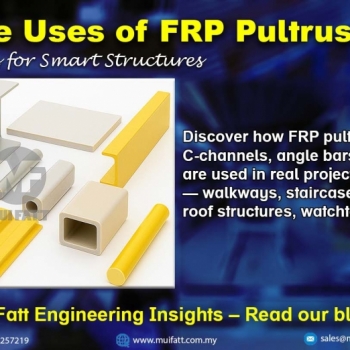

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Sump Cover Selection and Installation for Odor Control in Malaysia

05 May 2023

Sump covers play a crucial role in maintaining the integrity of sewer systems and preventing odors from arising. In Malaysia, sump covers are regulated by the Sewerage Services Act 1993 and the Sewerage Services Regulations 2014, which set out requirements for their design, installation, and maintenance.

Sump covers play a crucial role in maintaining the integrity of sewer systems and preventing odors from arising. In Malaysia, sump covers are regulated by the Sewerage Services Act 1993 and the Sewerage Services Regulations 2014, which set out requirements for their design, installation, and maintenance.

As per the Sewerage Services Act 1993 and Sewerage Services Regulations 2014, all sewage treatment plants are required to have a sump cover. The primary purpose is to prevent unauthorized access to the sump1 and ensure the safety of workers who may need to access the sump for maintenance or cleaning purpose. In addition to meeting regulatory requirements, there are other purposes for enforcing this requirement as well.

Firstly, the sump cover helps to prevent debris and foreign objects from entering the sump, which could cause damage to the equipment and potentially disrupt the treatment process. The cover also helps to maintain the quality of the wastewater by preventing contaminants from entering the sump and potentially being released into the environment.

Secondly, the sump cover helps to maintain the aesthetics of the sewage treatment plant and surrounding area by concealing the sump from view. This can be important in areas where the treatment plant is located near residential or commercial properties. Sump covers can also help with odor control by preventing gases and odors from escaping the sump chamber and entering the surrounding area.

Understanding Malaysia’s Sewerage Services Act 1993 and Sewerage Services Regulations 2014: An Overview of Key Provisions

The Sewerage Services Act 1993 is more general and sets out the overall framework for regulating sewerage services in Malaysia, while Sewerage Services Regulations 2014 provide more detailed guidance and specific requirements for different aspects of the sewerage services.

For example, the Sewerage Services Act 1993 requires property owners to connect their properties to the public sewerage system, where available, or to install their own individual treatment systems. The Sewerage Services Regulations 2014 provide more specific details on the technical requirements and standards for the design, construction, and maintenance of these treatment systems.

Factors to Consider When Selecting and Installing Sump Covers for Compliance and Odor Control

If you are looking to install new sump covers or replace existing ones, it is important to consider several factors to ensure that they meet regulatory requirements and contribute to odor control.

One important factor to consider is the size and shape of the sump chamber. The cover should fit snugly over the chamber, with no gaps or spaces. The cover should also be strong, durable, and able to support the expected loads or traffic, as required by the Sewerage Services Regulations 2014.

Another important factor to consider is the need for secure and reliable access to the sump chamber. The cover should be easy to remove for maintenance or inspection but should also be securely fixed to prevent unauthorized access.

The sump cover can be either concealed or a bar type cover, as long as it meets the requirements of the Sewerage Services Act 1993 and Sewerage Services Regulations 2014.

By selecting and installing the right sump covers, property owners can ensure that their sewer systems remain secure, reliable, and odor-free.

Benefits of Fiberglass-Reinforced Plastic (FRP) Sump Covers for Compliance with Malaysian Regulations

Fiberglass sump covers can be a good option for meeting these requirements. They are strong, durable, and lightweight, making them easy to install and maintain. Fiberglass covers are also corrosion-resistant, which reduces the need for frequent maintenance or replacement.

Firstly, FRP sump covers are strong and durable, which means they can support the weight of any traffic or loads that may be imposed on them, as required by the Sewerage Services Regulations 2014. This makes them a reliable option for covering sump chambers and ensuring they remain secure and accessible.

Secondly, FRP sump covers are corrosion-resistant and long-lasting, which can reduce the need for frequent maintenance or replacement. This can help property owners to comply with the requirement to maintain the sump chamber and access covers, as set out in the Sewerage Services Regulations 2014.

Thirdly, fiberglass sump covers are lightweight and easy to install, which can make them a cost-effective and efficient option for covering sump chambers. This can help property owners to comply with the requirement to provide access covers that are securely fixed, as set out in the Sewerage Services Regulations 2014.

Overall, the use of FRP sump covers can help property owners to comply with the regulations for sump chambers and access covers in Malaysia by providing a strong, durable, and reliable solution for covering and securing sump chambers.

Upgrade your sump chamber covers today with our reliable and durable FRP sump covers. Contact us now to learn more and ensure compliance with regulatory requirements! WhatsApp or email – sales@muifatt.com.my

Upgrade your sump chamber covers today with our reliable and durable FRP sump covers. Contact us now to learn more and ensure compliance with regulatory requirements! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – Fiberglass Manhole and Sump Covers

- A component of the treatment plant that collects and separates solids from wastewater (read more from: https://en.wikipedia.org/wiki/Sump)

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

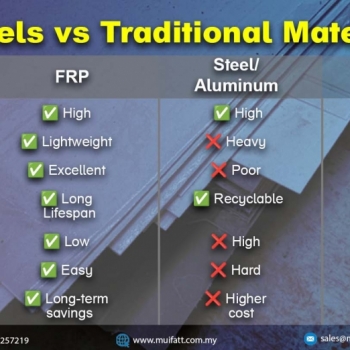

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

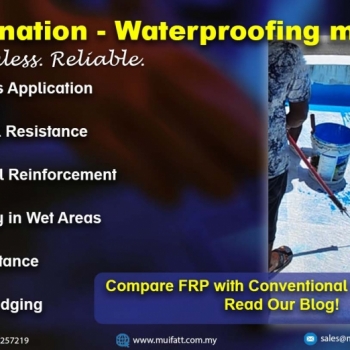

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

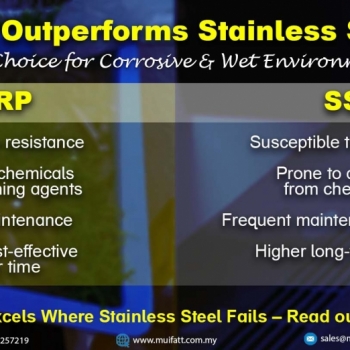

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

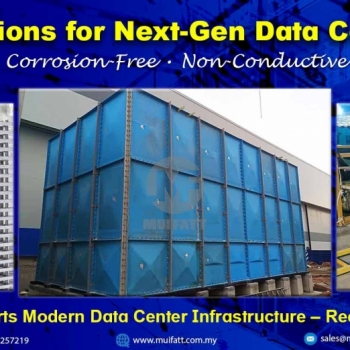

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.