Explore the advantages of upgrading to Mui Fatt Marketing's FRP composite level indicator for your water tank. Learn about its durability, easy installation, and customization options.

Efficient FRP Insights in Wastewater Treatment

13 May 2024

FRP Application in Wastewater Treatment Plants - Resolute Composites

FRP Application in Wastewater Treatment Plants - Resolute Composites

- The Evolution of FRP Technology in Wastewater Treatment

- Rise of FRP Application in Wastewater Treatment Plants

- The Greatest Challenge for Plant Structure

- The Challenges When We Ignore FRP Application in Wastewater Treatment Plants

- The Benefits of Using FRP

- Key Applications of FRP Products in Wastewater Treatment

- Real-World Example: Successful Implementation of FRP in a Wastewater Treatment Plant

- The Future Potential of FRP Technology

- Frequently Asked Questions

The Evolution of FRP Technology in Wastewater Treatment

Over the last few decades, Fiberglass-Reinforced Plastic (FRP) products, known for their strength, durability, and long service life, have become increasingly popular in wastewater treatment plants. This article explores the journey of FRP technology, its impact on wastewater treatment infrastructure, and its future potential.

Rise of FRP Application in Wastewater Treatment Plants

A Historical Overview

The popularity of FRP in wastewater treatment has soared in recent decades. Initially introduced as an alternative to traditional materials like steel and concrete, FRP's versatility, durability, and resistance have led to its widespread adoption across the industry.

The popularity of FRP in wastewater treatment has soared in recent decades. Initially introduced as an alternative to traditional materials like steel and concrete, FRP's versatility, durability, and resistance have led to its widespread adoption across the industry.

Key Factors Driving Adoption

Several factors have contributed to the rapid adoption of FRP technology in wastewater treatment plants. These include its corrosion resistance, lightweight nature, design flexibility, and long-term cost-effectiveness.

The Greatest Challenge for Plant Structure

How Wastewater Plants Operate

Wastewater treatment plants are facilities designed to manage wastewater by removing impurities before releasing it back into the environment. These plants undergo different stages like physical, biological, and chemical treatments to clean the water by getting rid of pollutants.

Structural Considerations

One of the greatest challenges for wastewater treatment plant structure is corrosion. Traditional materials like steel and concrete are susceptible to corrosion in harsh wastewater environments, leading to structural degradation and increased maintenance costs.

FRP as a Solution to Corrosion

FRP's inherent corrosion resistance makes it an ideal solution for addressing the challenges faced by wastewater treatment plants. By choosing FRP materials, plants can ensure long-term structural integrity and minimize the risk of corrosion-related issues.

The Challenges When We Ignore FRP Application in Wastewater Treatment Plants

Challenges without FRP

Wastewater treatment plants that opt for traditional materials such as steel or concrete face several challenges. These include corrosion vulnerabilities, limited lifespan, heavyweight construction, design constraints, and high maintenance requirements.

Material Cost Rises

During the early years, FRP products were up to four times more expensive than conventional materials, making them unaffordable for most places except those with severe corrosion issues.

Over the past few years, FRP product prices have risen more slowly than those of steel, aluminum, and wood. Rising material costs have impacted traditional materials used in wastewater treatment plants, causing increases in wood, steel, and aluminum expenses. This has resulted in higher construction costs and financial limitations for projects at treatment facilities.

Today, while FRP may still have a higher initial cost compared to some traditional materials, the gap has narrowed significantly. Decision-makers in these markets now have the option to select FRP at competitive costs. The long-term cost-effectiveness, due to lower maintenance, durability, and longevity, often makes FRP a preferred choice for many applications, including those that are not necessarily in highly corrosive environments.

The Benefits of Using FRP

In wastewater treatment plants, FRP (fibre-reinforced plastic) is a durable solution that prevents corrosion and wear by replacing steel components. FRP stands out in wet environments for its anti-skid feature, enhancing workplace safety. Common FRP applications include ladders, stairs, walkways, and railings. Visible and low-maintenance, FRP does not require painting or special care.

Advantages of FRP Technology: 10 Reasons to use FRP in Wastewater Treatment Plants

In contrast, the utilization of FRP as a material choice offers numerous benefits for wastewater treatment plants.

|

Material |

Corrosion Resistance |

Longevity |

Weight |

Versatility |

Chemical Resistance |

Maintenance |

Energy Efficiency |

Environmental Impact |

Cost-Effectiveness |

Regulatory Compliance |

|---|---|---|---|---|---|---|---|---|---|---|

|

FRP |

High |

Long lifespan |

Lightweight |

Highly versatile |

Exceptional resistance |

Low maintenance |

Energy-efficient design |

Environmentally friendly |

Cost-effective |

Meets regulatory standards |

|

Steel |

Moderate to low |

Moderate lifespan |

Heavyweight |

Limited versatility |

Susceptible to corrosion |

High maintenance |

High energy consumption |

Environmental impact |

High initial cost |

Meets regulatory standards |

|

Concrete |

Low |

Long lifespan |

Heavyweight |

Limited versatility |

Vulnerable to deterioration |

Moderate maintenance |

Moderate energy consumption |

Environmental impact |

Moderate initial cost |

Meets regulatory standards |

|

Wood |

Low |

Short lifespan |

Moderate to lightweight |

Limited versatility |

Susceptible to rot and decay |

High maintenance |

Moderate energy consumption |

Environmental impact |

Low initial cost |

Meets regulatory standards |

Corrosion Resistance

Corrosion Resistance

- FRP is inherently resistant to corrosion, making it ideal for wastewater treatment environments where exposure to aggressive chemicals and sewage is common.

- Unlike metals such as steel or concrete, FRP does not rust or deteriorate over time when exposed to corrosive substances, ensuring long-term structural integrity.

- Research Study Validation: The water quality professionals at the Water Environment Federation found in their 2006 research study titled “Performance Validation of Shell-Media Biological Odor Control System” that FRP structures and equipment have the potential to be highly effective. This study underscores FRP's robustness and reliability in handling the challenging conditions present in wastewater treatment applications.Good airflow and odor removal efficiencies were shown in more than eight months of sampling. This trial demonstrated that FRP setups have the potential to be a key player in maintaining water quality for the long term.

- Longevity

- The durable nature of FRP materials contributes to their long lifespan.

- Unlike traditional materials that may degrade over time due to corrosion or chemical exposure, FRP remains structurally sound.

- This reduces the need for frequent replacements and minimizes downtime in wastewater treatment operations.

- Lightweight

- FRP is significantly lighter than alternatives like steel or concrete, facilitating easier handling, transportation, and installation.

- This lightweight characteristic simplifies logistics and reduces the need for heavy machinery during construction, resulting in cost and time savings.

- Versatility

- FRP can be molded into virtually any shape or size, allowing for customized solutions tailored to the specific requirements of wastewater treatment processes.

- Whether fabricating tanks or structural components, FRP offers flexibility in design and construction, enabling efficient utilization of space and resources within treatment plants.

- Chemical Resistance

- FRP exhibits exceptional resistance to a wide range of chemicals commonly used in wastewater treatment, including acids, alkalis, and organic solvents.

- This chemical resistance ensures the durability and reliability of FRP components, even in highly corrosive environments, thereby minimizing the risk of leaks, spills, and contamination.

- Low Maintenance

- FRP requires minimal maintenance compared to traditional materials, thanks to its inherent resistance to corrosion, rust, and degradation.

- Routine inspections and cleaning are typically sufficient to ensure the continued performance of FRP components, reducing the need for costly repairs or replacements over time.

- Energy Efficiency

- The lightweight nature of FRP translates to lower energy consumption during installation and operation.

- Reduced weight means less energy is required for the transportation and handling of FRP materials.

- The efficient design of FRP components minimizes energy losses during wastewater treatment processes, contributing to overall energy efficiency in treatment plants.

- Environmental Benefits

- FRP is environmentally friendly and sustainable, contributing to waste reduction and resource conservation in wastewater treatment applications.

- Additionally, the long lifespan of FRP components reduces the frequency of replacements, further reducing the environmental impact of treatment plant operations.

- Cost-Effectiveness

- While the initial cost of FRP materials may be higher than some traditional alternatives, the long-term cost savings associated with reduced maintenance, extended lifespan, and energy efficiency make it a cost-effective choice for wastewater treatment plants.

- Investments in high-quality FRP solutions pay off over time through lower operational expenses and improved reliability.

- Regulatory Compliance

- FRP materials meet stringent regulatory standards for safety, performance, and environmental protection in wastewater treatment applications.

- By using FRP components that comply with industry regulations and standards, treatment plants ensure the safety of workers, protect public health, and minimize the risk of regulatory fines or penalties.

Key Applications of FRP Products in Wastewater Treatment

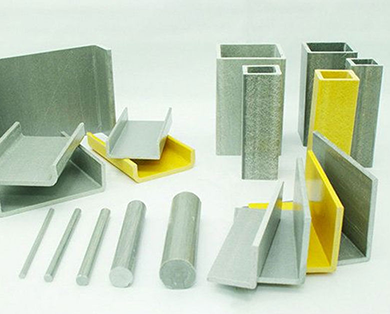

FRP products, including plates, gratings, ladders, handrails, and baffle walls, play a crucial role in wastewater and sewage treatment plants. These structural components are highly valued for their ability to be customized in various sizes and shapes to fit the specific needs of each plant. The use of FRP in these facilities helps ensure efficient and effective treatment processes.

FRP tanks, also known as fiberglass reinforced plastic tanks, offer numerous benefits when it comes to their application in the water treatment industry.

These products, known for their lightweight yet durable nature, are favored by industry owners for their resilience to chemicals and moisture. The ease of manufacturing FRP items further contributes to their popularity in the market.

Real-World Example: Successful Implementation of FRP in a Wastewater Treatment Plant

Case Study: Collaboration with MagSoft

Case Study: Collaboration with MagSoft

As an FRP manufacturer, we have had the privilege of supplying customized FRP tanks to MagSoft, a leading company specializing in customized wastewater treatment plants, for over a year. This partnership has demonstrated the practical benefits and robust performance of FRP in real-world applications.

Project Overview: MagSoft required customized tanks that could withstand the harsh conditions of wastewater treatment processes while offering flexibility in design and ease of installation. Our FRP solutions were chosen for their superior corrosion resistance, durability, and lightweight properties.

Implementation Details:

- Customization: We designed and manufactured FRP tanks tailored to MagSoft's specific requirements, ensuring optimal performance and integration into their wastewater treatment systems.

- Corrosion Resistance: The FRP tanks effectively resisted the corrosive nature of the wastewater, maintaining structural integrity and reducing the need for frequent maintenance.

- Durability: Over the course of the year, the FRP tanks demonstrated exceptional durability, withstanding chemical exposure and environmental stress without any significant degradation.

- Lightweight and Installation: The lightweight nature of FRP made the transportation and installation of the tanks more efficient, saving MagSoft time and reducing labor costs.

Outcomes:

- Enhanced Performance: The FRP tanks contributed to improved operational efficiency at MagSoft's wastewater treatment plants by minimizing downtime and maintenance requirements.

- Cost Savings: The long-term cost savings from reduced maintenance and extended lifespan validated the initial investment in FRP technology.

- Environmental Impact: By opting for FRP tanks, MagSoft benefited from a more sustainable and environmentally friendly solution, aligning with their commitment to eco-friendly practices.

This successful collaboration with MagSoft exemplifies the practical advantages of FRP in wastewater treatment applications, reaffirming its status as a robust and reliable material choice.

The Future Potential of FRP Technology

Shaping the Future

Looking ahead, the future of wastewater treatment lies in the continued advancement and innovation of FRP technology. As sustainability and efficiency become paramount concerns in water treatment facilities, FRP's versatility and performance will continue to drive its adoption and integration into treatment plant infrastructure worldwide.

In conclusion, FRP technology has emerged as a cornerstone of modern wastewater treatment, offering a comprehensive solution to the challenges faced by water treatment facilities. From structural transformation to environmental stewardship, the benefits of FRP extend far beyond traditional materials, paving the way for a more sustainable and efficient future in water management.

Frequently Asked Questions

What makes FRP a suitable material choice for wastewater treatment plants?

FRP is preferred for its strong resistance to rust in tough wastewater settings, lightweight for easier handling and installation, and flexibility to be shaped into different sizes and forms for specific plant needs.

How does FRP compare to other materials such as steel, concrete, and wood in terms of durability and maintenance?

FRP lasts longer and needs less maintenance compared to steel and concrete because it doesn't rust or decay when in contact with corrosive materials. It's also more durable than wood since it doesn't rot.

What are the environmental benefits of using FRP in wastewater treatment plants?

FRP is environmentally friendly and sustainable, contributing to waste reduction and resource conservation. Its long lifespan reduces the frequency of replacements, further minimizing the environmental impact of treatment plant operations.

Are there any challenges associated with using FRP in wastewater treatment plants?

While FRP offers numerous advantages, its initial cost may be higher than some traditional alternatives like steel or concrete. However, the long-term cost savings associated with reduced maintenance, extended lifespan, and energy efficiency make it a cost-effective choice in the long run.

Does FRP technology comply with regulatory standards for safety and environmental protection?

Yes, FRP materials meet stringent regulatory standards for safety, performance, and environmental protection in wastewater treatment applications. Treatment plants ensure the safety of workers and protect public health by using FRP components that comply with industry regulations and standards, minimizing the risk of workplace injuries and regulatory fines or penalties.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions

Discover how fiberglass solutions provide a sustainable and cost-effective method for odor control in Malaysian wastewater treatment plants, ensuring long-term operational efficiency and environmental stewardship.

FRP Panel Water Tanks in Data Center Cooling System

Data centers require robust and efficient cooling systems to maintain optimal performance. Fiberglass-Reinforced Plastic (FRP) panel water tanks play a crucial role in these systems by providing durable and efficient water storage solutions. This article explores the benefits of FRP panel water tanks, their importance in data center cooling, and addresses frequently asked questions.

Upgrade Wetland Infrastructure with Durable FRP Solutions

Explore the wonders of wetlands and learn about the importance of conservation efforts. Discover how Mui Fatt specializes in manufacturing high-quality FRP solutions tailored for wetland infrastructure, ensuring durability, sustainability, and lasting protection for these vital ecosystems.

Corrosion in Wastewater Treatment Plant? Fiberglass Solutions!

Wastewater treatment plants are crucial for public health and environmental preservation in Malaysia. However, corrosion poses a significant threat to these facilities, compromising their effectiveness and longevity. This article delves into the corrosion issues facing Malaysian wastewater treatment plants and examines how fiberglass solutions are revolutionizing infrastructure to combat these challenges.

Exploring Fiberglass as a Superior Alternative to Steel in Malaysia: Pros and Cons

Discover the evolving debate between fiberglass and steel in Malaysia's construction landscape. Amidst the country's challenging climate conditions, understanding the pros and cons of each material is crucial for informed decision-making. Let's delve into the merits and limitations of fiberglass as an alternative to steel, examining its suitability for various applications.