This article explains the polyethylene rotomolding process, compares it with other methods, and helps you decide the best manufacturing approach for your PE product needs.

Rotomolding vs. Injection Molding for Plastic Dustbins: Pros and Cons

09 May 2023

Dustbins play a crucial role in waste management, and selecting the right manufacturing process is essential for creating durable, efficient, and cost-effective solutions.

When it comes to manufacturing plastic dustbins, there are several methods to choose from, but two of the most common methods are rotational molding and injection molding. While both methods are effective for producing high-quality, durable dustbins, they each have their own advantages and disadvantages.

In this article, we’ll delve into the two most popular methods for producing plastic dustbins: rotational molding and injection molding. By comparing their respective strengths and weaknesses, we aim to help you make an informed decision when choosing the right dustbin for your needs.

Why Rotomolding is the Ideal Method for Manufacturing Plastic Dustbins?

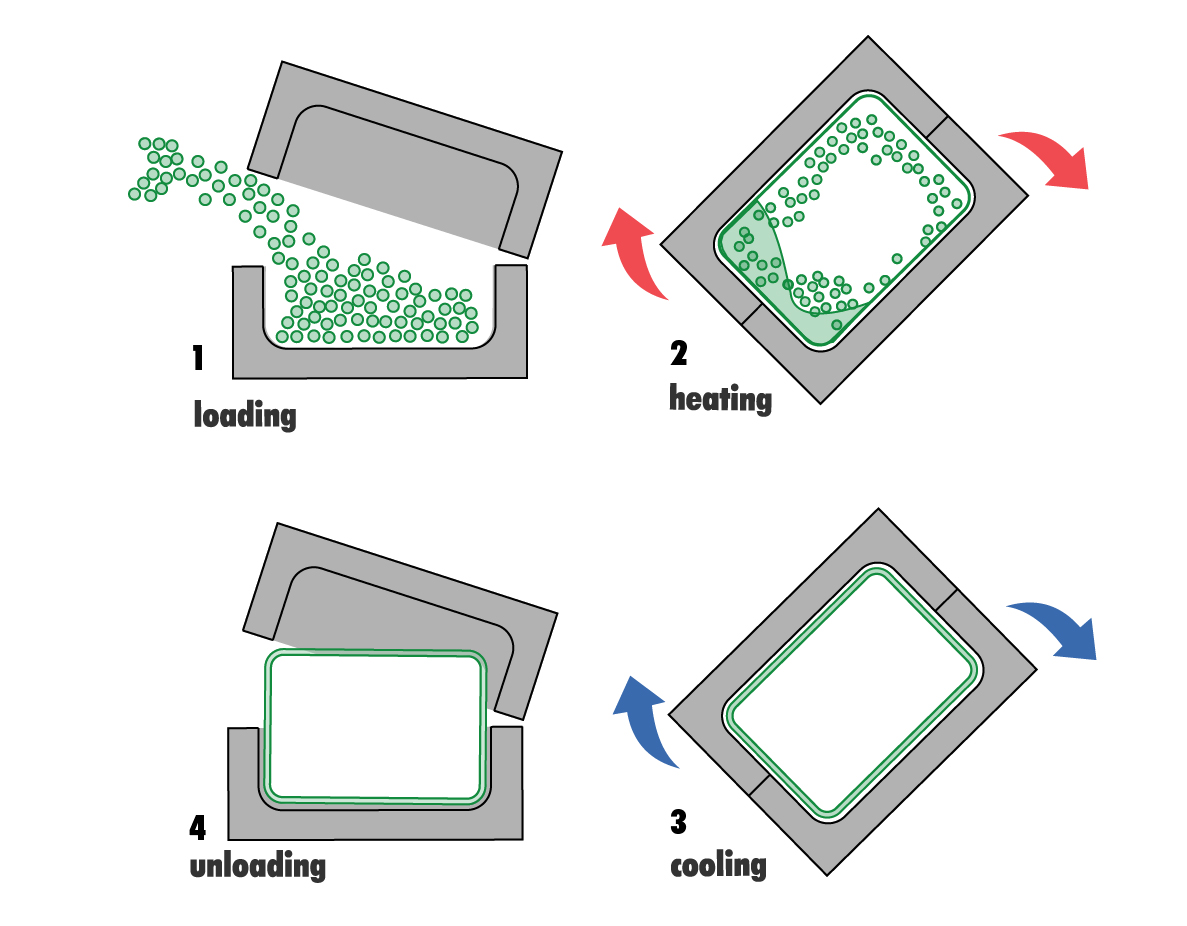

Rotational molding, or rotomolding, is a manufacturing process that involves heating a hollow mold filled with plastic resin and rotating it on two perpendicular axes. This rotation distributes the plastic resin and creates the desired shape. Once the plastic cools and solidifies, the final product is removed from the mold.

Rotational molding, or rotomolding, is a manufacturing process that involves heating a hollow mold filled with plastic resin and rotating it on two perpendicular axes. This rotation distributes the plastic resin and creates the desired shape. Once the plastic cools and solidifies, the final product is removed from the mold.

Rotomolding is known for its ability to produce large, hollow, and complex shapes with consistent wall thickness throughout the part. This makes it a popular method for manufacturing plastic dustbins, water tanks, septic tanks, and playground equipment.

Advantages of Rotomolding for Plastic Dustbins

- Boast seamless construction and even wall thickness, resulting in superior durability and impact resistance

- Accessible for small to medium production runs

- Can produce large, hollow, and complex shapes with consistent wall thickness throughout the part

- Can produce dustbins with intricate designs, curves, and contours

- Can produce dustbins with various features, such as built-in handles or locking mechanisms

- Can use a variety of materials, including recycled plastics

- Low tooling costs compared to injection molding

Disadvantages of Rotomolding for Plastic Dustbins

- Limited to smaller production volumes compared to injection molding

- Longer production cycles compared to injection molding

- Limited to certain types of shapes and sizes

The Pros and Cons of Injection Molding for Plastic Dustbins

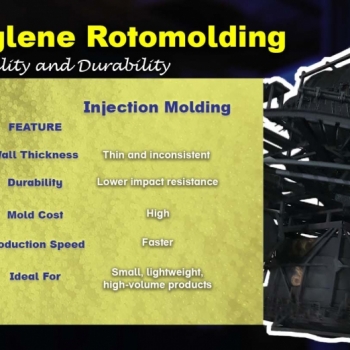

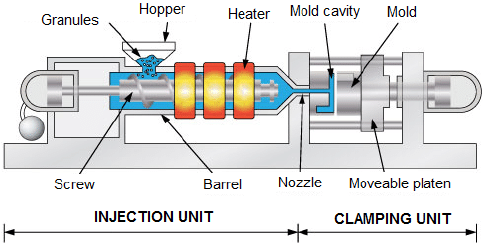

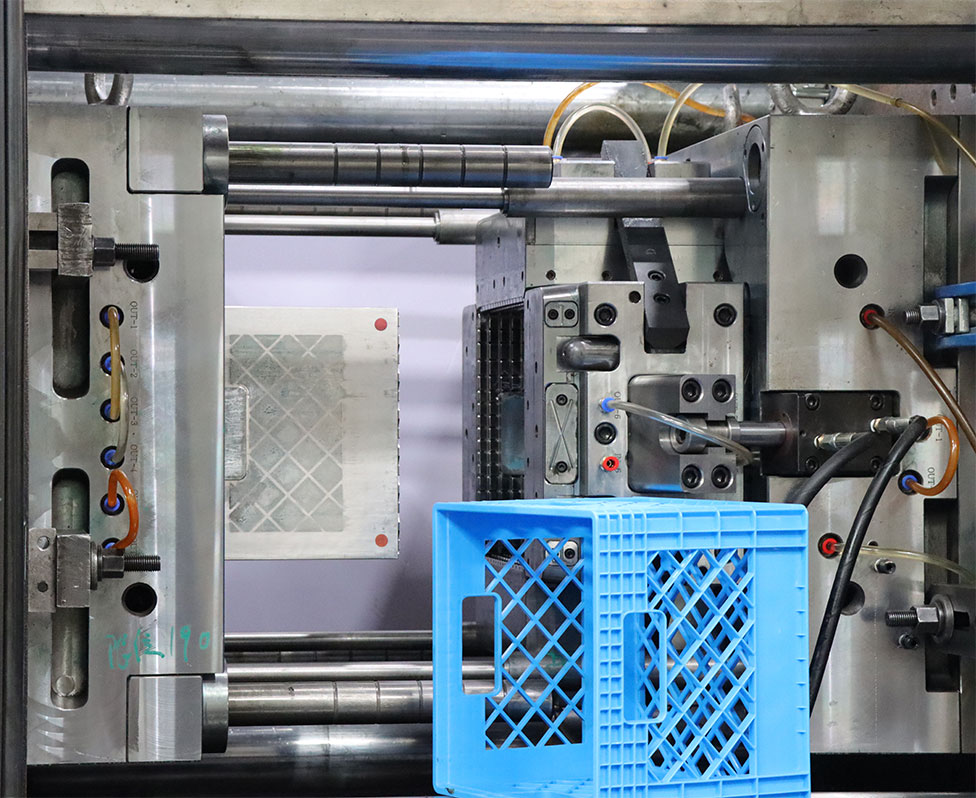

Injection molding is a high-volume production method that involves melting plastic pellets and injecting the molten plastic into a mold cavity. The mold is then cooled and the solidified part is ejected from the mold. This process is highly efficient and allows for mass production of uniform and intricate parts. Injection molding is typically used for parts that have complex geometrics, such as dustbins with curved or rounded shapes.

Injection molding is a high-volume production method that involves melting plastic pellets and injecting the molten plastic into a mold cavity. The mold is then cooled and the solidified part is ejected from the mold. This process is highly efficient and allows for mass production of uniform and intricate parts. Injection molding is typically used for parts that have complex geometrics, such as dustbins with curved or rounded shapes.

Advantages of Injection Molding for Plastic Dustbins

- Can produce high volumes of parts with consistent quality

- Can produce dustbins in a wide range of sizes and colors

- Can produce parts with complex geometries and precise dimensions

- Shorter production cycles compared to rotomolding

Disadvantages of Injection Molding for Plastic Dustbins

- Higher tooling costs compared to rotomolding

- Limited to certain types of shapes and sizes

- Limited flexibility in material choices

- Can sometimes be less durable, especially when subjected to impacts or heavy loads

Choosing the Best Manufacturing Method for Your Plastic Dustbins

Both rotomolding and injection molding are effective methods for producing high-quality, durable plastic dustbins, with their own merits and drawbacks. The choice of manufacturing method will depend on various factors such as the required production volumes, the desired properties of the plastic material, the shape and size of the dustbin, and the available equipment and resources.

Rotational molding offers superior durability, design flexibility, and lower tooling costs, while injection molding is ideal for creating intricate designs and cost-effective solutions for large-scale production.

Ultimately, the choice between these manufacturing methods depends on your specific requirements for durability, design, and budget. By understanding the differences between these two processes, you can make an informed decision and select the best dustbin for your waste management needs.

Looking for more information about trash bins, recycling bins, and dumpsters, or looking to order your own? Contact us today! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – Polyethylene Litter Bins

References:

- Scholarly articles or books on manufacturing processes:

R. J. Crawford, "Plastics Engineering," 3rd Edition, Elsevier, 1998. This book provides comprehensive information on plastic materials and their manufacturing processes, including injection molding and rotational molding.

- Industry publications and trade journals:

- Rotational Molding Magazine (https://rotomolding.org/): This magazine is a valuable resource for news, insights, and research on rotational molding, its applications, and its advantages.

- Plastics Technology Magazine (https://www.ptonline.com/): Plastics Technology covers injection molding, rotational molding, and other plastic processing techniques, providing insights into the latest trends, best practices, and research.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

The Art of Rotomolding: Durable Polyethylene Planter Pots

Discover the manufacturing marvel of rotomolding! Learn why this process ensures durable planter pots and other polyethylene products with exceptional quality.

Are Plastic Flood Barriers the Solution to Malaysia's Flood Crisis?

Flooding in Malaysia is increasingly common. Explore how plastic flood barriers could be a game-changer.

Polyethylene: Recyclability and Sustainability

Understand the recyclability of polyethylene, its minimal environmental impact, and why we prioritize safety in manufacturing eco-friendly PE products.

Scheduled Water Disruption Penang: Essential Tips for Preparation and Resilience

Get essential tips for preparing and staying resilient during scheduled water disruption in Penang. Don't miss out, read more now! #waterdisruptionpenang

A Complete Guide to Brass Float Valves with Copper Balls

Learn how the robust construction of brass and corrosion-resistant properties of copper make these valves ideal for PE water tanks. Discover the benefits, applications, and maintenance tips for ensuring optimal performance in industrial, agricultural, and other settings.

Is Plastic Water Tank Safe?

Is potable water stored in a PE water tank safe to be consumed?