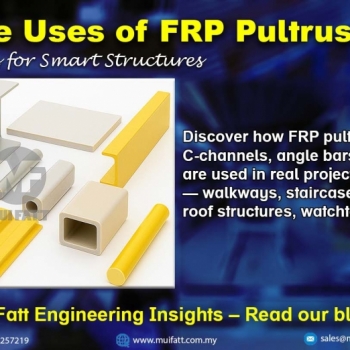

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Upgrade Wetland Infrastructure with Durable FRP Solutions

23 May 2024

Enhance Wetland Infrastructure with Durable FRP Solutions

Enhance Wetland Infrastructure with Durable FRP Solutions

- Discover the Importance of Wetlands

- Common Infrastructure Materials for Wetlands

- Leveraging FRP Expertise for Wetland Solutions

- Areas of Wetlands That Can Leverage FRP Applications

- Frequently Asked Questions

- What is wetland?

- Why are wetlands important?

- What is a Ramsar Site?

- Do Malaysia have Ramsar Sites? Which are those?

- What are the common threats to wetlands?

- How does FRP compare to traditional materials for wetland infrastructure?

- What are the advantages of using FRP in wetland infrastructure?

- Are there any disadvantages to using FRP?

- What types of FRP products are suitable for wetland applications?

- How does FRP contribute to sustainable wetland management?

- Can FRP be customized for specific wetland projects?

Discover the Importance of Wetlands

Wetlands are among the most vital ecosystems on our planet, providing numerous ecological benefits. They act as natural water filters, flood protectors, and habitats for diverse wildlife in hydrology, ponds, and parks. Their beauty, functionality, and technology make them critical to environmental sustainability, hydrology, and biodiversity.

Wetlands are among the most vital ecosystems on our planet, providing numerous ecological benefits. They act as natural water filters, flood protectors, and habitats for diverse wildlife in hydrology, ponds, and parks. Their beauty, functionality, and technology make them critical to environmental sustainability, hydrology, and biodiversity.

Ramsar Sites and Wetland Conservation

Ramsar Sites are wetlands of international importance designated under the Ramsar Convention. These sites are recognized for their ecological significance and are protected to maintain their biodiversity and natural functions. Conserving Ramsar Sites is crucial for preserving global wetland ecosystems. The convention aims to promote the conservation and wise use of wetlands worldwide to ensure their ecological sustainability and the benefits they provide to human societies.

Conservation Challenges Facing by Wetlands

Despite their importance, wetlands face increasing threats from pollution, climate change, and urban development. Preserving these ecosystems requires infrastructure that can withstand harsh environmental conditions. Sustainable management practices are crucial to preserving their integrity.

Common Infrastructure Materials for Wetlands

|

Feature |

FRP |

Wood |

Steel |

Concrete |

|---|---|---|---|---|

|

Durability |

High |

Moderate |

High |

High |

|

Resistance to Corrosion |

Excellent |

Low |

High |

High |

|

Resistance to Rot |

None |

Low |

None |

None |

|

Weight |

Lightweight |

Moderate |

Heavy |

Heavy |

|

Maintenance |

Low |

High |

Moderate |

Moderate |

|

Installation |

Easy |

Moderate |

Moderate |

Difficult |

|

Environmental Impact |

Low |

Moderate |

High |

Moderate |

|

Customizability |

High |

Low |

Moderate |

Low |

|

Cost |

Moderate |

Low |

High |

High |

|

Lifespan |

Long |

Moderate |

Long |

Long |

-

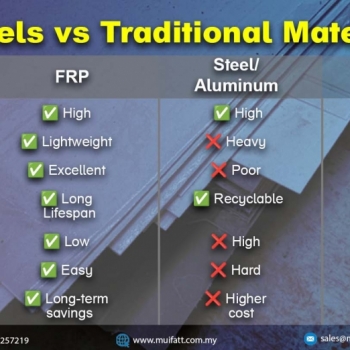

FRP (Fiber Reinforced Polymer):

-

Advantages: High durability, excellent resistance to corrosion and rot, lightweight, low maintenance, eco-friendly, highly customizable, and long lifespan.

-

Disadvantages: Higher initial cost, and potential UV degradation (mitigatable with UV-resistant coatings).

-

-

Wood:

-

Advantages: Natural appearance, initially low cost, and moderate weight.

-

Disadvantages: Susceptible to rot and pests, high maintenance, lower durability, and moderate environmental impact.

-

-

Steel:

-

Advantages: High durability and strength, excellent corrosion resistance with proper treatment, and long lifespan.

-

Disadvantages: Heavy, high cost, requires maintenance to prevent corrosion, and high environmental impact during production.

-

-

Concrete:

-

Advantages: High durability and strength, excellent resistance to environmental conditions, and long lifespan.

-

Disadvantages: Heavy, difficult installation, high cost, moderate environmental impact, and limited customizability.

-

FRP stands out for its combination of durability, corrosion resistance, low maintenance, and customizability, making it a suitable material for wetland infrastructure despite its higher initial cost and production complexity. Wood offers a natural look but requires significant maintenance and has lower durability. Steel and concrete provide high strength and durability but come with higher environmental impacts and costs, as well as more challenging installation processes.

Leveraging FRP Expertise for Wetland Solutions

At Mui Fatt, we specialize in supplying high-quality FRP solutions to diverse industries, including cooling tower companies, wastewater treatment facilities, nature environments, and more. With over 40 years of experience, we ensure our products meet the highest standards of quality and performance.

Trusted FRP solutions

With a portfolio of successful projects across various industries, Mui Fatt is recognized as a trusted leader. Our commitment to excellence and customer satisfaction sets us apart, making us the preferred choice for projects in challenging environments.

Areas of Wetlands That Can Leverage FRP Applications

Our Comprehensive FRP Product Range

Boardwalks and Walkways

-

Our FRP boardwalks and walkways provide safe and stable pathways for visitors to explore wetland areas. Lightweight yet robust, they are resistant to rot, corrosion, and slipping, ensuring long-lasting performance even in challenging conditions.

Observation Towers and Platforms

-

Elevate your wetland with FRP observation towers and platforms. Designed for durability and weather resistance, our structures offer panoramic views of wetland landscapes while blending seamlessly with the natural environment.

Signage and Information Boards

-

Inform and educate visitors with our durable FRP signage and information boards. Weather-resistant and customizable, our products provide essential information about wetland ecosystems, trails, and wildlife conservation efforts.

Fencing and Barriers

-

Protect sensitive wetland habitats with our FRP fencing and barriers. Engineered for strength and longevity, our products help prevent unauthorized access while preserving the integrity of wetland ecosystems.

Customized FRP Solutions

We understand that every wetland project is unique. That's why we offer customized FRP solutions tailored to your specific requirements. Our experienced team works closely with clients to design and manufacture bespoke FRP products that meet their exact needs, from specialized equipment housings to innovative research platforms.

Why Choose Us?

-

Quality Assurance: Our products undergo rigorous quality control to ensure superior performance and reliability

-

Sustainable Practices: We are committed to environmental sustainability, using eco-friendly materials and manufacturing processes

-

Customer Satisfaction: We prioritize customer satisfaction, striving to exceed expectations with our responsive service and timely delivery

Interested in enhancing your wetland infrastructure with durable FRP solutions? Contact us to discuss your project requirements and explore how our expertise can benefit your next wetland project!

Frequently Asked Questions

What is wetland?

A wetland is an area where water covers the soil, either all year or just part of the time. This creates a unique environment with waterlogged soils and diverse plant and animal life. Examples include marshes, swamps, bogs, and fens.

Why are wetlands important?

Wetlands are vital because they maintain biodiversity, filter pollutants, control floods, and store carbon. They provide habitats for many species, support water quality, and offer places for recreation and education.

What is a Ramsar Site?

A Ramsar Site is a wetland recognized for its international importance under the Ramsar Convention. These sites are protected to maintain their biodiversity and natural functions.

Do Malaysia have Ramsar Sites? Which are those?

Yes, Malaysia has several Ramsar Sites. Some of these include Tasek Bera, Pulau Kukup, Sungai Pulai, and the Lower Kinabatangan-Segama Wetlands. These sites are recognized for their ecological importance and are protected to preserve their natural habitats.

What are the common threats to wetlands?

Wetlands are threatened by pollution, climate change, urban development, agricultural runoff, invasive species, and drainage for farming or construction. These threats can lead to habitat loss, lower water quality, and less biodiversity.

How does FRP compare to traditional materials for wetland infrastructure?

FRP (Fiber Reinforced Polymer) is more durable, resistant to corrosion, and low maintenance compared to wood, steel, and concrete. Although it can be more expensive initially, it often saves money in the long run.

What are the advantages of using FRP in wetland infrastructure?

FRP is durable, lightweight, resistant to corrosion, and needs little maintenance. It's also customizable, eco-friendly, and has a long lifespan, making it perfect for wetlands.

Are there any disadvantages to using FRP?

FRP can cost more upfront and might degrade with prolonged UV exposure without the right coatings.

What types of FRP products are suitable for wetland applications?

FRP products for wetlands include boardwalks, observation towers, signs, fences, and custom solutions like equipment housings and research platforms. These products are durable and resistant to environmental conditions.

How does FRP contribute to sustainable wetland management?

FRP helps sustainability by offering long-lasting, low-maintenance solutions that reduce the need for frequent replacements. Its production uses eco-friendly materials and processes, reducing environmental impact.

Can FRP be customized for specific wetland projects?

Yes, FRP can be shaped into various forms to meet the specific needs of different wetland projects. Customization ensures that the infrastructure blends seamlessly with the natural environment and meets project-specific requirements.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

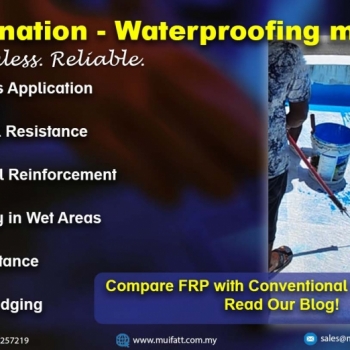

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

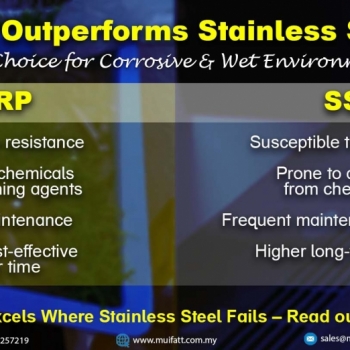

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.