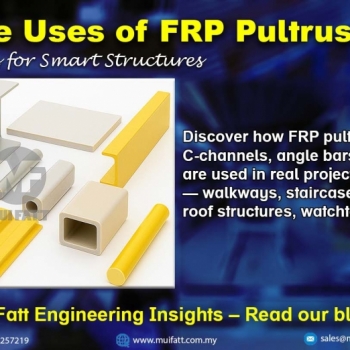

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Fixed Ladders: Understanding OSHA Safety & Customization

06 Feb 2024

Fixed Ladders: Understanding OSHA Safety & Customization

Fixed Ladders: Understanding OSHA Safety & Customization

- Understanding Fixed Ladders

- OSHA Safety Requirements

- Customization of Fixed Ladders

- Fall Protection Systems

- Safety Measures for Climbing

- Maintenance and Inspection

- Importance of Compliance and Customization

- Advanced Safety Features

- Closing Thoughts

- Frequently Asked Questions

- What are the key features of fixed ladders that ensure safety?

- How can customization of fixed ladders enhance workplace safety?

- Why is compliance with OSHA regulations crucial for using fixed ladders?

- What maintenance practices should be followed to keep fixed ladders in optimal condition?

- How do fall protection systems incorporated into fixed ladders contribute to workplace safety?

Fixed ladders, commonly known as cat ladders or monkey ladders, play a crucial role in various settings. These vertical structures provide safe access to elevated areas and are often equipped with safety cages for added protection and compliance with regulations. Cat ladders are commonly found in industrial or commercial settings, designed for workplace safety and access.

Dating back to ancient times, fixed ladders have been essential tools in human civilization, aiding individuals in reaching heights otherwise unattainable. Whether used in industrial facilities or residential buildings, these ladders serve as reliable means of vertical transportation.

Understanding the significance and design considerations of fixed ladders is vital for ensuring safety and compliance with regulations.

Understanding Fixed Ladders

Safety Standards

Fixed ladders in construction adhere to safety standards for side rails and guardrails, ensuring worker safety. The ladder's corrosion-resistant materials protect against damage over time, while slip-resistant surfaces prevent slips and falls. To maintain safe connection points, fixed ladders must have openings at the upper level for equivalent ladder attachment.

-

Safety standards prioritize side rails and guardrails

-

Corrosion-resistant materials ensure durability

-

Slip-resistant surfaces prevent accidents

-

Openings at the upper level allow secure connections

Components of fixed ladders encompass surface, construction, connection, and load factors. Slip-resistant ladder surfaces are vital for user safety, while sturdy construction materials guarantee long-term durability. Properly connecting ladder components is crucial to avoid accidents on-site.

-

Components include surface, construction, connection, and load

-

Slip-resistant surfaces enhance user safety

-

Sturdy construction ensures durability

-

Secure component connections prevent accidents

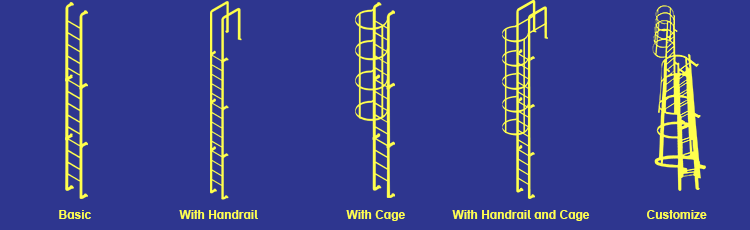

Let's discuss the various kinds of fixed ladders and where they are best used:

-

Fixed Ladder (Basic) - Suitable for straightforward access to elevated areas

-

Fixed Ladder with Handrail - If additional support is required, a fixed ladder with a handrail provides extra stability

-

Fixed Ladder with Cage - For higher structures, a fixed ladder with a cage can prevent falls and ensure safe ascent and descent

-

Fixed Ladder with Handrail and Cage - Combining a handrail and cage on a fixed ladder offers the highest level of protection

-

Customizable Fixed Ladder - tailored to specific application requirements, ensuring optimal safety for workers in various environments

Whether it's for industrial facilities, construction sites, or warehouses, choosing the right type of fixed ladder is crucial for maintaining safety standards and preventing accidents.

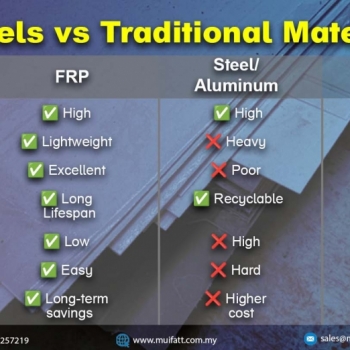

Materials

Fixed ladders can be constructed from steel, stainless steel, fiberglass reinforced plastic (FRP), or aluminum based on factors like weight and cost considerations. Choosing the right material guarantees longevity and reliability of fixed ladders in various environments.

-

Steel offers strength but may be heavy

-

Stainless steel resists corrosion well

-

Aluminum is lightweight yet robust

-

Fiberglass Reinforced Plastic is strong but light, doesn't rust, needs little upkeep, and tough.

Material choice impacts durability

|

Material |

Price |

Durability |

Maintenance Cost |

Advantages |

|---|---|---|---|---|

|

Steel |

$$ |

High |

High |

Strong, durable |

|

Stainless Steel |

$$$ |

High |

Medium |

Corrosion-resistant, aesthetically pleasing |

|

Aluminum |

$$ |

Medium |

High |

Lightweight, corrosion-resistant |

|

Fiberglass Reinforced Plastic |

$$ |

High |

Low |

Corrosion-resistant, lightweight, customizable, various color |

Vertical access features in fixed ladders provide a safe way to reach higher levels efficiently with stable side rails preventing falls off the sides of the ladder structure. The opening width between side rails should allow easy passage without compromising user safety.

OSHA Safety Requirements

Fall Protection

Fall protection is vital. Installing guardrails on both sides of the ladder enhances safety by providing additional protection against falls. Corrosion can weaken the ladder's structure, increasing the risk of accidents. Ensuring a proper connection between the ladder and upper level is crucial to prevent any hazardous openings or gaps.

Guardrails are an indispensable safety feature for fixed ladders, offering protection to users by preventing falls off edges. Side rails on guardrails play a significant role in reducing accident risks by keeping ladder users safe. It is essential for fixed ladders to have guardrails on both sides, ensuring employee and construction worker safety. Guardrails extending above the surface opening provide a secure handhold for users, further enhancing safety measures.

Safety Gates

Safety gates play a crucial role in preventing falls from fixed ladders' sides or edges, acting as protective barriers similar to guardrails. These gates ensure there are no risky openings or gaps along the ladder's surface, promoting user safety significantly. Construction sites and industrial service areas often require installation of safety gates on fixed ladders to adhere to strict safety regulations. The easy connection of safety gates with side rails provides a secure barrier that enhances user protection while climbing.

Compliance

Compliance with ladder safety regulations is paramount in minimizing accidents and ensuring employee well-being when using fixed ladders. Constructing fixed ladders with a minimum width between side rails ensures stability during climbing activities; this stable surface reduces fall risks significantly. Secure connections between ladder sections designed to withstand applied loads are essential for overall structural integrity and user security.

Customization of Fixed Ladders

Fixed ladders can be customized to suit specific construction needs, such as adjusting the width or adding side rails and guardrails for enhanced safety. Extending fixed ladders is essential to reach upper levels or service areas safely. A secure connection between the ladder and the structure is crucial in reducing accidents.

Fixed ladders can be customized to suit specific construction needs, such as adjusting the width or adding side rails and guardrails for enhanced safety. Extending fixed ladders is essential to reach upper levels or service areas safely. A secure connection between the ladder and the structure is crucial in reducing accidents.

Custom features of fixed ladders are vital for user safety and convenience. Side rails that extend along the entire length provide a secure surface, while guardrails minimize fall risks. These customizable options ensure that fixed ladders meet the unique requirements of homes and businesses.

Importance

Fixed ladders are indispensable for safe access to elevated areas, enabling workers to perform tasks efficiently. Recognizing their significance fosters a culture of workplace safety, prioritizing employee well-being and operational effectiveness.

Compliance with ladder safety regulations is paramount in minimizing accidents and ensuring employee security. Constructing fixed ladders with corrosion-resistant materials maintains structural integrity over time. Adhering to specific width measurements and weight capacities guarantees stability during use.

Compliance

Adhering to ladder safety regulations minimizes accident risks by ensuring employee safety through sturdy construction materials.

- Width: Between 12-16 inches

- Load capacity: At least 250 pounds

-

Corrosion resistance ensures long-term durability

-

Proper design prevents falls

Custom Features

Customized features on fixed ladders enhance user convenience by providing added safety measures like extended side rails throughout the ladder's length.

-

Side Rails: Extend full length for secure climbing

-

Guardrails: Minimize fall risk

-

Safety Cage: Shield that adds an extra layer of protection

Fall Protection Systems

Vertical Ladders

Fixed ladders are vertical structures essential for ascending or descending heights, commonly attached to walls, equipment, or structures for stability. These ladders offer a straightforward solution for vertical access requirements in various settings such as construction sites or industrial facilities. By providing a secure means of climbing to elevated areas, fixed ladders ensure worker safety and efficiency during tasks that involve height differences.

Vertical ladders play a crucial role in ensuring safe access to different levels within buildings or outdoor spaces. Whether it's reaching the roof of a building for maintenance purposes or accessing upper storage areas in warehouses, fixed ladders with proper side rails and rungs facilitate safe movement up and down these vertical structures. The stability offered by ladder connections is vital in preventing accidents and injuries related to falls while using these structures.

Rooftop Guardrails

Rooftop guardrails serve as indispensable safety features associated with fixed ladders, offering protection along the sides and edges of elevated surfaces. These guardrails effectively reduce the risk of falls by creating a physical barrier between workers and potential hazards on the ground or at upper levels. By extending above the ladder's surface, guardrail sides provide added stability during ascent or descent on fixed ladders.

The use of corrosion-resistant materials, such as Fiberglass Reinforced Plastic (FRP) in constructing rooftop guardrails ensures their longevity and durability even when exposed to harsh environmental conditions like inclement weather. This feature enhances workplace safety by maintaining the structural integrity of guardrails over time despite external factors that could compromise their effectiveness.

Safety Measures for Climbing

Basic Introduction

Fixed ladders are a common sight in various settings, from construction sites to residential buildings. These ladders are permanently attached and provide a vertical connection between different levels. Typically equipped with side rails and rungs, fixed ladders ensure safe access for users moving from the ground to an upper level.

Side rails and guardrails play a crucial role in preventing falls. The spacing of rungs should not exceed 12 inches apart, ensuring safe climbing without the risk of slipping or tripping. Regular inspection and maintenance routines are vital to detect any signs of corrosion or damage that could compromise ladder safety over time.

Climbing Procedures

Proper climbing procedures are essential when using fixed ladders to prevent accidents and ensure user safety. Maintaining three points of contact while ascending or descending is key – this means always having two hands and one foot or two feet and one hand on the ladder at all times. Utilizing side rails and guardrails provides stability during climbs, reducing the risk of falls significantly.

Being cautious around openings at upper levels is paramount before starting your climb. Ensuring these areas are clear can prevent unexpected hazards that may pose risks while ascending or descending fixed ladders safely.

Maintenance and Inspection

Regular maintenance and inspection of fixed ladders play a critical role in ensuring the safety of employees who use them. Construction materials like corrosion-resistant Fiberglass Reinforced Plastic (FRP) are essential for the surfaces and connections of fixed ladders to maintain their durability over time. Guardrails positioned on both sides of the ladder opening provide additional protection against falls, reducing the risk of accidents significantly.

Employees need to be trained to recognize any indications of wear or damage on fixed ladders during routine checks. Conducting regular inspections is vital as it helps identify signs of wear and tear early on, such as loose bolts, damaged rungs, or bent rails that could compromise ladder reliability. These checks contribute to preventing potential incidents related to ladder safety by addressing issues promptly.

Regular Checks

-

Regular checks help detect signs of wear like loose bolts.

-

Identifying damaged rungs ensures ladder reliability.

-

Early detection through checks prevents ladder-related incidents effectively.

Safety Compliance

Maintaining safety compliance with fixed ladders is paramount due to their inherent risks for employees using them. Side rails and guardrails serve as crucial components that enhance user safety when climbing fixed ladders. Ensuring these elements are intact through regular service and inspection is necessary to spot any hazards promptly.

Corrosion present on the surface can weaken fixed ladders, jeopardizing their structural integrity over time if not addressed proactively. Therefore, conducting frequent inspections becomes imperative in identifying any potential issues that may compromise employee safety while using fixed ladders.

Fall Protection Devices

-

Harnesses or lifelines offer additional fall protection.

-

Using these devices enhances overall worker safety at heights.

-

Employing appropriate fall protection measures improves ladder safety significantly.

Structural Integrity

Ensuring the structural integrity of fixed ladders is fundamental for safe usage within various settings. By performing regular maintenance activities coupled with thorough inspections, weaknesses in structure can be identified promptly before they escalate into accidents endangering workers' well-being.

Importance of Compliance and Customization

Ensuring compliance with safety regulations is crucial. By meeting these standards, the risk of accidents can be minimized, promoting employee well-being. Customizing fixed ladders to specific construction requirements and user needs is equally important for optimal functionality.

Properly designed fixed ladders incorporate side rails and guardrails, providing a secure connection between upper levels and lower surfaces. It's essential to consider the width and opening of fixed ladders carefully. This ensures that users can navigate them safely while accommodating different individuals' needs.

OSHA Requirements

OSHA (Occupational Safety and Health Administration) has set specific guidelines for fixed ladders to maintain a safe work environment. Adhering to these regulations is crucial for ensuring workplace safety. Familiarizing oneself with OSHA requirements helps in upholding necessary safety standards.

Tailored Solutions

Tailored solutions play a vital role in meeting the diverse needs associated with fixed ladder usage. These solutions are customized to cater specifically to user requirements and construction specifications, ensuring optimal performance. The incorporation of side rails and guardrails enhances safety during access to upper levels.

Equally important is maintaining an equivalent surface width on rungs that aligns with established safety standards for comfortable use by individuals across various industries.

Industry Specifics

Different industries may have unique regulations or guidelines concerning fixed ladders, necessitating tailored approaches for each sector's specific needs. Understanding industry-specific requirements aids in customizing ladder systems accordingly, enhancing both safety measures and operational efficiency within those sectors.

Adapting fixed ladders based on industry specifics not only promotes safer working environments but also contributes towards smoother operations within diverse industrial settings.

Safety Enhancements

Incorporating various safety enhancements into fixed ladder systems further improves overall usability while prioritizing user protection during vertical ascents or descents. Examples include anti-slip rungs, non-skid coatings, or illuminated step edges that enhance visibility, grip strength, as well as general ladder usability.

These enhancements go a long way in making fixed ladders safer for users across different industries while also increasing their longevity through improved maintenance practices.

Advanced Safety Features

Fixed ladders are equipped with side rails and guardrails to prevent falls and provide crucial support. These features play a vital role in reducing the risk of accidents when ascending to upper levels or working near edges. By incorporating sturdy materials in their construction, fixed ladders ensure a secure surface for users, enhancing safety during vertical movement.

One essential advanced safety feature found in fixed ladders is the inclusion of self-closing safety gates. These gates automatically close behind individuals passing through them, preventing unauthorized access and decreasing the likelihood of falls from elevated platforms. The utilization of self-closing safety gates not only enhances overall system safety but also adds an extra layer of protection for those using fixed ladders.

Another key safety component integrated into fixed ladder systems is roof hatch guardrails, which provide protection against falls when accessing higher levels via these structures. Constructed with durable materials that resist corrosion, these guardrails offer employees a secure climbing experience while minimizing accidents at ladder openings. With roof hatch guardrails installed, workers can ascend and descend fixed ladders safely at various angles without compromising their well-being.

Enhanced Protection

-

Fixed ladders with guardrails and self-closing gates deliver enhanced protection against falls.

-

Prioritizing enhanced protection on fixed ladders minimizes accident risks during usage.

Easy Access

-

Fixed ladders offer simple access to elevated areas without requiring complex equipment.

-

They present an uncomplicated solution for vertical mobility across different settings.

Closing Thoughts

You've now got the lowdown on fixed ladders, from OSHA safety rules to advanced features. Remember, safety is no joke. So, keep your gear in check, follow the guidelines, and stay sharp up there. Don't cut corners; your life's on the line!

Now that you're armed with knowledge, don't just sit on it. Take action. Check your ladders, review your setup, and make sure everything's up to snuff. Safety isn't a one-time deal; it's a lifestyle. So, climb safe, be smart, and watch out for each other.

Contact us today via WhatsApp or email at sales@muifatt.com.my to know more about fixed ladder / cat ladder that suits your application need!

Frequently Asked Questions

What are the key features of fixed ladders that ensure safety?

Fixed ladders are designed with advanced safety features like anti-slip rungs and guardrails to prevent falls. They also include fall protection systems integrated into their structure for added security.

How can customization of fixed ladders enhance workplace safety?

Customized fixed ladders cater to specific needs, ensuring proper fit and function. By meeting OSHA requirements and considering factors like height and environment, customized ladders optimize safety in various work settings.

Why is compliance with OSHA regulations crucial for using fixed ladders?

Compliance with OSHA standards ensures a safe working environment by setting guidelines for ladder design, installation, maintenance, and inspection. Following these regulations minimizes risks associated with ladder use and promotes worker well-being.

What maintenance practices should be followed to keep fixed ladders in optimal condition?

Regular inspections for wear or damage, cleaning debris from rungs, lubricating moving parts, and promptly addressing any issues identified during checks are essential maintenance practices. Proper upkeep prolongs the lifespan of the ladder while ensuring user safety.

How do fall protection systems incorporated into fixed ladders contribute to workplace safety?

Fall protection systems such as harnesses or guardrails provide an additional layer of defense against accidents when climbing or descending a ladder. These systems mitigate the risk of falls from heights by offering support throughout the ascent or descent process.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

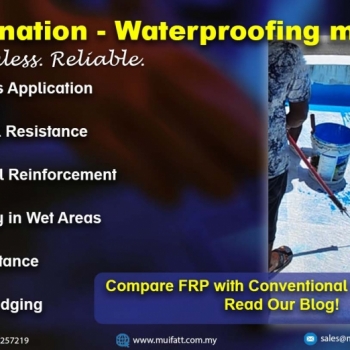

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

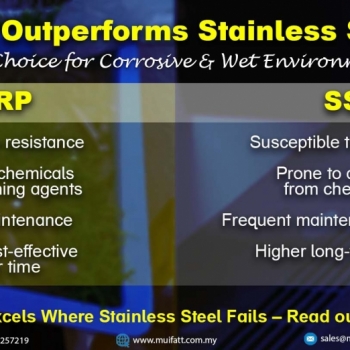

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.