the remarkable journey of Pak Jono, our factory lead worker, who retired after 33 years. A warm farewell with lunch for the entire team was organized by Mr. and Mrs. Ng.

Learn the differences between recycle and recycling bins, the types of bins by color and material, and why they're essential for waste management in Malaysia. Discover our FRP and PE recycle bins for your needs.

This article explores biodegradable septic tanks, covering their materials, operations, costs, and maintenance. It also explains why they're rare in Malaysia and introduces alternative sustainable options.

Explore the significance of yearly renewals of SIRIM, SPAN, and ISO certifications at Mui Fatt Group and how it maintains quality and compliance for IKRAM-listed products.

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.

Explore the regulations governing fire tanks in Malaysia, the materials approved for use, and the differences between fire tanks, reservoir tanks, and suction tanks.

Regular septic tank desludging ensures efficiency, prevents costly repairs, and protects your environment. Learn the top 10 reasons why this process is critical every two years.

Mui Fatt Marketing Sdn Bhd secures the prestigious Platinum Award at the 6th Lang International Corporate Titan Awards, underscoring our commitment to excellence, innovation, and sustainable industry solutions in Malaysia.

In this blog, we explore why using SPAN-approved water and septic tanks is critical for compliance, safety, and reliability in construction projects across Malaysia. Learn how SPAN certification ensures the quality of your tanks, and why it’s essential for maintaining water service standards under Act 655. Discover how various end-user products such as water tanks and septic tanks adhere to this legislation and the consequences of non-compliance, emphasizing the importance of strict adherence for safeguarding Malaysia's water resources and public well-being.

Explore the differences between FRP cable ladders and trays, why FRP is essential, and how to choose the right system for your installation.

Explore Mui Fatt's SIRIM-certified and IKRAM SBBT-listed products: quality, compliance, and local manufacturing for your construction projects.

Learn about the importance of SIRIM certification and how our certified FRP molded gratings enhance safety and performance across various industrial applications.

Discover the process, benefits, and sustainability of FRP lamination. This article covers everything from application steps to industry-specific insights and FAQs.

Explores the role of fiberglass aircraft warning spheres in enhancing aviation safety across Malaysia's rapidly developing urban landscape.

Explore how Fiberglass-Reinforced Plastic (FRP) is transforming wastewater treatment globally with its superior corrosion resistance, durability, and cost-effectiveness, ensuring long-term sustainability and efficient water management.

Explore the advantages of upgrading to Mui Fatt Marketing's FRP composite level indicator for your water tank. Learn about its durability, easy installation, and customization options.

Discover how fiberglass solutions provide a sustainable and cost-effective method for odor control in Malaysian wastewater treatment plants, ensuring long-term operational efficiency and environmental stewardship.

Discover why individual septic tanks are an ideal solution for new housing developments in areas underserved by the Langat Centralized Sewage Treatment Plant. Learn about their benefits, installation process, and environmental impact.

Data centers require robust and efficient cooling systems to maintain optimal performance. Fiberglass-Reinforced Plastic (FRP) panel water tanks play a crucial role in these systems by providing durable and efficient water storage solutions. This article explores the benefits of FRP panel water tanks, their importance in data center cooling, and addresses frequently asked questions.

Explore the wonders of wetlands and learn about the importance of conservation efforts. Discover how Mui Fatt specializes in manufacturing high-quality FRP solutions tailored for wetland infrastructure, ensuring durability, sustainability, and lasting protection for these vital ecosystems.

Explore the transformative impact of Fiberglass-Reinforced Plastic (FRP) technology in wastewater treatment plants. Discover how FRP has revolutionized plant infrastructure, addressing challenges such as corrosion and rising material costs. Learn why FRP is the material of choice for sustainable, cost-effective, and efficient water management solutions. Dive into future potential to understand why FRP is shaping the future of wastewater treatment.

Discover the step-by-step process of acquiring high-quality FRP panel tanks with this comprehensive guide. Learn how to assess your requirements, research suppliers, customize your tank, and more. Trust us for expert advice and reliable FRP solutions.

Floating solar panels are like regular solar panels, but they float on water instead of being on land. They're installed on lakes, ponds, or reservoirs. They work by capturing sunlight and turning it into electricity. They're good because they save space, help reduce water evaporation, and can even improve water quality.

Explore the pros and cons of FRP Handlay, SMC, and Pressed Steel Panel Tanks in this comprehensive comparison guide. From durability to maintenance requirements, discover which tank type suits your industrial or commercial needs best!

Wastewater treatment plants are crucial for public health and environmental preservation in Malaysia. However, corrosion poses a significant threat to these facilities, compromising their effectiveness and longevity. This article delves into the corrosion issues facing Malaysian wastewater treatment plants and examines how fiberglass solutions are revolutionizing infrastructure to combat these challenges.

Discover the evolving debate between fiberglass and steel in Malaysia's construction landscape. Amidst the country's challenging climate conditions, understanding the pros and cons of each material is crucial for informed decision-making. Let's delve into the merits and limitations of fiberglass as an alternative to steel, examining its suitability for various applications.

Discover how integrating fiberglass products from Muifatt can revolutionize solar panel maintenance and sustainability in Malaysia. Explore the advantages of fiberglass grating and pultrusion profiles over conventional steel support structures for solar energy projects. Learn how renewable energy initiatives like the Tan Chong Group's floating solar power plant in Serendah are driving the transition towards a greener future.

Discover the ultimate guide to OSHA compliant fixed ladder, cat ladder. Enhance safety, customize options, and ensure compliance with our expert solutions. #fixedladder #catladder

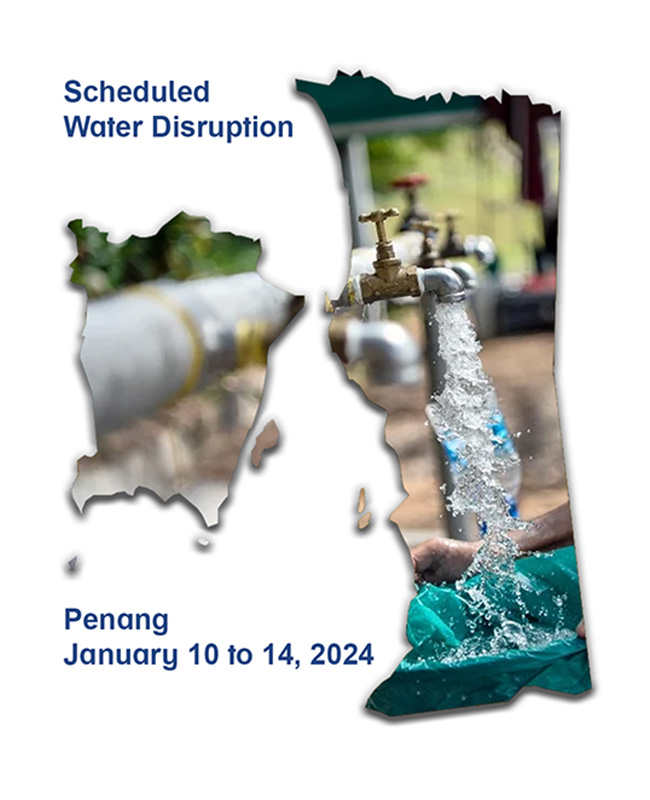

Get essential tips for preparing and staying resilient during scheduled water disruption in Penang. Don't miss out, read more now! #waterdisruptionpenang

Learn how the robust construction of brass and corrosion-resistant properties of copper make these valves ideal for PE water tanks. Discover the benefits, applications, and maintenance tips for ensuring optimal performance in industrial, agricultural, and other settings.

Discover the MyKiosk initiative's mission to provide secure and comfortable business spaces for entrepreneurs in Malaysia. Learn about the benefits of Fiber-Reinforced Plastic (FRP) panels and how they enhance MyKiosk construction. Join us in building a brighter future for small businesses!

Sertai usaha untuk menjadikan Klang lebih bersih! Ketahui inisiatif pengutipan sampah rumah ke rumah/lot ke lot MPK dan spesifikasi tong sampah beroda yang ditetapkan oleh MPK untuk rumah kampung dan perniagaan. Bertindak segera untuk menjaga keindahan Klang!

Discover our advanced UPR protective coatings, expertly designed to safeguard architectural structures and preserve color pigments. Explore the application process, benefits of reinforcement, various UPR types, and other methods for maintaining vibrant colors in architectural designs.

Discover the perfect fish display table for your kitchen or seafood market. Our FRP tables offer optimal storage and an attractive presentation.

Discover the ultimate rooftop walkway solution with our safety-focused, modular and easy-to-use system. Enhance your roof access today!

Discover the step-by-step process of manufacturing concrete manhole cover. Learn the tips for creating high-quality manhole cover with FRP concrete mold!

Upgrade your construction site with durable and high-quality trench covers for utmost safety. Stand out with our top-notch products.

Produk Fiberglass Terbaik di Malaysia: Harga & Jenis Terbaru" can be optimized as: "Produk Fiberglass Terbaru di Malaysia: Harga Murah!

Kegunaan Fiberglass yang Perlu Anda Ketahui: Panduan Lengkap

Pelbagai Jenis Resin: Panduan Terperinci Mengenai Varieti Resin

Discover the reasons why FRP sculptures are widely used in swimming pools and water theme parks. Learn about the benefits they offer, common challenges faced, and how our expertise as a manufacturer can address them. Find out more!

Is Fiberglass Plastic? Fakta Perbezaan dan Kelebihannya

Fiberglass Cloth dan Resin: Panduan Mudah untuk Pemula

Fiberglass Properties PDF: Ciri dan Prestasi Serat Kaca

Discover the components, working principles, and lifespan of cooling towers in this comprehensive guide. Learn about the construction, materials, and benefits of FRP cooling towers. Find insights on water-cooled chiller plants and the importance of make-up tanks. Ensure efficient operation and maximize the lifespan of your cooling tower.

Sifat Kimia Serat Kaca: Fakta Penting yang Wajib Diketahui

Sifat Terkini Kain Fiberglass: Tumpuan pada Ciri-ciri Utama

Discover the world if industrial design, where creativity meets functionality. Learn how industrial designers shape the form and usability of products across industries. Explore the process, trends, and importance of industrial design in creating innovative and user-centered solutions.

Are you a creative problem solver with a passion for design? We're looking for an exceptional Industrial Designer to join our team!

Bahaya Serat Kaca: Kenali Risiko dan Cara Melindungi Diri" can be optimized to: "Is Fiberglass Dangerous? Kenali Risiko dan Lindungi Diri

Fiberglass Manufacturing: Top Suppliers & Fabrication Companies

Fiberglass Manufacturing: Top Suppliers & Fabrication Companies

Have you ever wondered how the products we use every day are made? One of the materials that play a crucial role in many industries is fiberglass. It's a composite material made from glass fibers and resin, which is used to create various products such as tanks, pipes, panels, and more. The process of manufacturing fiberglass requires advanced technology and expertise.

Fiberglass manufacturers produce FRP (Fiber Reinforced Polymer) products that are used in different industries like construction, automotive, aerospace, marine, and more. These products have unique properties that make them suitable for specific applications. For instance, fiberglass tanks are corrosion-resistant and can withstand harsh environments.

The manufacturing process of fiberglass involves several steps that require precision and attention to detail. First, raw materials like glass fibers and resin are mixed together to form a matrix. Then the matrix is molded into the desired shape using molds or other techniques.

Fiberglass manufacturers use advanced technology like computer-aided design (CAD) software to create high-quality products with precise measurements. They also conduct rigorous testing procedures to ensure that their products meet industry standards for strength, durability, and safety.

It all started back in 1932 when Owens Corning invented this revolutionary material. Since then, there has been significant progress in the field of fiberglass manufacturing technology.

Importance of Choosing a Reliable Fiberglass Manufacturer

Why Choose High-Quality Fiberglass Products?

Fiberglass is a popular material used in various industries, including construction, automotive, and marine. It is known for its strength, durability, and flexibility.Quality should be the top priority.

High-quality fiberglass products are essential for ensuring longevity and durability. They can withstand harsh weather conditions and resist wear and tear. Low-quality fiberglass materials may result in costly repairs or replacements down the line.

For example, when choosing a fiberglass pool for your backyard, you want to ensure that it will last for years without needing significant repairs or maintenance. A reliable fiberglass manufacturer will provide high-quality materials that can withstand extreme temperatures and chemical exposure.

Consistent Quality from a Reliable Manufacturer

Choosing a reliable fiberglass manufacturer guarantees consistent quality in every product they offer. These manufacturers use advanced technologies to produce high-quality materials consistently.

A reliable manufacturer follows strict quality control procedures throughout the production process to ensure that each product meets specific standards. This consistency ensures that every customer receives the same level of quality regardless of their location or order size.

When selecting a fiberglass manufacturer, look for one with an established reputation for producing high-quality materials consistently over time. Check reviews online to see what other customers have experienced with their products.

Reduced Risk of Costly Repairs and Replacements

Using quality fiberglass materials reduces the risk of costly repairs and replacements down the line. High-quality products are less likely to break or fail prematurely than low-quality ones.

When using low-quality fiberglass materials in construction projects such as roofing or insulation, there is a higher risk of leaks or mold growth due to poor installation practices or inferior materials used by unscrupulous contractors.

By choosing reputable manufacturers who use only high-grade raw materials in their production process, you can reduce these risks significantly.

When to Use Fiberglass Mat or Cloth?

Fiberglass mat and cloth are two types of materials used in fiberglass manufacturing. They serve different purposes, depending on the project's specific requirements.

Fiberglass mat is a non-woven material made from chopped glass fibers held together with a binder. It is commonly used in construction projects such as roofing or insulation due to its excellent thermal and acoustic properties.

Fiberglass cloth, on the other hand, is a woven material made from continuous glass fibers. It is commonly used in marine applications such as boat building or repair due to its high strength and durability.

When deciding whether to use fiberglass mat or cloth, consider the project's specific requirements. If you need a material that can provide thermal insulation or soundproofing, fiberglass mat may be the best choice. If you need a material that can withstand extreme conditions and resist wear and tear, fiberglass cloth may be more suitable.

Fiberglass Manufacturers and Suppliers in Selangor, Malaysia

If you're looking for high-quality fiberglass products, Selangor, Malaysia is the place to be. This region is home to several reputable fiberglass manufacturers and suppliers that offer a wide range of products for various industries.

Fiberglass Fabrication

One of the most popular uses of fiberglass materials is in fabrication. Fiberglass fabricators use composite materials to create a variety of products such as tanks, pipes, ducts, and other custom-made pieces. There are many reputable fiberglass fabricators in Selangor that can provide you with high-quality custom-made fiberglass products.

One such manufacturer is FIBERFLON® Malaysia Sdn Bhd. This company specializes in the production of PTFE-coated glass fabrics which are highly resistant to chemicals and extreme temperatures. They also manufacture PTFE-coated conveyor belts used in manufacturing processes.

Another well-known manufacturer is G&P Fiber Glass Sdn Bhd which produces a wide range of fiberglass-reinforced plastic (FRP) products for industrial applications such as water treatment plants, chemical storage tanks, and cooling towers.

Fiberglass Furniture

Fiberglass furniture has become increasingly popular due to its durability and stylish designs. Many furniture manufacturers in Selangor specialize in producing high-quality fiberglass furniture that can withstand harsh weather conditions while maintaining its aesthetic appeal.

One such manufacturer is DZIGNO Sdn Bhd which produces an extensive range of outdoor furniture made from durable materials including aluminum frames coated with powder paint finishes combined with woven synthetic rattan fibers or teak wood accents.

Another manufacturer worth mentioning is Kian Contract Sdn Bhd which specializes in producing commercial-grade furniture for hotels and resorts using high-quality materials like solid surface tops combined with molded FRP bases creating unique yet functional designs.

Fiberglass Materials

Fiberglass materials are widely used in various industries such as automotive, construction, and marine. The quality of these materials is essential to ensure the durability and reliability of the products produced.

One of the leading manufacturers of fiberglass materials in Selangor is AGC Asia Pacific Pte Ltd which produces high-quality glass fibers for use in composites manufacturing. They also manufacture specialty fiberglass products such as chopped strands, rovings, and mats.

Another reputable supplier is Nippon Electric Glass (NEG) Malaysia Sdn Bhd which produces a wide range of fiberglass products including E-glass yarns, ECR glass fiber mats, and Cem-FIL® alkali-resistant fiberglass reinforcing mesh for concrete reinforcement.

Top Fiberglass Manufacturers and Suppliers in the USA

Owens Corning: Global Leader in Fiberglass Production

Owens Corning is a global leader in fiberglass production with a strong presence in the USA. The company produces a wide range of fiberglass products for various industries including construction, transportation, and industrial markets. Owens Corning offers high-quality insulation solutions that are energy-efficient and sustainable. The company's insulation products help reduce energy consumption, lower greenhouse gas emissions, and improve indoor air quality.

In addition to insulation products, Owens Corning also produces roofing shingles, composites, and other building materials. The company has been recognized for its commitment to sustainability and has received numerous awards for its environmental initiatives. Owens Corning is committed to reducing waste, conserving resources, and protecting the environment.

PPG Industries: Wide Range of Fiberglass Products for Various Industries

PPG Industries is another leading manufacturer of fiberglass products in the USA. The company offers a wide range of fiberglass products for various industries including automotive, construction, marine, and aerospace. PPG's fiberglass products are known for their strength, durability, and resistance to corrosion.

The company's automotive fiberglass products include body panels, hoods, fenders, spoilers, and other components used in racing cars. In the construction industry, PPG's fiberglass products are used in roofing systems as well as wall panels and facades. In the marine industry, PPG's fiberglass products are used in boat hulls as well as decks and superstructures.

PPG Industries is committed to innovation and invests heavily in research and development to create new technologies that improve product performance while reducing environmental impact.

Jushi Group: One of the Largest Fiberglass Manufacturers in the World

Jushi Group is one of the largest manufacturers of fiberglass in the world with a production capacity of over 2 million tons per year. The Chinese-based company has operations around the globe, including in the USA. Jushi Group produces a wide range of fiberglass products for various industries including construction, transportation, and wind energy.

The company's fiberglass products are known for their high strength-to-weight ratio, excellent corrosion resistance, and thermal insulation properties. Jushi Group's products are used in wind turbine blades, automotive components, and building materials.

Jushi Group is committed to sustainability and has implemented numerous initiatives to reduce its environmental impact. The company has invested heavily in renewable energy sources such as solar and wind power to reduce its reliance on fossil fuels.

OCM Enterprise as a Fiberglass Manufacturer and Supplier

Custom Fiberglass Products

OCM Enterprise is a leading custom fiberglass manufacturer and supplier. They specialize in producing composite products made from fiberglass and carbon fiber, which are used in various industries such as oil and gas, automotive, construction, marine, and many more. The company has a team of experienced professionals who can design custom fiberglass products according to customers' specific needs.

OCM's custom fiberglass products are designed to withstand harsh environments and conditions. They can be used for applications that require high strength-to-weight ratio, corrosion resistance, fire resistance, electrical insulation properties, and durability. Some examples of OCM's custom fiberglass products include tanks, pipes, ducts, housings, enclosures, grating systems, panels, covers, and many more.

Competitive Cost

One of the advantages of choosing OCM Enterprise as your fiberglass manufacturer is their competitive cost. They offer affordable prices without compromising on quality or performance. Their production line is optimized for efficiency to reduce manufacturing costs while maintaining high-quality standards.

OCM's pricing strategy is transparent and fair. They provide detailed quotes with no hidden fees or charges upfront. Customers can choose from different pricing models based on their requirements such as volume discounts or project-based pricing.

In-House Production Line

Another advantage of working with OCM Enterprise is their in-house production line. They have complete control over the manufacturing process from start to finish. This allows them to ensure consistent quality standards throughout the production cycle.

OCM's state-of-the-art facilities enable them to produce large quantities of custom fiberglass products efficiently without compromising on quality or lead times. Their production line includes advanced equipment such as CNC machines for precision cutting and shaping of composite materials.

Serving Various Industries

OCM Enterprise serves various industries that require high-performance composite materials such as oil and gas exploration companies that need durable pipe systems for offshore drilling operations; automotive manufacturers that require lightweight and strong components for their vehicles; and construction companies that need corrosion-resistant products for infrastructure projects.

Their experience in serving different industries has allowed them to develop expertise in designing custom fiberglass products that meet specific industry requirements. They work closely with customers to understand their needs and provide solutions that are tailored to their unique applications.

Company Summaries: Top Featured Fiberglass Manufacturers and Suppliers on Thomas

Thomas Features Top Fiberglass Manufacturers and Suppliers

It can be difficult to know where to start. Fortunately, Thomas offers a comprehensive list of top fiberglass companies that make it easy for customers to find what they need. With over 120 years of experience connecting buyers and suppliers, Thomas is a trusted resource in the manufacturing industry.

Thomas' Table Provides a Comprehensive List of Fiberglass Companies

One of the standout features of Thomas' fiberglass manufacturers list is its table format. The table provides an at-a-glance view of each company's location, website, and product offerings. Customers can easily sort the table by any column to compare companies based on their specific needs. Whether you're looking for a supplier close to home or a company that specializes in a particular type of fiberglass product, Thomas' table has you covered.

These Featured Companies Offer a Range of Fiberglass Products

From insulation to composites, fiberglass is used in a wide variety of applications across many industries. That's why it's important to choose a manufacturer or supplier that offers the products you need. The companies featured on Thomas' list offer everything from raw materials like fiberglass cloth and roving to finished products like pipes, tanks, and panels.

In addition to traditional uses like insulation and construction materials, some manufacturers on the list specialize in niche areas like marine-grade fiberglass for boats or high-temperature-resistant materials for industrial applications.

Thomas' List Includes Both Large and Small Fiberglass Manufacturers

No matter what size your business is or how much fiberglass you need, there are options on Thomas' list that can meet your requirements. Some companies are large-scale manufacturers with multiple locations across the country or even around the world. Others are smaller operations that specialize in custom orders or unique products.

One advantage of working with smaller manufacturers is the ability to get personalized attention and tailored solutions. On the other hand, larger companies may offer more resources and faster turnaround times. With Thomas' list, customers can compare and contrast different manufacturers to find the right fit for their needs.

Customers Can Easily Compare and Choose from the Top Fiberglass Suppliers on Thomas

In addition to its user-friendly table format, Thomas offers a wealth of information about each featured fiberglass manufacturer. Customers can click through to each company's profile page to learn more about their history, capabilities, certifications, and more. Some profiles even include customer reviews or case studies that provide additional insight into a company's strengths and weaknesses.

By using Thomas' list of top fiberglass manufacturers and suppliers, customers can save time and hassle in their search for high-quality products. With so many options available in one place, it's easy to compare prices, features, and services to make an informed decision. Whether you're a small business owner or a purchasing manager at a large corporation, Thomas has everything you need to find the right fiberglass supplier for your needs.

Capabilities of Fiberglass Fabrication Companies and Suppliers

What is fiberglass fabrication, and how is it performed?

Fiberglass fabrication is a process that involves the creation of fiberglass products through the use of raw materials such as filaments and glass fibers. The process typically begins with the selection of appropriate raw materials based on the desired product specifications. The selected materials are then processed using various techniques such as weaving, knitting, or braiding to create a fabric-like material.

Once the fiberglass fabric has been created, it can be molded into different shapes using techniques such as compression molding or resin transfer molding. These molding techniques involve applying heat and pressure to the fiberglass fabric while it is in a mold to create a final product with the desired shape.

Services offered by fiberglass fabrication companies

Fiberglass fabrication companies offer a wide range of services for various industries, including aerospace, construction, and furniture. These companies specialize in creating custom-made products based on specific customer requirements. Some common services offered by these companies include:

-

Design and engineering: Fiberglass fabrication companies work closely with customers to understand their needs and develop customized solutions that meet their requirements.

-

Prototyping: Before creating a final product, fiberglass fabrication companies may create prototypes to test functionality and ensure that all specifications are met.

-

Manufacturing: Once the design has been finalized, fiberglass fabrication companies manufacture products using various techniques such as compression molding or resin transfer molding.

-

Finishing: After manufacturing, products may undergo finishing processes such as sanding or painting to improve their appearance.

Role of suppliers in the industry

Suppliers play an essential role in the fiberglass industry by providing raw materials such as filaments and glass fibers to manufacturers. These suppliers source high-quality raw materials from around the world and provide them to manufacturers at competitive prices.

In addition to providing raw materials, some suppliers also offer value-added services such as technical support or training for manufacturers. This helps ensure that manufacturers are using the raw materials correctly and can produce high-quality products.

Applications of fiberglass materials

Fiberglass materials have a wide range of applications across various industries. One popular application is in the furniture industry, where fiberglass is used to create chairs, tables, and other pieces of furniture. Fiberglass furniture is popular due to its strength and durability, making it an ideal material for outdoor use.

In addition to furniture, fiberglass materials are also commonly used in the aerospace industry. Fiberglass composites are lightweight yet strong, making them ideal for use in aircraft components such as wings or fuselages. The construction industry also uses fiberglass materials for applications such as insulation or roofing.

Importance of distribution firms

Distribution firms play a crucial role in the fiberglass industry by providing efficient transportation and logistics services for fiberglass products. These firms ensure that products are delivered on time and in good condition, which is essential given the fragile nature of many fiberglass products.

In addition to transportation services, distribution firms may also offer value-added services such as inventory management or order tracking. This helps ensure that customers receive their orders quickly and efficiently while minimizing any potential disruptions to their operations.

Top Fiberglass Suppliers in the USA that Qualify for Diversity Status

Fiberglass is a popular material used in various industries, including construction, automotive, and aerospace. The United States is home to several fiberglass manufacturers that offer high-quality products and services. However, not all of these suppliers qualify for diversity status, which is essential for businesses that want to work with government agencies.

What is Diversity Status?

Diversity status refers to the certification program offered by the Small Business Administration (SBA) for businesses owned by minorities, women, veterans, and other disadvantaged groups. This program aims to promote equal opportunities for small businesses in federal contracting. Companies with diversity status can access a wide range of benefits and opportunities such as mentorship programs, training workshops, and government contracts set aside specifically for diverse businesses.

Top Fiberglass Suppliers That Qualify for Diversity Status

-

Strongwell - Founded in 1956 and headquartered in Virginia, Strongwell is a leading manufacturer of pultruded fiberglass products such as structural shapes, grating systems, handrails, and decking materials. The company has over 650 employees across nine locations worldwide and holds certifications from various organizations such as ISO 9001:2015 and AS9100D.

-

Enduro Composites - Established in 1954 and based in Texas, Enduro Composites specializes in manufacturing corrosion-resistant fiberglass products such as cable trays, trench covers, enclosures, tanks & vessels. The company has over 350 employees across four locations globally and serves clients from different industries such as oil & gas refineries.

-

Fiberglass Coatings Inc - Based out of Florida since its inception in 1979,Fiberglass Coatings Inc specializes on composite materials ranging from reinforcements like fabrics,mats etc to resins,epoxies,gelcoats etc. The company has over 50 employees and serves clients from different industries such as marine, aviation, and automotive.

Top Fiberglass Suppliers in the USA: Minority-Owned Businesses

Fiberglass suppliers in the USA are not limited to large corporations.

When people think of fiberglass manufacturers, they often think of large corporations with massive production facilities. However, that is not always the case. There are many smaller businesses owned by minorities that also play a significant role in the fiberglass industry. These businesses offer high-quality products and services, including distribution of fiberglass materials.

One such business is Fiberlay Inc, a minority-owned company based in Seattle, Washington. They have been providing composite materials since 1953 and have become one of the leading distributors of fiberglass materials in the Pacific Northwest region. Fiberlay offers a wide range of products for marine, automotive, aerospace, and industrial applications.

Another example is Composite Envisions, a minority-owned business based in Wisconsin that specializes in carbon fiber fabrics, Kevlar fabrics, and other composite materials. They offer a variety of products for hobbyists and professionals alike and pride themselves on their exceptional customer service.

Minority-owned businesses also play a significant role in the fiberglass industry.

Minority-owned businesses have made significant contributions to the American economy over the years. In fact, according to data from the US Department of Commerce's Minority Business Development Agency (MBDA), minority-owned firms contributed over $1 trillion to the US economy in 2015 alone.

One such business is The Composites Group, which is headquartered in Ohio and has been providing custom composites solutions since 1988. The company specializes in manufacturing high-performance thermoset composites for various industries like automotive, construction equipment, electrical insulation systems & more.

Another example is Gibco Flex-Mold, which is located in Florida and provides custom-made flexible molds for composite parts manufacturing. Gibco Flex-Mold has been serving customers worldwide for over 30 years with their innovative technology and expertise.

These businesses offer high-quality products and services, including distribution of fiberglass materials.

Minority-owned businesses in the fiberglass industry are known for their high-quality products and services. These businesses often have a more personal touch than larger corporations, which allows them to provide better customer service and support.

One such business is Fiberglass Coatings, a minority-owned company based in Florida that specializes in providing composite materials for marine applications. They offer a wide range of products like resins, gelcoats, paints, and other supplies needed for boat repair & maintenance. Fiberglass Coatings has been serving the marine industry since 1979 with exceptional customer service.

Another example is Express Composites, which is located in California and provides custom composite solutions for various industries like aerospace, automotive, medical devices & more. They have been providing innovative solutions to their customers since 1997 with their highly skilled team of experts.

Partnering with minority-owned fiberglass suppliers can help promote diversity and support small businesses.

Partnering with minority-owned fiberglass suppliers not only helps promote diversity but also supports small businesses. By supporting these businesses, you are helping to create jobs and stimulate economic growth within your community.

One such business is Advanced Composite Products & Technology (ACPT) based in California that specializes in manufacturing advanced composites structures for military aircrafts & commercial airlines. ACPT has received several awards from the US Department of Defense for its contribution to the aerospace industry as well as being recognized by Boeing as a supplier of excellence.

Another example is Carbon-Core Corp, which is headquartered in Maryland and provides lightweight core materials for various industries like marine, transportation & construction equipment. Carbon-Core has been providing eco-friendly solutions to its customers since 2000 while promoting sustainability through its innovative technology.

Top Fiberglass Suppliers in the USA: Women-Owned Businesses

Women-Owned Businesses as Top Fiberglass Suppliers in the USA

Women-owned businesses are making a name for themselves. These companies have been providing high-quality fiberglass products for various industries and applications. They are known for their expertise and innovative solutions that cater to the specific needs of their clients.

One of the leading women-owned businesses in this industry is AOC Resins. Founded by Dr. Elaine Armfield, AOC Resins is headquartered in Collierville, Tennessee, with manufacturing facilities located across North America, Europe, and Asia. The company offers a wide range of fiberglass products such as unsaturated polyester resins, vinyl ester resins, gelcoats, and bonding pastes.

Another notable women-owned business is Strongwell Corporation. Based in Bristol, Virginia, Strongwell has been supplying fiberglass products since 1956. Their offerings include pultruded fiberglass structural shapes and plates that are used for various applications such as bridges, pedestrian walkways, cooling towers, and marine structures.

Business Headquarters Located in Pennsylvania

Pennsylvania is home to several top fiberglass suppliers that are also women-owned businesses. One of them is Bedford Reinforced Plastics (BRP), which was founded by Joyce Paisley-Smith in 1974. BRP's headquarters is located in Bedford, Pennsylvania and they specialize in custom-engineered fiberglass-reinforced polymer (FRP) solutions for industrial applications such as chemical processing equipment and water treatment systems.

Another Pennsylvania-based company is Fiber-Tech Industries Inc., which was established by Patricia Beckman-Cramer in 1983. Fiber-Tech's headquarters is situated in Washington Court House and they offer a variety of FRP panels that are used for truck bodies/trailers, recreational vehicles (RVs), cold storage facilities, and more.

Vetrotex Products Among Offerings of Top Fiberglass Suppliers

Vetrotex is a well-known brand in the fiberglass industry and some of the top women-owned businesses in this sector offer Vetrotex products among their offerings. One of them is Glasforms Inc., which was founded by Karen Armstead in 1972. Glasforms' headquarters is located in Birmingham, Alabama and they specialize in pultruded fiberglass products such as rods, tubes, and custom profiles.

Another company that offers Vetrotex products is Composite Advantage LLC. Founded by Scott Reeve and Anita Gwaltney-Reeve in 2005, Composite Advantage's headquarters is situated in Dayton, Ohio. They provide innovative composite solutions for infrastructure applications such as bridge decks, rail platforms, and waterfront structures.

Fiberglass Manufacturers and Suppliers in Johor Bahru, Malaysia

Wide Range of Quality Fiberglass Products

Johor Bahru is home to several reputable fiberglass manufacturers and suppliers that offer a wide range of quality products. From fiberglass sheets, panels, pipes to tanks and other custom-made products, customers can choose from a variety of options based on their specific needs. These manufacturers use advanced technology and high-quality materials to produce durable and long-lasting fiberglass products.

One of the most significant advantages of buying fiberglass products in Johor Bahru is their exceptional quality. The manufacturers here use top-quality raw materials that ensure the final product's durability, strength, and resistance to harsh environmental conditions. They follow strict quality control measures throughout the manufacturing process to ensure that each product meets industry standards.

Growing Industry

The fiberglass industry in Johor Bahru has been growing steadily over the years due to its high demand across various industries such as construction, automotive, marine, aerospace, electricals & electronics, etc. The city's strategic location near Singapore also makes it an ideal place for businesses looking for cost-effective manufacturing solutions.

The growth of this industry has resulted in increased competition among manufacturers and suppliers in Johor Bahru. As a result, companies are continuously innovating new technologies and techniques to stay ahead of the competition while still maintaining high-quality standards.

Customization Options Available

Another advantage of working with fiberglass manufacturers in Johor Bahru is their ability to provide customized solutions based on customer requirements. Whether it's designing unique shapes or sizes or incorporating specific features into the final product - these manufacturers can provide tailored solutions that meet individual needs.

For instance, if you need a customized water tank for your business or home usage with specific dimensions or features like UV protection or insulation properties - you can get it done by working with one of these manufacturers. They have skilled professionals who can understand your requirements and design products that meet your needs.

Final Thoughts on Fiberglass Manufacturer

Reducing Plastic Waste with Fiberglass Manufacturers

Fiberglass manufacturers play a significant role in reducing plastic waste. As the world becomes more aware of the environmental impact of plastic, many industries are turning to fiberglass as a sustainable alternative. Unlike plastic, which can take hundreds or even thousands of years to decompose, fiberglass is recyclable and can be used for multiple purposes.

In addition to being environmentally friendly, fiberglass has several advantages over traditional materials like wood and metal. For example, fiberglass is lighter than steel and stronger than aluminum. It also has excellent thermal insulation properties, making it an ideal material for building insulation.

Choosing a Reliable Fiberglass Manufacturer

Choosing a reliable fiberglass manufacturer is crucial for ensuring quality and safety. When selecting a manufacturer, it's essential to consider their experience in the industry, reputation among customers, and certifications they hold.

A reputable fiberglass manufacturer should have a proven track record of producing high-quality products that meet industry standards. They should also use state-of-the-art equipment and adhere to strict safety protocols when manufacturing their products.

The Durability of Fiberglass

Fiberglass is known for its durability and resistance to wear and tear. It can withstand harsh weather conditions without cracking or warping, making it an ideal material for outdoor applications such as boat hulls or wind turbine blades.

Fiberglass is also resistant to corrosion from chemicals and saltwater exposure. This makes it an excellent choice for industrial applications where materials are exposed to harsh environments regularly.

Wide Range of Products Offered by Fiberglass Manufacturers

Fiberglass manufacturers offer a wide range of products designed for various industries such as construction, transportation, marine, aerospace, and renewable energy. These products include everything from insulation batts to custom-made parts such as pipes, tanks or ductwork.

Working with a fiberglass manufacturer allows businesses to access these specialized products at competitive prices while ensuring that they meet their specific requirements.

Cost Savings with Fiberglass Manufacturers

Working with a fiberglass manufacturer can lead to significant cost savings in the long run. Although fiberglass may be more expensive than some traditional materials upfront, its durability and low maintenance costs make it a cost-effective option over time.

For example, fiberglass insulation can save homeowners up to 40% on their energy bills compared to other types of insulation. Similarly, using fiberglass in wind turbine blades can increase their lifespan by up to 25 years, resulting in significant cost savings for renewable energy companies.

Fiberglass Manufacturers and Suppliers in Cheras, Malaysia

Choosing a reliable fiberglass manufacturer is crucial to ensure that the products you receive are of high quality and meet your specific needs. In Cheras, Malaysia, there are various manufacturers and suppliers of fiberglass products to choose from.

Among the top fiberglass manufacturers and suppliers in Selangor, Malaysia are OCM Enterprise. They offer a wide range of high-quality fiberglass products such as tanks, pipes, gratings, and more. With their years of experience in the industry, they have established themselves as a trusted provider of fiberglass solutions.

If you're looking for top-rated fiberglass manufacturers and suppliers in the USA, Thomas can provide you with comprehensive company summaries to help you make an informed decision. There are also several capable fiberglass fabrication companies and suppliers that can cater to your unique requirements.

For those who prioritize diversity status when choosing a supplier or manufacturer, there are several options available in the USA. Some of these include minority-owned businesses like Fiber-Tech Industries Inc., women-owned businesses like Strongwell Corporation, and others.

In Johor Bahru, Malaysia there are also many reputable manufacturers and suppliers of fiberglass products available for your consideration.

It's important to do your research beforehand. Look for companies with good reviews and ratings from previous customers. Consider their experience in the industry as well as their capabilities.

In conclusion, finding a reliable fiberglass manufacturer or supplier is essential if you want to get high-quality products that meet your specific requirements. Take time to research and compare different options before making a final decision.

FAQs

What types of fiberglass products can I find at OCM Enterprise?

OCM Enterprise offers a wide range of high-quality fiberglass products including tanks, pipes, gratings, panels, ladders & platforms.

How can I determine if a particular supplier is reliable?

You can determine if a supplier is reliable by checking their reviews and ratings from previous customers. You can also consider their experience in the industry as well as their capabilities.

What are some factors to consider when choosing a fiberglass manufacturer or supplier?

Some factors to consider include the company's experience, capabilities, reviews & ratings from previous customers, and whether they offer products that meet your specific requirements.

Can I find minority-owned or women-owned fiberglass suppliers in the USA?

Yes, there are several minority-owned and women-owned businesses that specialize in fiberglass manufacturing and supply in the USA.

How important is it to choose a reliable fiberglass manufacturer?

Choosing a reliable fiberglass manufacturer is crucial if you want to get high-quality products that meet your specific needs. A reliable manufacturer will also ensure timely delivery of your order.

10 Pembekal dan Pengeluar Terbaik Fiberglass di Malaysia

Bagaimana Fiberglass Dibuat? Proses Pembuatan dan Aplikasinya

Discover the benefits of Fiberglass-Reinforced Plastic (FRP) grating in industries like oil and gas, chemical processing, marine, and more. Mui Fatt offers durable, corrosion-resistant FRP gratings for diverse applications.

Learn about the risks of fiberglass application, importance of safety measures, and DOSH compliance requirements. Discover best practices for a secure working environment.

Explore Mui Fatt's expertise in OEM fiberglass manufacturing, delivering durable, lightweight, and corrosion-resistant products customized for various industries.

Discover how fiberglass camouflage panels are transforming industries in Malaysia. Explore their applications, working principle, and the benefits they bring to telecommunications.

Discover the benefits of FRP secondary containment tanks for storing hazardous substances. With their durability, corrosion resistance, and compliance with environmental regulations, FRP secondary containment tanks provide a reliable and long-lasting solution for safeguarding the environment and ensuring the containment of hazardous materials.

Rotomolding and injection molding are two common methods used for manufacturing plastic dustbins. This article compares the pros and cons of each method to help you decide which is right for your needs

Learn about the importance of sump covers for odor control in Malaysia and factors to consider when selecting and installing them. Discover how fiberglass sump covers can help meet regulatory requirements and improve sewer system performance.

Looking for lightweight and durable planters for your indoor or outdoor space? Check out our fiberglass planter pots! Available in a variety of sizes and designs, these versatile planters are weather-resistant and easy to move. Shop now at Mui Fatt and elevate your greenery game!

Explore the advantages of using fiberglass roofing as a durable and cost-effective alternative to traditional site hoarding materials in Malaysia’s construction industry.

Fiberglass corner guards for superior wall protection. Our corrosion-resistant and sturdy corner guards are ideal for warehouses, factories, and other industrial settings where durability is crucial.

FRP structural profiles are revolutionizing walkway construction, offering a corrosion-resistant, lightweight, and non-conductive alternative to steel. Learn how these innovative materials enhance safety, durability, and cost efficiency, making them the preferred choice for various walkway applications.

Upgrade your cold truck body with our high-quality fiberglass flat sheets. Designed to withstand extreme temperatures and provide superior insulation. Our fiberglass flat sheets can ensure your cargo arrives at its destination in perfect condition.

A leaking roof can be a source of stress and anxiety for homeowners. Don’t suffer from the pain any longer! Read on for tips and our solution for you.

The three main components of a waste management system are trash bins, recycling bins and dumpsters.

Benefits of FRP in Landscaping That You Might Not Know.

Is potable water stored in a PE water tank safe to be consumed?

The Inter-function of Polymer Science and Mechanical (Composite Materials)

We are looking for Talents in Polymer Science | Mechanical (Composite Material) | Join us now!!

Prof. Dr Mohd Yazid Yahya from Centre of Excellence UTM (Centre for Advanced Composite Materials - CACM UTM) had visited us on 21 February 2023 for a session of Industrial Knowledge sharing on Composite Structure

Wastewater Treatment protects humans and the ecosystem from harmful and toxic elements found in wastewater.

Our products is listed and available in reputable trading company!

Coming to new year 2023, we found a research on top brand of septic in malaysia with a research done by TrustedMalaysia.com. The reseach was conducted by them and comparing across numerous brand in Malaysia. We are glad that we got 2 out 5 in the top 5.

In the writeup also features the benefits of spectic tank made from different material. Other FAQ also answer well in the website.

Population equivalent (PE) or unit per capita loading, or equivalent person (EP), is a parameter for characterizing industrial wastewaters. It essentially compares the polluting potential of an industry (in terms of biodegradable organic matter) with a population (or certain number of people), which would produce the same polluting load.? In other words, it is the number expressing the ratio of the sum of the pollution load produced during 24 hours by industrial facilities and services to the individual pollution load in household sewage produced by one person in the same time. This refers to the amount of oxygen-demanding substances in wastewater which will consume oxygen as it bio-degrades, usually as a result of bacterial activity.

Our Latest Blog

-

01

-

02

-

03

FRP Handrail Project for Majlis Perbandaran KuantanJun 12, 2025 -

04

-

05