In 2024, we successfully supplied a fully assembled FRP staircase to a sewage treatment plant (STP) in Kota Kinabalu via sea freight. Constructed using high-strength FRP pultruded profiles and molded grating, this custom-built solution provides long-term durability, corrosion resistance, and ease of installation—making it ideal for harsh wastewater environments.

FRP Lamination for Mild Steel Equipment, Chemical Plant

02 May 2025

-

Client: Yinpolin Agriculture Sdn Bhd (now Hextar Fert Sdn Bhd)

Client: Yinpolin Agriculture Sdn Bhd (now Hextar Fert Sdn Bhd) -

Start Year: 2013 – Ongoing

-

Application: FRP clear coating on mild steel I-Beams, chemical tanks, handrails, and equipment supports

-

Method: Hand lay-up fiberglass lamination using clear resin + fiberglass mat

-

Purpose: Protect against chemical corrosion, increase structural lifespan, and reduce steel replacement frequency

Back in 2013, Yinpolin Agriculture Sdn Bhd approached us with a recurring issue—corrosion on their steel components due to aggressive chemical exposure in their fertilizer production plant. To address this, we proposed FRP lamination using clear resin and fiberglass matting. Over the years, our FRP application has proven effective in forming a seamless corrosion barrier, increasing the service life of their steel handrails, I-beams, and chemical tanks. Today, as Hextar Fert Sdn Bhd, they continue to trust our solutions to maintain safety and integrity in harsh environments.

Why FRP Lamination is Ideal for Chemical Fertilizer Plants

Corrosion Resistance for Aggressive Environments

Steel exposed to acidic or alkaline chemicals is prone to rapid rusting. FRP offers superior chemical resistance and does not degrade easily.

Long-Term Durability and Cost Efficiency

Instead of frequent steel replacements, our FRP lining extends asset lifespan by up to 3X with minimal maintenance.

Customizable for Irregular Structures

With hand lay-up lamination, even oddly shaped steel structures—like pipe joints, flange edges, or welded connections—can be fully coated.

Our Hand Lay-Up FRP Lining Process

-

Surface Preparation: Grit blasting and degreasing mild steel surface

-

Base Resin Application: High-quality clear polyester resin

-

Matting & Lamination: 1–3 layers of fiberglass mat laminated manually

-

Final Curing: Ensures structural bonding and chemical resistance

-

Post-Coating Inspection: Quality control and customer verification

Our long-term supply relationship with Hextar Fert showcases our commitment to quality and service consistency. We've supported plant expansion, shutdown maintenance, and even emergency repair coating services over the years. Our skilled team can work within tight downtime limits, ensuring zero compromise on plant operation.

Need corrosion protection for your chemical or steel structures? Explore our FRP Lamination & Lining Solutions or talk to us via WhatsApp or email at sales@muifatt.com.my for consultation.

Frequently Asked Questions (FAQs)

What makes FRP lamination better than paint coating?

Paints provide superficial protection, while FRP forms a reinforced barrier that resists chemicals and physical impact.

Can FRP lamination be applied on-site?

Yes, we perform on-site FRP coating even for confined or elevated areas using scaffolding and safety-certified crews.

How long does a typical FRP lamination last?

With proper application and maintenance, FRP lining can last for years in aggressive industrial conditions.

#FRPlamination #steelprotection #fiberglasscoating #chemicaltanklining #FRPMalaysia

Disclaimer:-

The content on this site is for general information and entertainment purposes and does not constitute legal counsel. We strive to keep our information as accurate as possible. However, we make no warranties about the completeness, accuracy, reliability, suitability, or availability with respect to the information contained on this page. You should rely on this information at your own risk. This website may include links to other third-party sites. These links are provided as a convenience to you as a reader, user, or browser only. We make no representation, warranty, or guarantee, nor do we endorse or take responsibility for any of the content of such sites.

Stay in touch with us if you’re interested in hearing from us promptly.

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

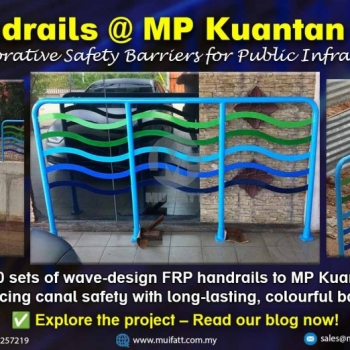

FRP Handrail Project for Majlis Perbandaran Kuantan

In September 2015, Mui Fatt supplied approximately 250 sets of wave-designed FRP pultruded handrails to Majlis Perbandaran Kuantan via Kerjaya Kibar Sdn Bhd. Installed at various canal-side locations, these handrails were chosen for their superior durability, corrosion resistance, and maintenance-free performance in outdoor environments. This project reflects our commitment to safety, functionality, and urban aesthetics using long-lasting FRP solutions.

Klinik Kesihatan 2 Sendayan GRP Tank Project

The Klinik Kesihatan 2 Sendayan project aimed to provide a reliable, space-efficient water storage solution. Our GRP sectional panel tank, pre-installed and ready for use, ensures minimal site disruption and quick commissioning. This project underlines Mui Fatt’s ability to tailor GRP solutions to client specifications, fulfilling both size constraints and capacity requirements.

FRP Grating Supply for RNR Restroom Drain Systems

In 2024, Mui Fatt supplied approximately 200m² of MG25-100 grey FRP molded gratings for toilet drain systems at RNR Simpang Pulai and RNR Gurun. This was a major restroom renovation under the PLUS Highway upgrade initiative. Our gratings provided a durable, anti-slip, and corrosion-resistant solution for enhanced public hygiene and long-term service performance.

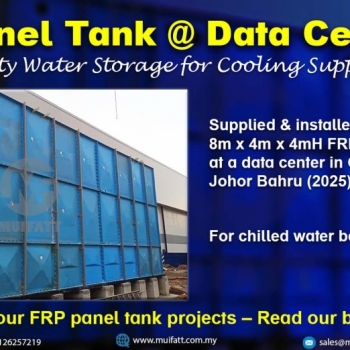

2025 FRP Sectional Water Tank Supply to Johor Data Center

In 2025, Mui Fatt successfully supplied two units of FRP sectional panel water tanks, each measuring 8m x 4m x 4mH, for a high-performance data center located in Gelang Patah, Johor Bahru. Delivered via contractor Timesfly International, these tanks ensure safe, large-volume water storage with corrosion-resistant performance tailored for critical facilities like data centers.

FRP Planter Pot Supply to Sunway Carnival Mall

In 2022, Mui Fatt supplied 40 different sizes of grey FRP planter pots to Sunway Carnival Mall for indoor landscaping. This continued collaboration demonstrates Sunway's trust in our FRP products for enhancing their spaces. Read on to learn how our solution met their landscaping goals and the benefits of choosing FRP for mall projects.

FRP Tank Supply for Magsoft Wastewater Projects

Mui Fatt has been the trusted supplier of FRP tanks for Magsoft’s wastewater treatment systems since 2022. These tanks are engineered to resist harsh chemicals and built to meet the unique layout and specifications of each treatment plant.

Large FRP Signage Board for Plantation Entrance

In 2024, Mui Fatt successfully fabricated and delivered 20 large-size fiberglass-reinforced plastic (FRP) signage boards for use as plantation entrance stands. Designed for high durability, weather resistance, and customization, these signage boards can be adapted for factory and plant usage across industries.