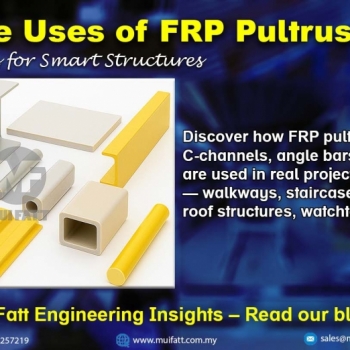

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Understanding FRP Lamination: Benefits & Process Demystified

06 Aug 2024

FRP Lamination: Benefits & Process Demystified

FRP Lamination: Benefits & Process Demystified

- Understanding FRP Lamination: Benefits & Process Explained

- Introduction

- What is FRP Lamination?

- Benefits of FRP Lamination

- Technical Specifications

- Comparison with Alternative Materials

- Case Study: Bandar Utama Aquaponics Project

- Price Range

- Industry-Specific Insights

- Role in Sustainability

- Conclusion

- Frequently Asked Questions (FAQs)

- What types of industries benefit most from FRP lamination?

- How long does the FRP lamination process take?

- Can FRP lamination be applied to any surface?

- What maintenance is required for FRP laminated surfaces?

- Is FRP lamination environmentally friendly?

- How do I get a quote for FRP lamination services?

Understanding FRP Lamination: Benefits & Process Explained

Introduction

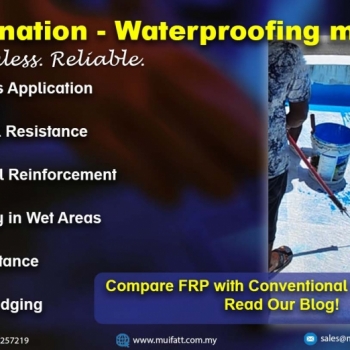

Fiberglass-reinforced plastic (FRP) lamination, also known as FRP lining or FRP coating, is a vital process in various industries due to its outstanding durability and resistance properties. This article delves into the benefits of FRP lamination, the process, its role in sustainability, and its cost considerations. While there are different terms such as FRP lining, FRP coating, and the ACEON laminate method, they all follow the same principles and processes as traditional fiberglass FRP lamination.

What is FRP Lamination?

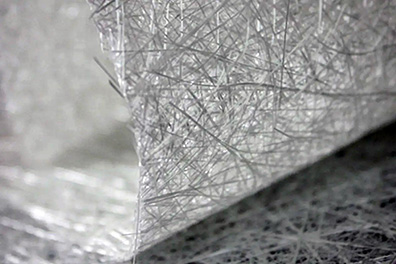

FRP lamination involves the application of layers of resin-impregnated fiberglass onto surfaces to create a durable, protective barrier. This method is synonymous with FRP lining and coating, ensuring robust protection against corrosion, chemicals, and physical abrasion.

FRP lamination involves the application of layers of resin-impregnated fiberglass onto surfaces to create a durable, protective barrier. This method is synonymous with FRP lining and coating, ensuring robust protection against corrosion, chemicals, and physical abrasion.

Step-by-Step Process of FRP Lamination

-

Surface Preparation:

-

Clean the surface thoroughly to remove any dirt, oil, or contaminants.

-

Sand or abrade the surface to create a rough texture for better adhesion.

-

-

Cutting the Fiberglass Fabric

-

Measure and cut the fiberglass fabric to the required size.

-

Ensure that the fabric pieces overlap slightly to avoid gaps.

-

-

Mixing the Resin

-

Prepare the resin according to the manufacturer's instructions.

-

Mix the resin with the appropriate hardener or catalyst to initiate the curing process.

-

-

Applying the Resin

-

Apply a layer of resin to the prepared surface using a brush or roller.

-

Place the cut fiberglass fabric onto the resin-coated surface.

-

Apply additional resin over the fabric to ensure it is fully saturated.

-

-

Rolling and Removing Air Bubbles

Rolling and Removing Air Bubbles-

Use a laminating roller to press the fabric into the resin, removing any air bubbles and ensuring even distribution.

-

Repeat the fiberglass lamination process for additional layers, as required, to achieve the desired thickness.

-

-

Curing

-

Allow the laminate to cure according to the resin manufacturer's guidelines.

-

Ensure the environment is dust-free and has a stable temperature for optimal curing.

-

-

Finishing

-

Once cured, inspect the laminate for any defects or imperfections.

-

Sand the surface if necessary to achieve a smooth finish.

-

Apply a topcoat or additional protective layers if required.

-

Benefits of FRP Lamination

-

Durability: FRP laminates are known for their exceptional strength and longevity, significantly extending the lifespan of industrial equipment.

-

Corrosion Resistance: These laminates provide superior protection against corrosive substances, making them ideal for industries dealing with harsh chemicals.

-

Abrasion Resistance: The laminated surfaces withstand physical wear and tear, ensuring minimal maintenance and repair needs.

-

Lightweight: Despite their strength, FRP laminates are lightweight, which makes them easy to install and handle.

Technical Specifications

Technical Specifications

-

Resin Types: Epoxy, vinyl ester, polyester

-

Fiberglass Fabric Types: Woven roving, chopped strand mat, biaxial cloth

-

Typical Thickness: 1.5mm to 6mm

-

Curing Time: 24 to 72 hours, depending on the resin and environmental conditions

-

Temperature Resistance: Up to 120 Celsius for standard resins; higher for specialized resins

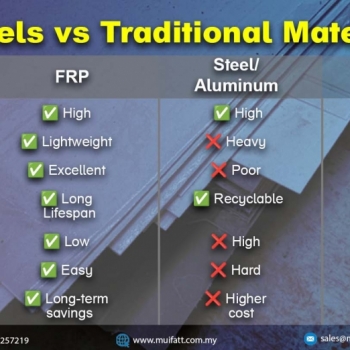

Comparison with Alternative Materials

|

Property |

FRP Lamination |

Metal Coatings |

Rubber Linings |

|---|---|---|---|

|

Durability |

High |

Medium |

Medium |

|

Corrosion Resistance |

Excellent |

Good |

Excellent |

|

Abrasion Resistance |

High |

Medium |

Good |

|

Weight |

Lightweight |

Heavy |

Medium |

|

Installation |

Easy |

Moderate |

Difficult |

|

Maintenance |

Low |

High |

Medium |

|

Cost |

Moderate |

High |

High |

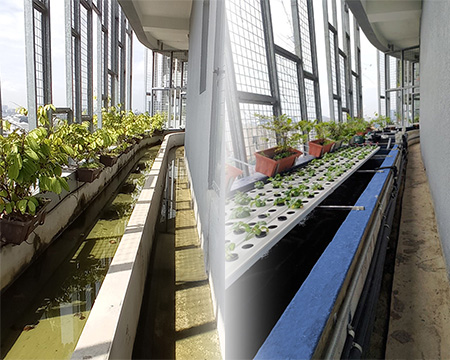

Case Study: Bandar Utama Aquaponics Project

In 2022, we completed a successful FRP lamination project at a 28-storey building in Bandar Utama. The project involved applying FRP lining to 14 levels of the building to support an aquaponic system. This comprehensive installation was crucial for creating a durable, moisture-resistant environment necessary for the aquaponics setup.

In 2022, we completed a successful FRP lamination project at a 28-storey building in Bandar Utama. The project involved applying FRP lining to 14 levels of the building to support an aquaponic system. This comprehensive installation was crucial for creating a durable, moisture-resistant environment necessary for the aquaponics setup.

Customer Testimonial

"The FRP lamination provided by Mui Fatt for our aquaponic system in Bandar Utama was exceptional. The quality and efficiency of the installation were top-notch, and the durability of the FRP lining has been instrumental in maintaining our system. We're extremely satisfied with the results and the professional service we received." - Michael R., Project Manager

Price Range

The cost of FRP lamination varies based on several factors, including the type of resin used, the complexity of the application, and the surface area being treated. On average, the price can range from RM 120 to RM 400 per square meter. Custom projects with specific requirements may incur higher costs due to the need for specialized materials and labor.

Industry-Specific Insights

-

Chemical Processing: FRP lamination is essential for protecting storage tanks, pipes, and reactors from corrosive chemicals.

-

Water Treatment: Provides a barrier against chemical attacks and abrasion in tanks, basins, and pipelines.

-

Oil & Gas: Used to protect infrastructure from harsh environmental conditions and corrosive substances.

Role in Sustainability

FRP lamination plays a crucial role in promoting sustainability in various ways:

-

Reduced Maintenance: The durability of FRP laminates means less frequent replacements and repairs, leading to lower material consumption and waste.

-

Energy Efficiency: The insulation properties of FRP laminates help in maintaining optimal temperatures, thereby reducing energy consumption.

-

Longevity: The extended lifespan of equipment protected by FRP laminates minimizes the need for manufacturing new components, conserving resources.

Conclusion

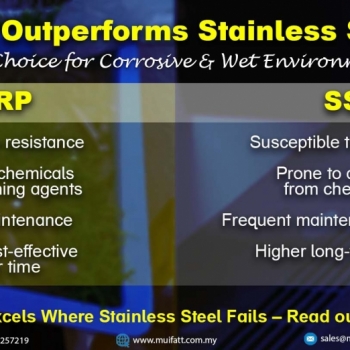

In today's industrial landscape, robust and reliable solutions to protect infrastructure from corrosion, chemicals, and abrasion are paramount. Explore FRP (Fiber Reinforced Plastic) lining and coating—a cutting-edge technology that offers unparalleled durability and resistance. Mui Fatt, with over 40 years of experience in the industry, specializes in providing top-notch FRP lining and coating services designed to extend the lifespan of tanks, pipes, and other industrial equipment. We use top-notch materials and new methods to ensure every project is excellent. Trust us to protect your investments and improve efficiency with great FRP solutions. Contact us today to learn more about how our FRP lamination services can benefit your operations.

Frequently Asked Questions (FAQs)

What types of industries benefit most from FRP lamination?

Industries such as chemical processing, water treatment, and oil & gas benefit greatly from the protective qualities of FRP lamination.

How long does the FRP lamination process take?

The process can take anywhere from a few days to a week, depending on the size and complexity of the project.

Can FRP lamination be applied to any surface?

FRP lamination can be applied to most surfaces, including metal, concrete, and wood, as long as they are properly prepared.

What maintenance is required for FRP laminated surfaces?

Minimal maintenance is required. Regular inspections and cleaning are usually sufficient to ensure longevity.

Is FRP lamination environmentally friendly?

Yes, FRP lamination promotes sustainability by reducing the need for frequent replacements and repairs, thereby conserving resources.

How do I get a quote for FRP lamination services?

For a detailed quote tailored to your specific needs, reach out to Mui Fatt via our website or by contacting our Sales Team via WhatsApp or email at sales@muifatt.com.my.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

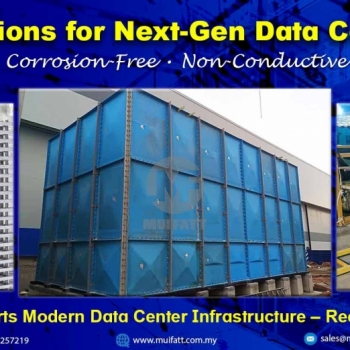

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.