Discover the process, benefits, and sustainability of FRP lamination. This article covers everything from application steps to industry-specific insights and FAQs.

Corrosion in Wastewater Treatment Plant? Fiberglass Solutions!

01 Mar 2024

Corrosion in Wastewater Treatment Plant? Fiberglass Solutions!

Corrosion in Wastewater Treatment Plant? Fiberglass Solutions!

- Corrosion Challenges

- Case Study Insights

- Fiberglass Solutions

- Benefits of Fiberglass

- Comparative Analysis

- Implementation Strategies

- Operational Success Stories

- Future Perspectives

- Expert Recommendations

- Summary

- Frequently Asked Questions

- What are the common challenges related to corrosion in wastewater treatment plants?

- How can fiberglass solutions help combat corrosion in wastewater treatment plants?

- Why should one consider implementing fiberglass solutions over traditional materials like steel or concrete?

- What are some key benefits of using fiberglass materials in a wastewater treatment plant setting?

- How can operational success stories influence decision-making regarding anti-corrosion strategies in wastewater treatment facilities?

In the realm of wastewater treatment plants, the battle against corrosion rages on. While these facilities play a crucial role in purifying our water supply, they face a relentless foe in the form of corrosion. The contrast between safeguarding equipment and infrastructure from deterioration while maintaining operational efficiency is a constant challenge.

Corrosion not only threatens the structural integrity of vital components but also poses environmental risks and financial burdens. Understanding the mechanisms behind corrosion in wastewater treatment plants is essential for implementing effective prevention strategies and prolonging equipment lifespan. Join us as we delve into the world of combating corrosion in these critical facilities.

Corrosion Challenges

Climate Impact

Climate Impact

Corrosion in wastewater treatment plants can worsen due to extreme weather conditions. High humidity and temperature changes speed up the corrosion process. Severe storms and floods can introduce corrosive elements into the plant's infrastructure.

Some materials used in wastewater treatment facilities are more prone to corrosion than others. For instance, steel and iron are highly susceptible to corrosion, leading to deteriorating infrastructure over time. In contrast, fiberglass is a corrosion-resistant material that offers long-lasting protection against deterioration.

Material Susceptibility

Different materials used in wastewater treatment plants have varying levels of susceptibility to corrosion. Steel and iron are common materials highly vulnerable to corrosion, causing infrastructure decay over time. On the other hand, fiberglass stands out as a corrosion-resistant material providing lasting defense against degradation.

Corrosion-related issues significantly impact operational costs at wastewater treatment plants by necessitating frequent repairs and replacements due to corrosion damage. By implementing preventive measures against corrosion, such as using resistant materials like fiberglass or applying protective coatings, long-term operational costs can be reduced considerably.

Case Study Insights

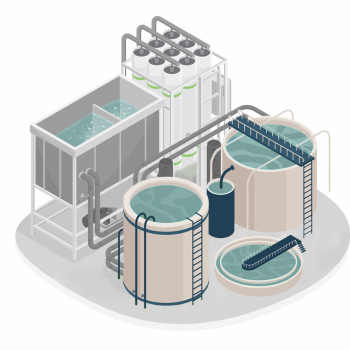

Infrastructure Failures

Corrosion in wastewater treatment plants can lead to infrastructure failures. When pipes, tanks, and structures corrode, they are prone to leaks or even collapses. These failures not only disrupt the plant's operations but also pose significant environmental risks. Imagine a corroded pipe bursting and leaking untreated wastewater into nearby water bodies, endangering aquatic life and public health.

Regular maintenance is crucial for preventing deterioration caused by corrosion in wastewater treatment plants. Conducting routine inspections allows operators to identify any signs of corrosion early on before it escalates into a major issue. By promptly addressing these corrosion issues through cleaning and repairs, the lifespan of equipment can be extended significantly. For instance, scheduling regular checks on metal components like pumps or valves helps catch corrosion before it compromises their functionality.

Maintenance Needs

To avoid costly damages associated with corrosion in wastewater treatment plants, investing in corrosion-resistant materials and implementing preventive measures is essential. While repairing or replacing corroded equipment can be expensive, using materials that resist corrosion from harsh chemicals present in wastewater can result in long-term cost savings for the plant. Adopting preventive strategies such as cathodic protection systems can help mitigate the impact of corrosive elements on critical infrastructure.

Corrosion-related damages have significant cost implications, making it imperative for wastewater treatment plants to prioritize proactive maintenance practices aimed at combating this issue effectively. By allocating resources towards regular upkeep and employing anti-corrosion technologies where necessary, plants can reduce the likelihood of unexpected breakdowns due to deteriorating infrastructure caused by corrosion.

Fiberglass Solutions

Corrosion Resistance

Using fiberglass in wastewater treatment plants can significantly reduce the impact of corrosion. Fiberglass exhibits exceptional resistance to chemical attacks, making it a perfect choice for harsh wastewater environments. Applying corrosion-resistant coatings can further improve the longevity of susceptible surfaces.

In these facilities where various chemicals are handled, employing materials like fiberglass that offer high chemical resistance is vital to combat corrosion effectively. These materials can endure prolonged exposure to corrosive substances without deteriorating. Proper management and monitoring of chemicals play a crucial role in preventing accelerated corrosion rates.

Chemical Resistance

Wastewater treatment plants face the challenge of dealing with a wide array of chemicals that contribute to corrosive processes within the infrastructure. By utilizing materials such as fiberglass products, these facilities can ensure their structures remain intact despite constant exposure to harmful substances. Effective chemical management practices are essential in maintaining the integrity and longevity of equipment and structures within wastewater treatment plants.

Benefits of Fiberglass

Durability

Fiberglass is a popular choice in wastewater treatment plants due to its corrosion-resistant properties. It offers exceptional durability, standing strong against harsh conditions that can cause corrosion. By opting for fiberglass materials, the need for frequent repairs and replacements is significantly reduced. This longevity ensures the smooth operation of the plant over an extended period.

Fiberglass shines by being lightweight and straightforward to install. Its lightweight nature makes handling easier during installation, cutting down on time and costs associated with labor. The simplicity of installing fiberglass components streamlines complex processes, making construction more efficient overall. Pre-fabricated fiberglass parts simplify installations further by reducing the need for intricate assembly steps.

Operational Efficiency

The use of fiberglass in wastewater treatment plants contributes to operational efficiency through its low maintenance requirements. Its resistance to corrosion means less time spent on upkeep tasks such as repairs or replacements compared to other materials susceptible to degradation in such environments. With minimal maintenance needs, plant operators can focus their efforts on optimizing plant performance rather than constantly addressing material-related issues.

In addition to operational efficiency benefits, choosing fiberglass can enhance safety within wastewater treatment facilities. Fiberglass's non-conductive properties make it a safer option compared to metal alternatives when dealing with electrical equipment or components within the plant environment. This added layer of safety reduces risks for workers and enhances overall workplace safety standards.

Comparative Analysis

Traditional vs Fiberglass

Traditional materials such as steel and iron are often used in wastewater treatment plants, but they are highly prone to corrosion. On the other hand, fiberglass provides a corrosion-resistant alternative that boasts exceptional durability. When comparing these options, it's crucial to consider the longevity and maintenance requirements of each material.

Fiberglass tanks have a significant advantage over traditional materials due to their resistance to corrosion. For instance, steel tanks may require frequent inspections and repairs due to rust and degradation caused by exposure to harsh chemicals in wastewater treatment facilities. In contrast, fiberglass tanks can withstand corrosive environments without deteriorating, leading to reduced maintenance needs and longer service life.

Cost-Benefit

Assessing the cost-benefit ratio of utilizing corrosion-resistant materials is vital for ensuring the efficiency of wastewater treatment plants. While investing in corrosion prevention measures like fiberglass tanks may involve higher upfront costs compared to traditional materials like steel or iron, the long-term savings can be substantial. By evaluating potential cost savings from decreased maintenance expenses and minimizing infrastructure failures due to corrosion, plant operators can make informed decisions about material selection.

The initial investment in fiberglass equipment might seem costly at first glance; however, considering its extended lifespan with minimal repair requirements makes it a financially sound choice for wastewater treatment plants aiming for long-term sustainability. Moreover, reducing downtime associated with repairing or replacing corroded components can lead to increased operational efficiency and overall cost-effectiveness in the long run.

Implementation Strategies

Planning Process

Proper planning is crucial to tackle corrosion in wastewater treatment plants effectively. Identifying vulnerable areas and choosing corrosion-resistant materials are key aspects of the planning process. Involving corrosion prevention experts during the planning stage ensures that robust strategies are put in place.

For instance, if a specific area within the plant is prone to corrosion due to constant exposure to corrosive substances, selecting appropriate materials like fiberglass can significantly reduce the risk of degradation over time. By involving experts early on, such as corrosion engineers or consultants, specialized knowledge can be applied to tailor preventive measures according to the plant's unique needs.

Execution Steps

Implementing corrosion prevention techniques involves a series of critical steps for optimal results. This includes meticulous material selection based on environmental factors and potential risks, thorough surface preparation before applying protective coatings, and ensuring proper application methods are followed diligently throughout the process.

Regular inspections play a vital role in identifying early signs of corrosion or wear on surfaces, allowing for timely maintenance interventions before significant damage occurs. Collaboration among different stakeholders such as engineers responsible for design, contractors executing preventive measures, and maintenance personnel overseeing long-term care is essential for seamless execution and sustained protection against corrosion challenges in wastewater treatment plants.

Operational Success Stories

Improved Efficiency

Corrosion-resistant materials play a crucial role in enhancing the efficiency of wastewater treatment plants. By using corrosion-resistant materials, these plants experience reduced downtime caused by equipment failures, ensuring continuous operations. This uninterrupted workflow leads to increased productivity and smoother plant functioning overall. For instance, stainless steel pipes are commonly used due to their resistance to corrosion from the harsh chemicals present in wastewater.

The durability of corrosion-resistant materials translates into lower maintenance requirements. With reduced maintenance needs, staff can focus on other critical tasks within the plant, further boosting productivity levels. The enhanced durability also means that equipment lasts longer before needing replacement or repairs, saving both time and resources for the facility.

Reduced Downtime

Corrosion-related failures pose a significant risk of causing prolonged downtime in wastewater treatment plants. By implementing effective corrosion prevention measures like using protective coatings or cathodic protection systems, these facilities can mitigate the chances of unexpected equipment breakdowns significantly. Planned maintenance schedules and timely repairs are essential components of preventing extensive disruptions to plant operations.

Future Perspectives

Sustainability Goals

Incorporating corrosion-resistant materials in wastewater treatment plants is crucial for achieving sustainability goals. By using such materials, equipment lasts longer, reducing the need for frequent replacements. This, in turn, minimizes the environmental impact by decreasing resource consumption and waste generation. Moreover, preventing leaks and infrastructure failures through corrosion prevention helps to maintain water quality within the treatment plant and surrounding ecosystems.

Advanced coatings and composites are examples of technological advancements that have revolutionized corrosion prevention strategies in wastewater treatment plants. These innovative materials provide enhanced protection against corrosion, ensuring the longevity of critical equipment and infrastructure within the facility. Staying updated with technological advancements allows plant operators to optimize their corrosion prevention methods continuously, improving operational efficiency while minimizing maintenance costs.

Technological Advancements

- Incorporating corrosion-resistant materials aligns with sustainability goals.

- Longer lifespan of equipment reduces environmental impact.

- Preventing leaks maintains water quality and protects ecosystems.

Sustainability Goals

- Advanced coatings offer superior protection against corrosion.

- Keeping up with technology optimizes corrosion prevention strategies.

Expert Recommendations

Maintenance Practices

Maintenance Practices

Regular maintenance practices are key to combatting corrosion in wastewater treatment plants. Inspections, cleaning, and repairs must be routine tasks to prevent deterioration. By training staff on the best corrosion prevention methods, the facility can ensure effective maintenance procedures.

Implementing a comprehensive maintenance program is vital for the longevity of equipment and infrastructure at wastewater treatment plants. Neglecting regular inspections or delaying necessary repairs can lead to costly damages caused by corrosion.

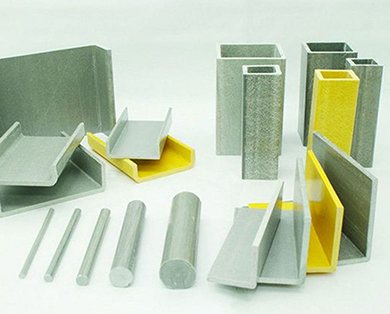

Material Selection

Selecting appropriate materials plays a crucial role in preventing corrosion in wastewater treatment plants. When choosing materials, factors like chemical resistance, durability, and ease of installation should be considered carefully. Fiberglass stands out as a popular choice due to its exceptional corrosion resistance and long-term performance.

The right material selection not only prevents corrosion but also ensures the efficient operation of the plant's systems over an extended period. Investing in high-quality materials upfront can save significant costs on repairs and replacements down the line.

Summary

You've now explored the significant impact of corrosion in wastewater treatment plants and how fiberglass solutions can effectively combat this challenge. From understanding the corrosion challenges to delving into operational success stories, you've gained insights into the benefits of fiberglass materials over traditional options. By considering expert recommendations and future perspectives, you're well-equipped to implement strategies that ensure long-term success in maintaining infrastructure integrity.

Take action today by evaluating your wastewater treatment plant's corrosion vulnerabilities and considering the adoption of fiberglass solutions. Your proactive approach can not only enhance operational efficiency but also contribute to environmental sustainability. Embrace the opportunity to safeguard your facility against corrosion and secure a resilient future for your wastewater treatment operations.

Talk to us for your project today! WhatsApp or email – sales@muifatt.com.my . We guarantee our expertise to you.

Frequently Asked Questions

What are the common challenges related to corrosion in wastewater treatment plants?

Corrosion in wastewater treatment plants can lead to equipment degradation, increased maintenance costs, and potential environmental hazards due to leaks or failures. Identifying and addressing corrosion promptly is crucial for plant efficiency.

How can fiberglass solutions help combat corrosion in wastewater treatment plants?

Fiberglass offers excellent resistance to corrosive elements found in wastewater environments. Its durability, lightweight nature, and ease of installation make it a popular choice for combating corrosion in various components like tanks, pipes, and structures.

Why should one consider implementing fiberglass solutions over traditional materials like steel or concrete?

Fiberglass provides superior corrosion resistance compared to steel or concrete. It requires minimal maintenance, has a longer lifespan, and is more cost-effective in the long run due to reduced repair and replacement needs.

What are some key benefits of using fiberglass materials in a wastewater treatment plant setting?

Fiberglass materials offer advantages such as high strength-to-weight ratio, non-conductivity properties (useful for electrical insulation), UV resistance (ideal for outdoor installations), and customization options that cater to specific project requirements.

How can operational success stories influence decision-making regarding anti-corrosion strategies in wastewater treatment facilities?

Learning from successful implementations where fiberglass solutions have effectively mitigated corrosion issues can inspire confidence in decision-makers. Real-world examples showcasing improved performance and cost savings provide valuable insights for optimizing plant operations.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Aviation Safety: Exploring Aircraft Warning Spheres and Their Materials

Explores the role of fiberglass aircraft warning spheres in enhancing aviation safety across Malaysia's rapidly developing urban landscape.

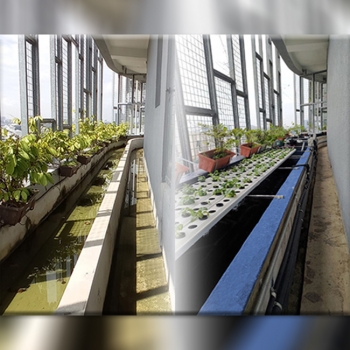

FRP Innovations in Wastewater Treatment Plant

Explore how Fiberglass-Reinforced Plastic (FRP) is transforming wastewater treatment globally with its superior corrosion resistance, durability, and cost-effectiveness, ensuring long-term sustainability and efficient water management.

The Ultimate Guide to FRP Composite Level Indicators

Explore the advantages of upgrading to Mui Fatt Marketing's FRP composite level indicator for your water tank. Learn about its durability, easy installation, and customization options.

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions

Discover how fiberglass solutions provide a sustainable and cost-effective method for odor control in Malaysian wastewater treatment plants, ensuring long-term operational efficiency and environmental stewardship.

FRP Panel Water Tanks in Data Center Cooling System

Data centers require robust and efficient cooling systems to maintain optimal performance. Fiberglass-Reinforced Plastic (FRP) panel water tanks play a crucial role in these systems by providing durable and efficient water storage solutions. This article explores the benefits of FRP panel water tanks, their importance in data center cooling, and addresses frequently asked questions.

Upgrade Wetland Infrastructure with Durable FRP Solutions

Explore the wonders of wetlands and learn about the importance of conservation efforts. Discover how Mui Fatt specializes in manufacturing high-quality FRP solutions tailored for wetland infrastructure, ensuring durability, sustainability, and lasting protection for these vital ecosystems.

Efficient FRP Insights in Wastewater Treatment

Explore the transformative impact of Fiberglass-Reinforced Plastic (FRP) technology in wastewater treatment plants. Discover how FRP has revolutionized plant infrastructure, addressing challenges such as corrosion and rising material costs. Learn why FRP is the material of choice for sustainable, cost-effective, and efficient water management solutions. Dive into future potential to understand why FRP is shaping the future of wastewater treatment.