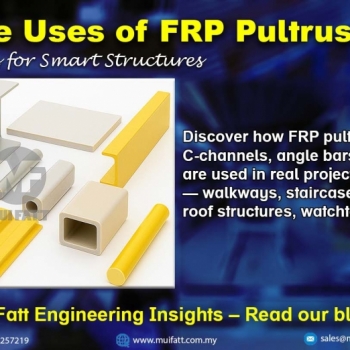

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

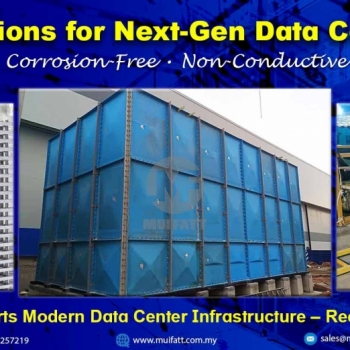

Fiberglass-Reinforced Plastics (FRP) Secondary Containment Tank

15 May 2023

A double containment system and a secondary containment tank are related concepts in the context of environmental protection and containment of hazardous materials. What are they? What is the difference between them? And what is the relationship between the two? Let’s dive into it.

What is Double Containment System?

A double containment system is by definition an arrangement of a primary storage or transportation vessels (piping system, tank system, or a combined system), contained within a housing that provides a means of secondary containment of a fluid if the primary containment fails. It refers to a more comprehensive approach to containment, consisting of two layers or barriers of containment.

A double containment system is by definition an arrangement of a primary storage or transportation vessels (piping system, tank system, or a combined system), contained within a housing that provides a means of secondary containment of a fluid if the primary containment fails. It refers to a more comprehensive approach to containment, consisting of two layers or barriers of containment.

Generally, a double containment system typically consists of both a primary containment tank and a secondary containment tank. The primary containment tank is the inner tank that directly holds the substance being stored, such as chemicals, fuels, or other hazardous materials. It is designed to safely contain the substance and prevent leaks or spills under normal operating conditions.

The secondary containment tank, also known as the outer tank or containment structure, surrounds the primary tank and its transportation vessel. Its purpose is to provide an additional layer of protection and serve as a secondary barrier in the event of a leak or failure of the primary tank.

In essence, the secondary containment tank is an integral component of a double containment system. It serves as the outer layer of containment and is specifically designed to prevent the release of hazardous materials into the environment. The double containment system, with its primary container and secondary containment tank, offers an enhanced level of safety and environmental protection by minimizing the risk of leaks, spills, or releases and ensuring that any potential hazards are contained within the secondary barrier.

In this article, we will be explore the features, benefits, and safety considerations associated with secondary containment tank, particularly in the material of Fiberglass-Reinforced Plastics (FRP).

What is Secondary Containment Tank?

A secondary containment tank is a storage system that act as a safeguard by providing an additional layer of protection. They help to contain leaks or spills in the event of failures of the primary storage tank. It shall be able to hold or contain hazardous substances, such as chemicals, fuels, or other potentially harmful materials, preventing the hazardous material from reaching the environment, water sources, or sensitive ecosystems. This containment minimizes the potential for harm to human health, wildlife, and surrounding communities. Hence, they are typically larger in size than the primary tank with a capacity that is able to hold a specific volume of the material being stored and is constructed of materials that are resistant to corrosion and can withstand the stored substance’s potential effects.

A secondary containment tank is a storage system that act as a safeguard by providing an additional layer of protection. They help to contain leaks or spills in the event of failures of the primary storage tank. It shall be able to hold or contain hazardous substances, such as chemicals, fuels, or other potentially harmful materials, preventing the hazardous material from reaching the environment, water sources, or sensitive ecosystems. This containment minimizes the potential for harm to human health, wildlife, and surrounding communities. Hence, they are typically larger in size than the primary tank with a capacity that is able to hold a specific volume of the material being stored and is constructed of materials that are resistant to corrosion and can withstand the stored substance’s potential effects.

Furthermore, secondary containment is often required by regulatory agencies and industry standards to ensure compliance with environmental and safety regulations. It demonstrates a commitment to responsible storage practices and mitigating the potential impact of hazardous materials.

Secondary containment tank often serves as a crucial safety measure. Particularly in relative industries, they are designed to meet specific regulatory requirements and safety standards to ensure the integrity of the stored materials.

Who required the use of Double Containment System?

In industries dealing with chemicals, fuels, oils, and other hazardous substances.

What kind of material is suitable to fabricate this special requirement tanks?

In the market, common materials used for secondary containment tanks include concrete, steel or fiberglass (FRP). Above all, Fiberglass-Reinforced Plastic (FRP) is commonly used as a material for secondary containment tanks because of its features.

Understanding Fiberglass-Reinforced Plastics (FRP) Secondary Containment Tank

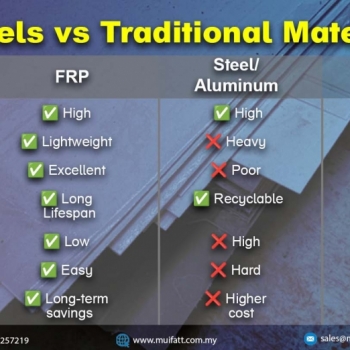

Fiberglass-Reinforced Plastics (FRP) secondary containment tank are widely used in industries dealing with chemicals, fuels, and other hazardous materials. They offer several advantages, including excellent corrosion resistance, durability, and long service life. The lightweight nature of FRP simplifies installation and transportation, reducing construction costs. Additionally, FRP allows for design flexibility, enabling customization to suit specific project requirements.

Fiberglass-Reinforced Plastics (FRP) secondary containment tank are widely used in industries dealing with chemicals, fuels, and other hazardous materials. They offer several advantages, including excellent corrosion resistance, durability, and long service life. The lightweight nature of FRP simplifies installation and transportation, reducing construction costs. Additionally, FRP allows for design flexibility, enabling customization to suit specific project requirements.

Benefits of Fiberglass-Reinforced Plastics (FRP) Secondary Containment Tank

Superior Strength and Durability

FRP materials offer exceptional strength-to-weight ratio, making them an ideal choice for constructing double containment system - secondary containment tank. Fiberglass reinforcement provides high tensile strength, allowing the tank to withstand external pressures, mechanical stress, and extreme weather conditions.

Corrosion Resistance

One of the key advantages of fiberglass is its exceptional resistance to corrosion. FRP secondary containment tank are highly resistant to a wide range of corrosive chemicals, acids, and alkalis, ensuring long-term durability and preventing leaks or material degradation.

Environmental Protection

By incorporating double containment, these tanks provide an additional layer of environmental protection. In the event of a leak or spill in the primary tank, the secondary tank acts as a secondary barrier, containing the hazardous substance and preventing it from escaping into the environment. This helps minimize the risk of soil or groundwater contamination, effectively eliminating last-minute water cut-off incident, which greatly affect people’s daily lives.

Versatility and Customization

FRP secondary containment tank can be custom-designed to meet specific storage requirements. They can be manufactured in various sizes, shapes, and configurations to accommodate different volumes and site constraints. This versatility allows for optimal utilization of available space and ensures an efficient storage solution.

Safety Considerations relating to Fiberglass-Reinforced (FRP) Secondary Containment Tanks

Proper Installation and Maintenance

Ensuring proper installation and regular maintenance of FRP secondary containment tank is crucial for their effectiveness and longevity. Following manufacturer guidelines, employing trained professionals, and conducting routine inspections are essential to identify and address any potential issues or wear and tear.

Ensuring proper installation and regular maintenance of FRP secondary containment tank is crucial for their effectiveness and longevity. Following manufacturer guidelines, employing trained professionals, and conducting routine inspections are essential to identify and address any potential issues or wear and tear.

Compliance with Regulatory Standards

Adherence to relevant regulatory standards and guidelines is vital when working with hazardous substances. It is imperative to comply with local and national regulations governing the design, installation, and operation of secondary containment tank. In Malaysia, compliance with Department of Occupational Safety and Health (DOSH) requirements is essential for maintaining a safe and compliant workplace.

Training and Emergency Preparedness

Proper training and education of personnel involved in handling and operating secondary containment tank are paramount. Workers should be trained on emergency response procedures, spill containment, and leak detection mechanisms. Adequate emergency equipment, such as spill kits and containment barriers, should be readily available to respond promptly to any potential incidents.

As a conclusion, FRP secondary containment tank offer a robust and reliable solution for the storage of hazardous substances. Their superior strength, corrosion resistance, and environmental protection properties make them a preferred choice across various industries. By adhering to proper installation, maintenance, and regulatory compliance, these tanks can provide a safe and secure storage environment while minimizing the risk of environmental contamination. Investing in FRP secondary containment tank demonstrates a commitment to worker safety, environmental stewardship, and regulatory compliance.

Talk to us for your project today! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – Fiberglass-Reinforced Plastic (FRP) Double Containment Tank

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

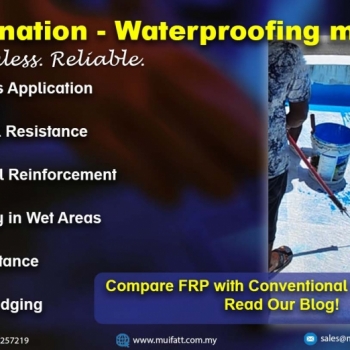

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

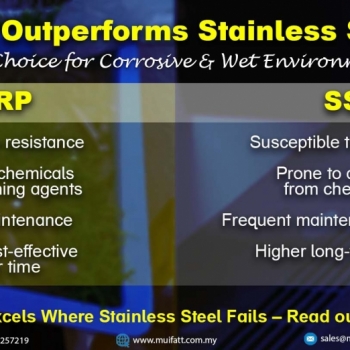

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.