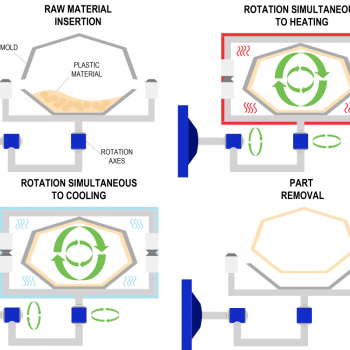

This article explains the polyethylene rotomolding process, compares it with other methods, and helps you decide the best manufacturing approach for your PE product needs.

A Complete Guide to Brass Float Valves with Copper Balls

24 Nov 2023

Brass Float Valves with Copper Balls: A Complete Guide

- Historical Evolution of Float Valves

- Primary Functions and Applications

- Types of Brass Float Valves Compared

- Advantages of Brass Float Valves

- Material Comparison: Brass Versus Alternatives

- Different Sizes of Brass Float Valve: How to choose?

- Installation Guide for Brass Float Valves

- Maintenance Tips for Longevity

- Common Issues and Troubleshooting

- Brass float valve with copper ball

- Conclusion

- FAQs

- What is a heavy-duty brass float valve with a copper ball?

- In what applications are heavy-duty brass float valves with copper balls commonly used?

- Is the copper ball better than other materials for the float in heavy-duty applications?

- Can heavy-duty brass float valves with copper balls be used for potable water?

- What maintenance is required for these valves?

Ball float valves, also known as water level controllers have become indispensable in controlling the flow of liquids across industries. From plumbing to agriculture and manufacturing, these valves offer reliable performance and durability for long-term use.

Ball float valves, also known as water level controllers have become indispensable in controlling the flow of liquids across industries. From plumbing to agriculture and manufacturing, these valves offer reliable performance and durability for long-term use.

With their sturdy construction and resistance to corrosion, brass float valves have gained popularity as a trusted choice for fluid control. The use of brass ensures that these valves can withstand harsh conditions and maintain their functionality over time.

The versatility of brass float valves makes them suitable for a wide range of applications, including water tanks, irrigation systems, and industrial processes. Their ability to regulate liquid levels with precision enhances efficiency and prevents overflow or underfilling.

Historical Evolution of Float Valves

Ancient Origins and Early Designs

Float valves may seem like a modern invention, but their roots can be traced back to ancient civilizations such as Egypt and Greece. These early societies recognized the need for a mechanism that could control the flow of water, and thus began experimenting with various designs.

In ancient Egypt, for example, they developed a simple float valve made from hollowed-out animal horns. These primitive valves were attached to containers or irrigation systems and relied on buoyancy to regulate water levels. Similarly, the Greeks used ceramic vessels with floats made from wood or cork to achieve the same purpose.

Advancements in Functionality

As time went on, civilizations across the world continued to refine and improve upon these early float valve designs. In China during the Tang Dynasty (618-907 AD), for instance, engineers created an innovative float valve known as the "Dragon's Mouth." This device utilized a lever system that opened or closed a valve based on changes in water level.

During the Industrial Revolution in Europe, advancements in manufacturing techniques allowed for more precise and efficient float valves. The introduction of metalworking technologies led to the production of brass float valves, including the use of copper ball, that offered improved durability and reliability compared to their predecessors.

Modern Engineering Techniques

Today, ball float valves have become the standard choice due to their superior performance and longevity. They incorporate advanced engineering techniques that enhance their efficiency and effectiveness in controlling water flow.

One notable feature is their adjustable arm mechanism. This allows users to easily modify the position of the float within a tank or reservoir, thereby regulating water levels according to specific requirements. Modern ball float valves often include built-in filters or screens that prevent debris from entering and clogging the valve mechanism.

Furthermore, manufacturers now utilize computer-aided design (CAD) software and precision machining processes to produce highly accurate components for ball float valves. This ensures tight tolerances are maintained during assembly, resulting in valves that operate smoothly and reliably.

In terms of material selection, brass is favored for its corrosion resistance and durability. It can withstand harsh environmental conditions and remains unaffected by the chemicals commonly found in water systems. This makes brass ball float valves suitable for a wide range of applications, including residential plumbing, agricultural irrigation, industrial processes, and more.

Primary Functions and Applications

Brass float valves play a crucial role in regulating liquid levels, using the principle of buoyancy to automatically open or close. These valves are commonly employed in various settings such as water tanks, toilets, cooling systems, and industrial machinery.

Regulating Liquid Levels with Buoyancy

The primary function of brass float valves is to maintain consistent liquid levels by responding to changes in buoyancy. When the liquid level rises above a certain point, the float attached to the valve rises as well. As the float reaches a predetermined height, it triggers the valve to close, preventing further inflow of liquid. Conversely, when the liquid level drops below a specific threshold, the float descends and opens the valve to allow more liquid into the system.

Versatile Applications in Different Settings

Brass float valves find extensive applications across various industries and everyday scenarios. In water tanks, these valves ensure that the tank remains filled without overflowing or running dry. By controlling water levels effectively, they prevent wastage and ensure a continuous supply for domestic or commercial purposes.

Toilets also rely on brass float valves for efficient water management. When you flush a toilet, water fills up within seconds before stopping at an appropriate level determined by the float valve. This mechanism prevents excessive water usage while still maintaining adequate flushing power.

Cooling systems like air conditioners utilize brass float valves to regulate coolant levels. By monitoring refrigerant levels accurately, these valves help maintain optimal cooling performance while preventing damage caused by low refrigerant levels or overflow.

Industrial machinery often incorporates brass float valves, including copper balls, into their design for fluid control purposes. These machines may require precise liquid levels for smooth operation and safety reasons. Float valves ensure that liquids are maintained at desired levels consistently throughout their operation.

Preventing Overflow and Dry Running Situations

One of the key advantages of brass float valves is their ability to prevent overflow or dry running situations effectively. With their automatic opening and closing mechanism based on buoyancy, these valves ensure that liquid levels stay within desired parameters. This prevents the risk of overflow, which can lead to costly damage or water wastage. By preventing dry running situations, brass float valves protect equipment from damage caused by inadequate lubrication or cooling.

Types of Brass Float Valves Compared

There are different types available that cater to various applications and installation requirements. Let's take a closer look at the two main types: ballcock and diaphragm designs.

Ballcock Design

The ballcock design is one of the most common types of brass float valves. It consists of a hollow metal or plastic ball attached to an arm mechanism. As water fills the tank, the ball rises along with the water level, eventually closing off the valve when it reaches a predetermined height. This design is often used in toilet tanks and other low-pressure applications.

One advantage of the ballcock design is its simplicity. The mechanism is straightforward, consisting of just a few moving parts, making it easy to install and maintain. This type of valve allows for quick and efficient filling of tanks due to its large inlet size.

However, one drawback of ballcock valves is their susceptibility to wear and tear over time. The constant movement of the arm mechanism can lead to mechanical failures, such as leaks or sticking issues. Regular inspection and maintenance are necessary to ensure optimal performance.

Diaphragm Design

The diaphragm design offers an alternative solution for controlling water flow in various applications. Instead of using a floating ball, this type utilizes a flexible rubber diaphragm that moves up and down based on water pressure changes.

One key advantage of diaphragm valves is their ability to handle higher pressure ratings compared to ballcock valves. They are commonly used in industrial settings where higher pressures are involved, such as commercial plumbing systems or irrigation systems.

Another benefit of diaphragm valves is their resistance to corrosion. The rubber diaphragm acts as a barrier between the water and the metallic components, protecting them from potential damage caused by corrosive elements in the fluid being controlled.

However, diaphragm valves may have limitations. Due to the nature of their design, they may not provide as precise control over water levels as ballcock valves. The diaphragm itself can be prone to wear and tear over time, requiring periodic replacement.

Advantages of Brass Float Valves

Excellent Corrosion Resistance

Brass float valves offer excellent corrosion resistance properties, making them a superior choice compared to other materials like plastic or steel. This means that the valves can withstand exposure to harsh environments without deteriorating or losing their functionality. Whether it's in industrial settings or residential applications, the corrosion resistance of brass ensures long-lasting performance and reliability.

High Temperature Tolerance

One of the key advantages of brass float valves is their ability to withstand high temperatures without compromising their structural integrity. This makes them suitable for use in various industries where hot liquids or steam are involved. Unlike plastic valves that may warp or melt under extreme heat, brass valves remain robust and dependable even when exposed to elevated temperatures.

Exceptional Reliability with Minimal Maintenance

Another significant advantage of brass float valves is their exceptional reliability coupled with minimal maintenance requirements. Once installed, these valves work reliably for extended periods without frequent repairs or replacements. The durable nature of brass ensures that the valve components do not wear out easily, reducing the need for constant upkeep. This translates into cost savings and peace of mind for users who can rely on the valve's consistent performance over time.

Brass float valves also require minimal maintenance due to their self-lubricating properties. The natural lubricity of brass reduces friction between moving parts within the valve, preventing excessive wear and tear. As a result, users can enjoy hassle-free operation without worrying about regular lubrication or frequent component replacements.

In addition to these advantages, brass float valves are known for their versatility and compatibility with various fluids and gases. They can be used in a wide range of applications such as water tanks, cooling systems, fuel tanks, and more.

To summarize, brass float valves offer several advantages over other materials like plastic or steel. Their excellent corrosion resistance ensures durability even in harsh environments, while their high temperature tolerance makes them suitable for use in diverse industries. Moreover, these valves provide exceptional reliability with minimal maintenance requirements, making them a cost-effective and dependable choice for various applications.

Material Comparison: Brass Versus Alternatives

Superior Strength and Durability

Brass float valves have a clear advantage over their plastic and stainless steel counterparts. While plastic valves may be more cost-effective, they lack the longevity that brass provides. Over time, plastic can become brittle and prone to cracking or breaking under pressure, which can lead to leaks or malfunctions. On the other hand, brass is known for its robustness and ability to withstand high pressure without compromising its structural integrity.

Affordability vs Longevity

When considering the choice between brass, plastic, and stainless steel float valves, affordability is often a key factor. Plastic valves are typically the most budget-friendly option upfront. However, it's important to weigh this against the long-term costs of potential replacements due to wear and tear. Brass float valves may come with a higher price tag initially but offer exceptional durability that can save you money in the long run by minimizing maintenance needs and replacement expenses.

Corrosion Resistance

Stainless steel is renowned for its resistance to corrosion, making it an attractive alternative to brass in certain applications. However, it's essential to consider whether this level of corrosion resistance is necessary for your specific needs. In some cases, such as in water tanks or plumbing systems that do not contain corrosive substances, brass may provide sufficient protection against corrosion while being more affordable than stainless steel options.

Different Sizes of Brass Float Valve: How to choose?

There are different sizes available in the market. Choosing the right size is crucial for optimal performance and efficiency. Let's explore the factors you need to consider when selecting a brass float valve size.

Factors to consider when choosing a brass float valve size for reviews.

- Tank Capacity: The first factor to consider is the capacity of your tank. A larger tank will require a larger brass float valve to ensure proper water flow regulation. On the other hand, a smaller tank may only need a smaller-sized valve.

- Water Flow Rate: Another important consideration is the desired water flow rate. If you need a high water flow rate, such as for industrial applications, you will likely require a larger-sized brass float valve that can accommodate this demand.

- Pressure Requirements: Different applications have varying pressure requirements. It's essential to choose a brass float valve size that can handle the specific pressure levels needed for your system. Failure to select an appropriate size could result in leaks or inadequate performance.

- Float Size: The size of the float itself plays a role in determining the ideal brass float valve size. A larger float will require a bigger valve opening for smooth operation and accurate control of water levels.

- Space Constraints: Consider the available space where you plan to install the brass float valve. Ensure that there is enough room for proper installation and maintenance without any restrictions or obstructions.

- Compatibility with Existing System: If you're replacing an existing brass float valve, ensure that you choose a size compatible with your current system's fittings and connections.

Importance of Selecting the Right Size for Optimal Performance

Selecting the right-size brass float valve is essential for achieving optimal performance and longevity of your system:

- Efficient Water Control: Choosing an appropriately sized brass float valve ensures efficient control over water levels. It allows for accurate regulation, preventing overflows or inadequate filling.

- Prevention of Water Wastage: A properly sized brass float valve helps in preventing water wastage by maintaining the desired water level without unnecessary overflow or leakage.

- Extended Lifespan: When you choose the right size, the brass float valve operates within its intended capacity.

Installation Guide for Brass Float Valves

To ensure a successful installation of your brass float valve, there are a few key steps you need to follow. By shutting off the water supply and aligning the valve properly, you can prevent leaks and ensure optimal performance.

Shut Off the Water Supply

Before installing your brass float valve, it's crucial to shut off the water supply. This step is essential to prevent any accidents or damage during the installation process. Locate the main water shutoff valve in your plumbing system and turn it off completely. This will stop the flow of water and allow you to work safely.

Proper Alignment with Plumbing System

Once you have turned off the water supply, it's time to install the brass float valve securely in place. One important aspect of this installation is ensuring proper alignment between the valve inlet/outlet ports and your plumbing system.

Carefully examine your plumbing system and identify where the brass float valve needs to be installed. Ensure that there is enough space for the valve to fit comfortably without any obstructions. Aligning these ports correctly will allow for smooth water flow and prevent any leaks or disruptions.

Test for Leaks

After installing the brass float valve, it's crucial to test it for leaks before turning on the water supply again. Even a small leak can cause significant damage if left unnoticed.

Turn on the water supply gradually while keeping an eye on all connections around the brass float valve. Look for any signs of dripping or moisture buildup. If you notice any leaks, tighten the connections appropriately until they are secure.

Adjust Float Arm or Mechanism

The last step in installing a brass float valve is adjusting its float arm or mechanism if necessary. The purpose of this adjustment is to control when and how much water enters or exits the tank being regulated by the valve.

If you find that your tank isn't filling up enough or overflowing, you may need to adjust either the float arm or the mechanism. Follow the manufacturer's instructions for your specific brass float valve model to make these adjustments.

By ensuring that the float arm or mechanism is properly adjusted, you can maintain the desired water level in your tank and prevent any potential issues.

Maintenance Tips for Longevity

Regularly inspect the brass float valve to ensure its longevity. Look out for signs of wear, corrosion, or damage that may affect its performance. It's essential to catch any issues early on to prevent further damage and costly repairs.

Inspect for Wear, Corrosion, or Damage

Take a close look at the brass float valve and check for any visible signs of wear, corrosion, or damage. Look out for rust spots, cracks, or dents that could compromise its functionality. If you notice any issues, it's crucial to address them promptly.

Clean Out Debris and Sediment Buildup

Over time, debris and sediment can accumulate in the brass float valve. This buildup can hinder its proper functioning and lead to leaks or blockages. Regular cleaning is necessary to keep the valve in optimal condition.

To clean the valve:

- Shut off the water supply.

- Disconnect the valve from the water source.

- Remove any screws or clips holding the valve together.

- Carefully remove any debris or sediment using a soft brush or cloth.

- Rinse the valve thoroughly with clean water.

- Reassemble and reinstall the valve.

Regular cleaning will help maintain smooth operation and prevent clogs that could impact water flow.

Lubricate Moving Parts as Needed

To ensure smooth operation and prevent sticking, it's important to lubricate the moving parts of your brass float valve regularly. Lubrication reduces friction between components, allowing them to move freely without resistance.

Here's how you can lubricate your brass float valve:

- Turn off the water supply.

- Disassemble the valve if necessary (refer to manufacturer instructions).

- Apply a small amount of silicone-based lubricant onto moving parts such as hinges or pivots.

- Avoid using petroleum-based lubricants as they may degrade certain materials used in valves.

- Reassemble the valve and turn on the water supply.

Regular lubrication will help extend the lifespan of your brass float valve and ensure its proper functioning.

By following these maintenance tips, you can keep your brass float valve in excellent condition for years to come. Regular inspections, cleaning out debris, and lubricating moving parts are essential for maintaining optimal performance.

Common Issues and Troubleshooting

Obstructions or Misalignment

If you find that your brass float valve fails to shut off completely, it's essential to check for any obstructions or misalignment. Sometimes, debris or sediment can get stuck in the valve, preventing it from closing properly. In such cases, a thorough cleaning of the valve may be necessary. Ensure that the float arm is correctly aligned with the valve body. Misalignment can cause the float arm to interfere with the valve's closing mechanism, resulting in incomplete shut-off.

Faulty Float Arm Adjustment or Clogged Inlet Filters

Inadequate water flow through your brass float valve can be attributed to a faulty float arm adjustment or clogged inlet filters. The float arm should be properly adjusted so that it allows enough water into the tank while maintaining the correct water level. If the adjustment is incorrect, it can restrict water flow and affect the performance of the valve. Clogged inlet filters can impede water flow into the valve, leading to reduced functionality. Regularly inspect and clean these filters to ensure optimal performance.

Worn-out Seals or Damaged Components

Leaking from the valve body is a common issue that may indicate worn-out seals or damaged components within the brass float valve. Over time, seals can deteriorate due to constant exposure to water and other elements. This deterioration compromises their ability to create a watertight seal, resulting in leaks. Similarly, damaged components such as valves or gaskets can also contribute to leaks in the system. If you notice any signs of leakage from your brass float valve, it's crucial to inspect and replace any worn-out seals or damaged components promptly.

Troubleshooting issues with your brass float valve requires careful observation and attention to detail. By checking for obstructions or misalignment, ensuring proper adjustment of the float arm and cleanliness of inlet filters, as well as addressing any leaking from the valve body, you can effectively troubleshoot common problems. Regular maintenance and timely repairs are crucial to maintaining the functionality of your brass float valve and preventing further issues down the line.

Remember, if you're unsure about how to troubleshoot or repair your brass float valve, it's always best to consult a professional plumber or technician who can provide expert guidance and assistance.

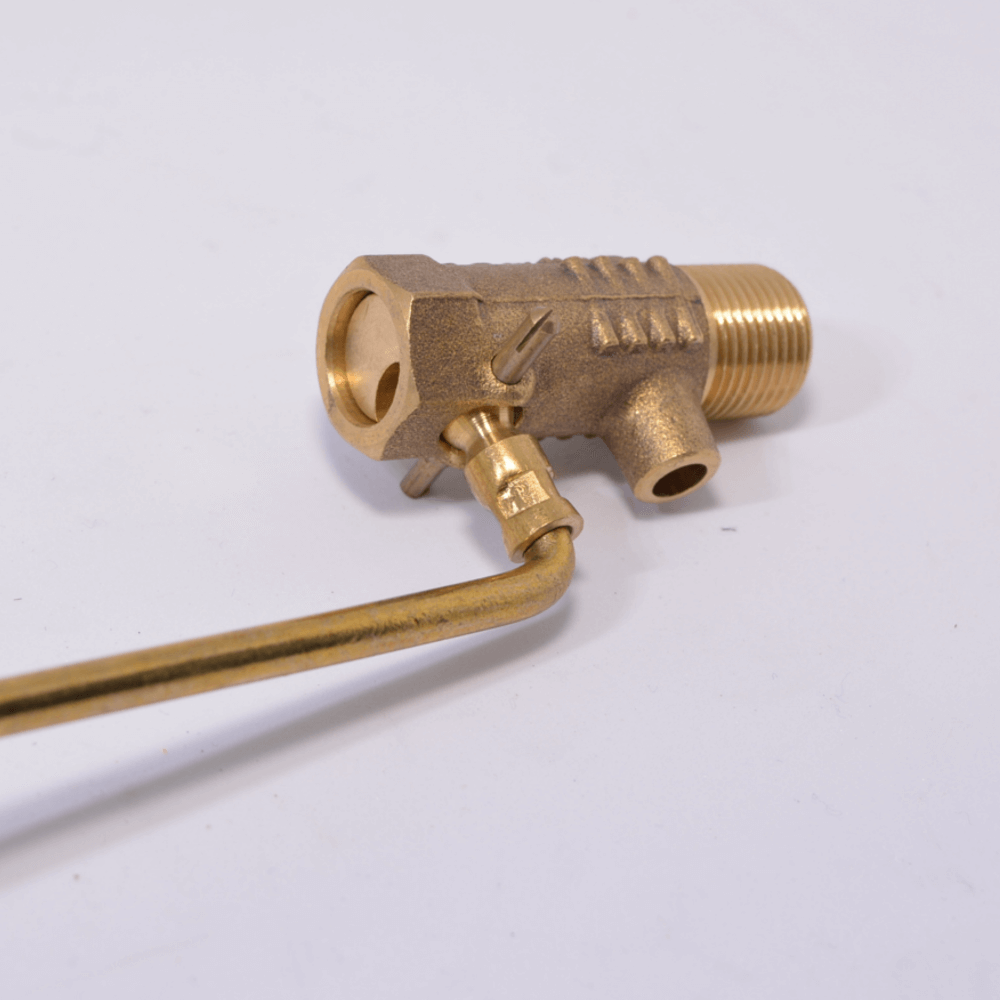

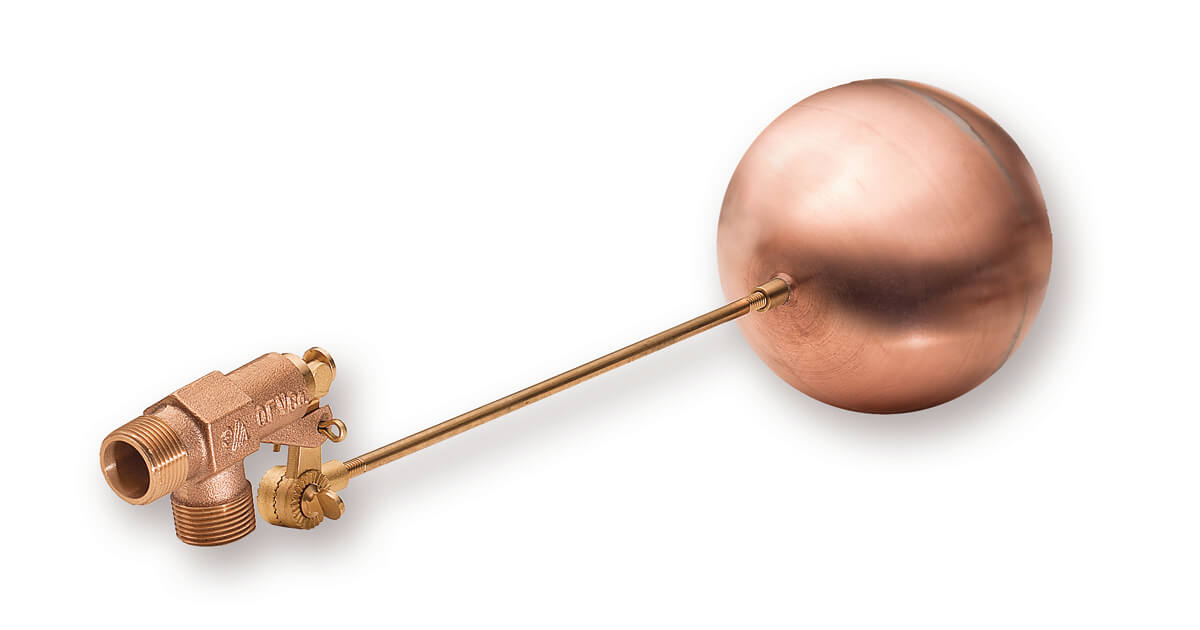

Brass float valve with copper ball

A brass float valve with a copper ball is a reliable and durable product that gets the job done. This high-quality brass ball float valve ensures efficient performance and long-lasting usage.

Material Comparison for float ball: Copper Versus Alternatives

So, we've talked about why float valves are important and how they work. Now let's dive into the different materials used for float balls. One popular option is copper, which is known for its durability and resistance to corrosion. But there are also alternative materials that can be used, like plastic or stainless steel. Plastic float balls are lightweight and affordable, but they may not be as strong as copper. On the other hand, stainless steel float balls are incredibly strong and long-lasting, but they can be more expensive. So, when choosing a float ball material, it's important to consider factors like durability, cost, and the specific needs of your application.

|

Material |

Price |

Durability |

Application |

Suitable fo |

Benefits |

|---|---|---|---|---|---|

|

Copper |

Moderate |

High |

General |

Plumbing, water tanks |

Durable, corrosion-resistant |

|

Plastic |

Low |

Low |

General |

Residential, small-scale |

Lightweight, affordable |

|

Stainless Steel |

High |

Very High |

Heavy-duty |

Industrial, commercial |

Strong, long-lasting, corrosion-resistant |

Benefits of Copper Ball

The copper ball in brass float valves plays a crucial role in ensuring reliable performance. The use of copper as the material for the ball offers several advantages over other materials.

Firstly, copper is known for its excellent corrosion resistance properties. It can withstand exposure to water and various chemicals without deteriorating or losing its effectiveness. This makes it highly suitable for use in clean water applications where maintaining water quality is essential.

Copper has excellent thermal conductivity properties. This means that it can quickly adjust to changes in temperature, allowing the valve to respond promptly to fluctuations in water levels. As a result, the brass float valve with a copper ball can accurately control the flow of water and maintain consistent levels.

Moreover, copper is an antimicrobial material, meaning it has natural properties that inhibit the growth of bacteria and other microorganisms. In applications where hygiene is vital, such as drinking water systems or food processing facilities, using a brass float valve with a copper ball helps ensure clean and safe water supply.

Furthermore, copper balls are known for their durability and longevity. They are resistant to wear and tear caused by continuous usage and exposure to heavy duty harsh conditions. This makes them ideal for heavy duty applications where reliability is paramount.

Float valves of various sizes require different sizes of copper balls

Different sizes of copper balls are required for different float valves. These small round objects help regulate the water level in tanks. It's fascinating how they function. The size of the valve determines the appropriate size of the copper ball. If a large ball is used in a small valve, it won't fit properly and won't function correctly. Conversely, if a small ball is used in a large valve, it may struggle to control the water level effectively. Therefore, it's crucial to match the size of the copper ball with the size of the float valve.

Conclusion

So, there you have it! We've explored the world of brass float valves, from their historical evolution to their primary functions and advantages. We've compared different types of brass float valves and discussed how to choose the right size for your application. We've even provided an installation guide and maintenance tips to ensure longevity.

Now armed with this knowledge, it's time for you to take action. Whether you need a brass float valve for your plumbing system or industrial equipment, make an informed decision based on your specific needs. Remember to consider the advantages of brass, such as its durability and corrosion resistance. And don't forget to regularly maintain your valve to prolong its lifespan.

So go ahead and confidently select the perfect brass float valve for your project. With this versatile and reliable component, you can ensure efficient fluid control and peace of mind. Happy valve hunting!

Contact us today via WhatsApp or email – sales@muifatt.com.my to learn more about our PE Tank

FAQs

What is a heavy-duty brass float valve with a copper ball?

A heavy-duty brass float valve with a copper ball is a robust and reliable valve used to control the flow of liquid in various applications. It consists of a durable brass body and a copper ball that floats on the liquid's surface, regulating the valve's opening and closing.

In what applications are heavy-duty brass float valves with copper balls commonly used?

Heavy-duty brass float valves with copper balls are commonly used in industrial settings such as water tanks, boilers, cooling towers, and irrigation systems. They are also found in commercial applications like automatic filling mechanisms for livestock troughs or high-pressure water systems that utilize PE Tanks.

Is the copper ball better than other materials for the float in heavy-duty applications?

Yes, using a copper ball as the float in heavy-duty applications offers several advantages. Copper is resistant to corrosion, ensuring longevity even when exposed to harsh conditions or different types of liquids. Its density allows for precise control over the valve's opening and closing.

Can heavy-duty brass float valves with copper balls be used for potable water?

Absolutely! Heavy-duty brass float valves with copper balls can be safely used for potable water systems. The combination of durable brass construction and corrosion-resistant copper ensures that the water remains uncontaminated while maintaining reliable flow regulation.

What maintenance is required for these valves?

To keep heavy-duty brass float valves with copper balls functioning optimally, regular maintenance is crucial. This includes periodic inspections to check for any signs of wear or damage, cleaning debris from the valve body, lubricating moving parts if necessary, and replacing worn-out components as needed.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

The Art of Rotomolding: Durable Polyethylene Planter Pots

Discover the manufacturing marvel of rotomolding! Learn why this process ensures durable planter pots and other polyethylene products with exceptional quality.

Are Plastic Flood Barriers the Solution to Malaysia's Flood Crisis?

Flooding in Malaysia is increasingly common. Explore how plastic flood barriers could be a game-changer.

Polyethylene: Recyclability and Sustainability

Understand the recyclability of polyethylene, its minimal environmental impact, and why we prioritize safety in manufacturing eco-friendly PE products.

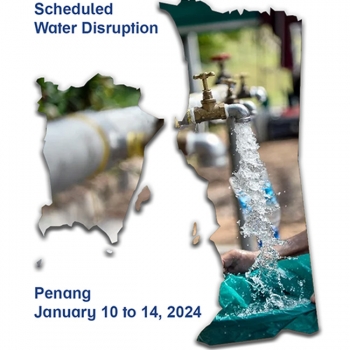

Scheduled Water Disruption Penang: Essential Tips for Preparation and Resilience

Get essential tips for preparing and staying resilient during scheduled water disruption in Penang. Don't miss out, read more now! #waterdisruptionpenang

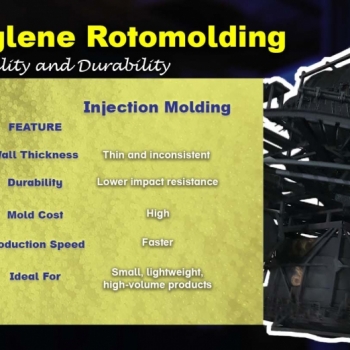

Rotomolding vs. Injection Molding for Plastic Dustbins: Pros and Cons

Rotomolding and injection molding are two common methods used for manufacturing plastic dustbins. This article compares the pros and cons of each method to help you decide which is right for your needs

Is Plastic Water Tank Safe?

Is potable water stored in a PE water tank safe to be consumed?